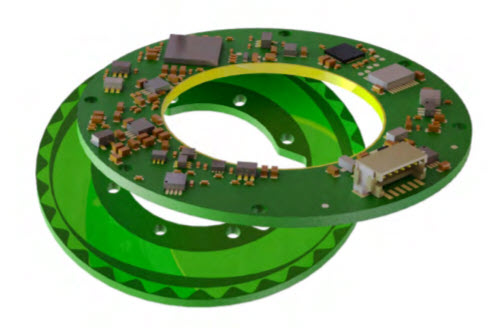

The VLX-60 is a new member of the VLX series of Electric Encoders, a product line based on Netzer Precision Motion Sensor proprietary technology. Products in this series are characterized by a number of features including:

- Low profile (<10 mm)

- Hollow shaft (stator/rotor)

- No bearings or other contact elements

- High resolution and unparalleled precision

- Low weight

- Holistic signal generation

- Digital interfaces for absolute position

- Auto calibration option

- High tolerance to temperature extremes, shock, moisture, EMI, RFI and magnetic fields

The absence of components such as ball bearings, flexible couplers, glass discs, light sources and detectors along with low power consumption allows the encoder to deliver virtually failure-free performance in nearly all types of conditions.

The internally shielded, dc-operated encoders include an electric field generator, a field receiver, sinusoidal-shaped dielectric rotor, and processing electronics. The output is digital serial synchronous with absolute position single turn.

This combination of high precision, low profile and, low weight has made Netzer Precision encoders highly reliable and particularly well suited to a wide variety of industrial automation applications.

For more information, visit https://netzerprecision.com/.

Leave a Reply

You must be logged in to post a comment.