Article updated November 2019 ⚙️ Integrated motors include a motor rotor and stator (in a brushless dc, servomotor or stepper motor form) paired with other motion components. About half of all integrated motors incorporate a brushless motor with permanent magnets on the rotors, though other formats exist. The most basic integrated motors consist of just a motor and drive or a motor and controller. Other add-ons can include an encoder for feedback, power supplies, cabling, and communication ports.

With the increased use of decentralized motion-control architectures, applications using integrated motors have proliferated. Consider Moog Animatics SmartMotor offerings — a line of fully integrated motors that lets design engineers setup distributed control for a variety of decentralized motion designs.

As an alternative to centralized motion control, such architectures locate the motion control on individual motion axes (in this case, to individual integrated motors) to eliminate the need for a central controller. This means that individual motors can execute the control closer to the actual axis of motion or load, thereby taking the computational burden off of a central controller and distributing it to individual integrated motors.

Integrated gearmotors power intralogistics application

Consider how some integrated motors (incorporating a gearbox with IE4 permanent-magnet synchronous motor with VFD) is driving an intralogistics application. More specifically, NORD LOGIDRIVE motors support decentralized motion design in a material-handling facility run by freight-transport service provider Toll IPEC. The facility can sort 35,000 parcels per hour … but requires an extensive conveyor system to do so. BCS chose close to 1,000 of NORD’s 92.1 series helical-bevel gearmotors with integrated ac motor+drives to get the job done. Read more about this application here.

Integrated motors make bottling machine faster

Creating a fast bottle labeling (or cupping) machine requires the design and execution of complex and dynamic ECAM movements — especially with more than 60 integrated motor+drives on a rotating platform, transferring high power and high-speed EtherCAT communication through slip rings.

This type of design would require tackling manipulators using rapid and complex control of rotating mechanics with motors and drives that operate in a vibrating, humid and extreme temperature environment. In addition, there is the requirement of transmitting deterministic and signal-integrity- sensitive communication via the slip ring media. This could involve substantial time and many weeks of intensive work, requiring high-level expertise with considerable experience. But smart motors from Elmo shorten design time to less than three days.

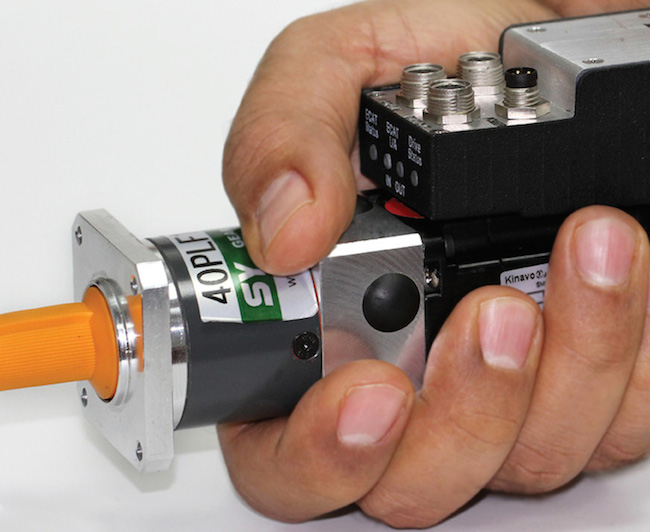

Integrated into the motors are Gold Whistle servodrives. This simplifies the indexing table and minimizes cabling to only dc bus plus EtherCAT communication cables. So the electrical cabinet is smaller too — for less EMI. The servodrive is tuned for wide bandwidth and fast response by overcoming the non-linearity of the mechanical load, making operation more stable for higher throughput. All 60 servodrives run off a Maestro multi-axis controller that controls and supervises the whole bottling process.

Bottles feed into a machine and transfer to the rotating platform, which consist of 60 small integrated drive/motor components called DUETs. The DUETs fit in the rotating platform’s limited footprint. They all directly drive bottles, which ensure precision of rotation during camera image capturing.

Engineers designed the compact motor-drive combination for tight machine spaces using high-resolution absolute feedback for precision and servo control performance. The DUETs must be rugged enough to withstand the mechanical vibrations of the rotating platform. The minimum cabling used here results in minimal external noise and low EMI and RFI.

Four cameras take snapshots of the bottles for a host computer to process and verify exact label position using an algorithm. Rotation is controlled by the Maestro, which sets the initial target labeling position and waits for the ECAM execute operation to start. All subordinate units operate in the DS-402 standardized cyclic synchronized position mode of operation. The Maestro and Elmo Application Studio (EASII) feature high interpolation levels for smooth motion trajectories with a minimum number of ECAM points. It enables fast dynamic table calculations, execution, table switching, multi-hierarchy topology building and virtual axis synchronization.

The Elmo EASII and Motion Block Libraries (EMBLs) make testing of the ECAM trajectories faster … to get machines up and running in a couple of days.

Cartesian robots for printing applications

In some instances, integrated motors find use in Cartesian gantry robotics. Consider pre-integrated Moog Animatics H-bot and T-bot gantries based on low-backlash belt-based linear actuators to deliver multi-axis motion. The SmartMotor units on the integrated design remain stationary so there’s no need for expensive cable tracks or high-flex cabling. SmartMotor programmability simplifies setup and allows direct interpretation of Cartesian coordinates (as well as transformations on the fly) to deliver precision motion and positioning output. The offerings are suitable for precise horizontal or vertical positioning of light to moderate loads.

Leave a Reply

You must be logged in to post a comment.