All ac drives (including those known as variable frequency drives or VFDs) must satisfy specific application demands. The most common of these ac drives differ from those typical for precision motion control found in robotics, semiconductor fabrication, certain types of machining, and medical instruments to output motion to sub-mm to µm and even nm scales. That’s because common servo systems use feedback and an array of dc drives to control motor-driven axes, but the most common ac drives control induction and ac synchronous motors.

Common applications include conveyor applications; lift and hoist machinery; grinding, fan, pump and compressor operations; and large machinery installations.

The most common ac drives run applications that need speed control … everything from basic functions to VFDs paired with (as mentioned) induction motors or synchronous permanent-magnet types. Such ac drives first convert ac to dc and then use switching techniques to vary voltage and frequency to the motor. Constant-voltage VFDs (which use pulse width modulation [PWM]) are most common; these feed a train of dc pulses with different widths into the motor windings with a shaped current waveform.

Machine builders often use VFDs to boost energy. Controlling current drawn by the motor can reduce energy bills because it prevents the motor from constantly running at full load. But VFDs help boost efficiency in other ways, too. With three-phase motors, they outperform single-phase induction motors (common in industrial washers and similar applications). In a similar way, VFD setups also outperform pairings of triac control with universal motors.

Some applications (including vertical arrangements and those with frequent stopping and starting) benefit from regenerative braking possible with VFDs. Here, the drive’s solid-state components (that control motor voltage) channel energy back into the ac mains or braking resistor. That boosts design efficiency and lets machinery axes slow down faster than they would if left to coast down.

Induction-motor-based motion designs that incorporate VFDs also avoid high in-rush current at startup. That’s because VFDs make it so the motor’s input starts with low voltage and frequency. There’s also less mechanical wear, as eliminating startup in-rush currents prevents excessive torque and renders throttles, dampers and louvers unnecessary.

No matter the application, all ac drives must meet key parameters, including the power-supply configuration and input voltage (and whether input is 60 or 50 Hz). Compatibility with the motor’s voltage, current rating and horsepower, as well as what speed control the application needs (closed-loop vector, open-loop vector or volts/Hz), are other considerations. Note that VFDs can introduce harmonic distortion, which degrades power quality and machine performance. However, some new VFDs address this issue.

Besides that, many common ac-drive applications benefit from ac drives that deliver safety features (brake controls and stops, for example) and acceleration or speed monitoring and limiting.

One last application parameter is that ac drives must, in some cases, withstand exposure to dust, extreme temperature and humidity. Here, drives with rated enclosures (NEMA 1 or NEMA 12 ventilated, for example) simplify selection.

Drive-motor-control boosts production by 50%

Sealed Air’s Saddle Brook, N.J., facility was both an OEM converting-line builder and equipment end user. Recently, it migrated its converting lines from an older control, motor-and-drive arrangement to boost line production. “There was some resistance from our team, but we worked with our automation partner Axis Inc. who showed us a better way,” said Tom Kimble, director of specialty equipment. Axis is a local industrial automation specialist. More after the jump.

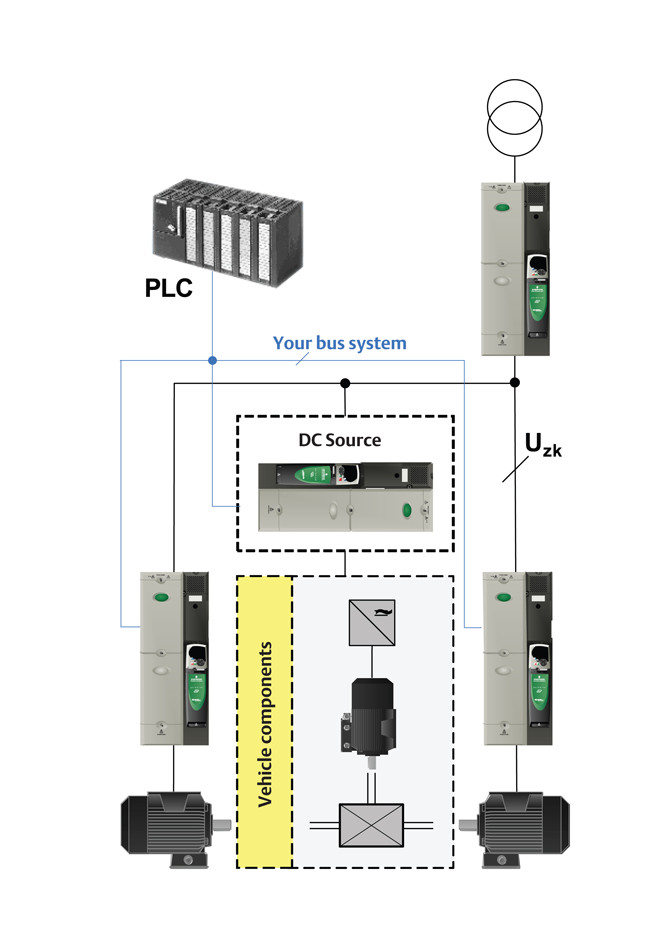

The offerings satisfy demand for inverter-based dc-source test benches for electric vehicles that reduce power consumed from the grid. Unidrive SP products connect in a common dc bus configuration to allow regenerated power (as during braking), so engineers can test whole powertrains on hybrid and electric vehicles (vehicle inverter, motor, and gearbox). For a given motor power, this minimizes the grid-connected inverter’s power rating to lower energy costs. Control loops also synchronize, which reduces the risk of system resonances.

On this project, the challenge was to boost production of Jiffy-Lite paper-sleeve (laminated bubble wrap mailers for an online retailer) from 120 to 180 bags per minute. The aim to increase output demanded more horsepower and better controls and drives. Axes had to run faster, yet with more accuracy and a smaller machine footprint to address material-handling and plant-space challenges, said Joe Pitera, motion products manager of Axis Inc.

Several previous converting lines featured a reliable motor, drive and motion control package, but the new line had to perform at levels not possible with old hardware and software.

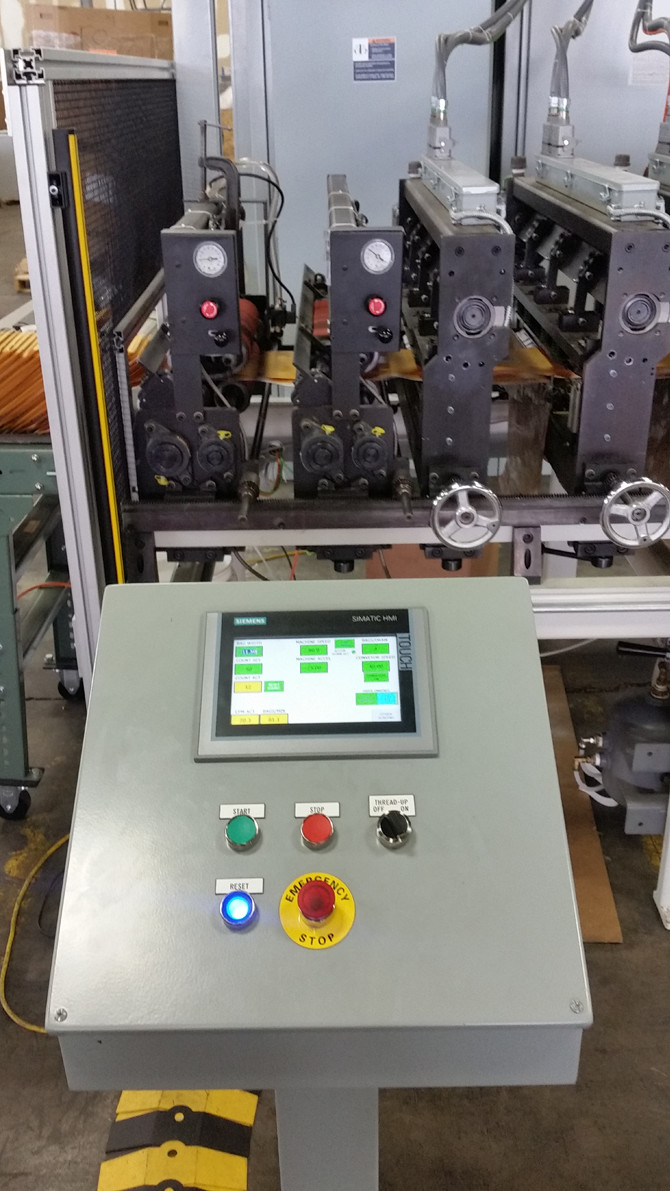

Ultimately, Axis recommended motors, drives and integrated motion controllers in a cabinet 50% smaller than the previous design. Siemens TIA Portal programming and commissioning software simplified controller integration.

“With the TIA Portal, we brought them a totally new concept in the engineering and start-up of their equipment, complete with an HMI with screens for design and subsequent runout on the devices used,” said Pitera.

“I fought the idea of a whole new engineering platform,” Kimble said. “It was so different from our previous protocols and even previous generations of Siemens products we’d used on successful Sealed Air lines. But Joe showed us the demo and how the TIA Portal pulls everything together and runs the HMI from one touchscreen with tagging, interconnects, an option-screen library and access tracking to all cable runs in the line.”

Kimble anticipated pushback. So, Pitera spent a day each week for several months at Sealed Air showing engineers multiple functions—how to copy and paste values for the entire temperature zone of the line, for example.

Implementing Sinamics S120 ac drives and Simotion motion controllers with Sinamics V20 plus using the integration features of the TIA Portal from Siemens helped Sealed Air increase line speed by 50% (from 120 to 180 packages per minute) and shrunk the control-cabinet footprint by 50%.

The new design controls 13 axes of servo motion with three simple VFDs for speed control; 16 heater zones with solid-state control and automation through the HMI; integration of 32 analog and 64 digital signals; and circuit control, safety devices and terminal blocks.

Building the design (including blocks) took less than six months. In fact, this system follows a recent build of a co-extrusion line at a Sealed Air facility in Chicago, which uses Siemens products for 43 axes of motion, 91 zones of heating, hundreds of I/O points and an HMI and controller.

Leave a Reply

You must be logged in to post a comment.