The Interroll Group, the leading global provider of material flow solutions, will introduce new products and solutions to the Americas region at PackEXPO at McCormick Place in Chicago from October 15 to 17, 2018 (Booth E 10300). One of the highlights will be the new generation of drum motors, which Interroll is now expanding with more diameter options.

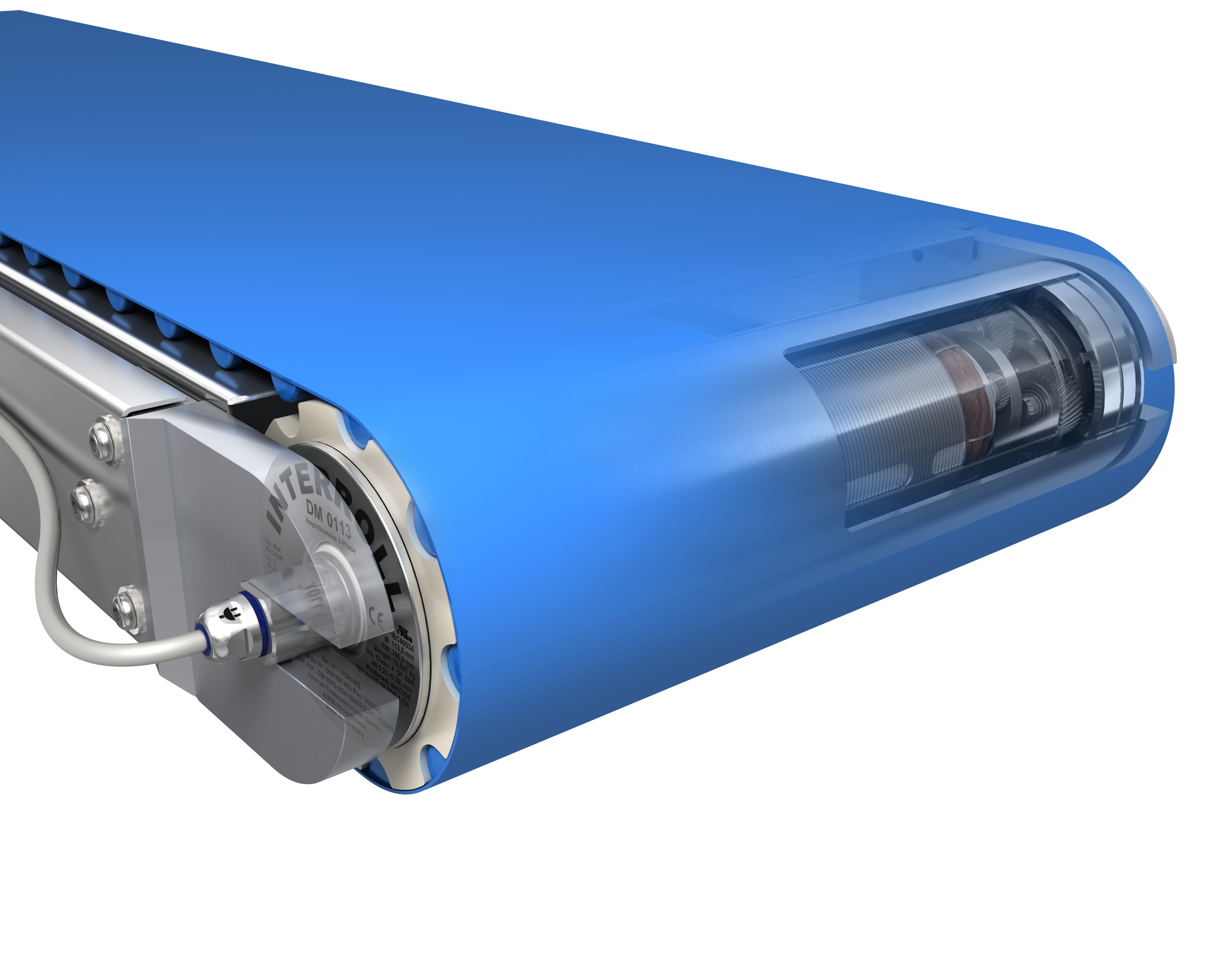

Interroll will debut the DM0113 and the DM0138—the latest addition to its range of drum motors. The new generation of drives offers an impressive range of benefits: Stronger shafts and ball bearings ensure a particularly long service life and the extremely stable design for the planetary gear allows high torques to be transferred with low levels of operating noise. All the drum motors in the new generation comply with the requirements of IP69K, the highest degree of hygiene protection, meaning that they are significantly quicker and easier to clean in comparison to traditional gear motors. Local manufacturing ensures that delivery times of the new drum motors will be kept at a minimum.

Customers seeking to upgrade their so-called blue belt conveyors will be offered exclusive new equipment: Interroll invested into new polyureethane coating equipment for producing Interroll Premium Hygienic shells for driving homogenous belts in Wilmington, USA. This solution is unique in the market.

Another highlight will be a Modular Conveyor Platform (MCP) Loop display. The MCP is ideally suited to demonstrate the ease of use and flexibility of automatic order-picking systems. The highly versatile Interroll conveyor platform has proven to be the suitable choice — as it can be adapted to the most diverse specific needs of clients and users alike.

Furthermore, it is possible to use the platform as a basis for retrofitting systems for the flow of materials in a particularly quick and practical manner. The modules, most of which come pre-assembled, made the system easy to install. The MCP is controlled by Interroll MultiControl, the new network interface card for PROFINET, EtherNet/IP and EtherCAT. With help of the MultiControl, sensors and RollerDrive are directly integrated in to the field bus level.

Leave a Reply

You must be logged in to post a comment.