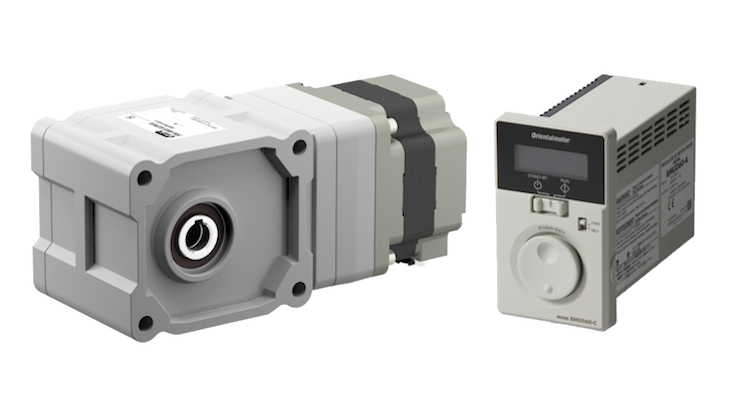

Oriental Motor has expanded its BMU Series with the introduction of the 120-W (1/6 hp) IP66 new connector type brushless motor combined with a hollow shaft right angle hypoid JH type gear head, featuring a stainless steel shaft. The right-angle hollow shaft hypoid JH gear achieves IP66 class protection through the use of a stainless steel shaft, oil ring, oil seal and new motor connector type. And because torque is not saturated, the maximum output torque is available at each gear ratio.

The BMU series brushless DC motor speed control system offers a maximum speed of up to 3,600 rpm (80 to 3,600 rpm) with a speed ratio of 1:45. This allows for a wider speed range, wider selection of gear ratios and torque ranges making the BMU Series a good alternative for servo, brushed motors or AC three-phase inverter driven applications.

Brushless DC motors compare the setting speed with the speed feedback signals from the motor at all times and adjust the motor’s applied voltage. For this reason, even if the load changes, stable rotation is performed from low speed to high speed. Unlike three-phase inverter driven motors, the torque at low speed is not limited, so brushless DC motors are suited for applications that require constant torque from low speed to high speed. Using brushless DC motors can also contribute to long lasting, maintenance free solutions, downsizing and space saving and overall energy savings.

The IP66 rated Hypoid right-angle JH gear with stainless steel shaft is currently available for the 120-W (1/6 hp) brushless motor & driver packages. The JH gear will be available for 200-W (1/4 hp) and 400-W (1/2 hp) motor models in the future.

For more information, visit www.orientalmotor.com.

Leave a Reply

You must be logged in to post a comment.