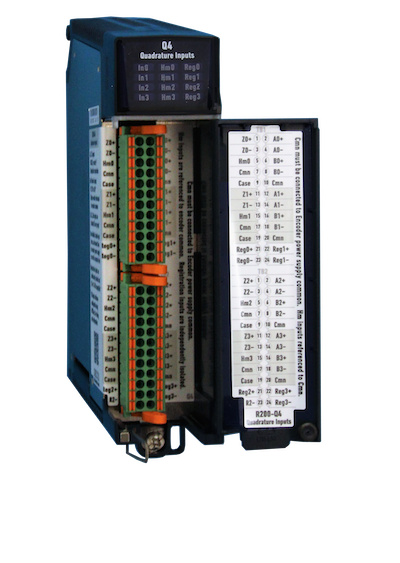

Delta Computer Systems has introduced a new quadrature encoder input module (Q4) for the RMC200 motion controller. The RMC200, which handles up to 32 axes, is the newest and most capable member of Delta’s RMC family of closed-loop electro-hydraulic motion controllers. Each Q4 module has four incremental quadrature encoder input channels (A, B and Z) supporting RS-422, HTL, or TTL. Each input channel also has home and registration inputs with 5-V or 24-V signal levels and LEDs indicating encoder faults a nd the state of the home and registration inputs.

nd the state of the home and registration inputs.

Other RMC200 modules include Synchronous Serial Interface (SSI) input, high performance 18-bit analog, and configurable Discrete I/O. For flexibility in new and retrofit applications, the SSI module can be configured to handle one RS-422 quadrature input, and the DI/O module can handle a 5-V to 24-V quadrature encoder, including one with open-collector outputs. To make it easy for existing customers, the new Q4 module, like all modules in the entire RMC family, use Delta’s RMCTools software for setup, tuning, programming and diagnostics.

“Our customers continue to love the mix and match capabilities and ease-of-use of our motion controllers, and increasingly desire more flexibility with the many axes that the RMC200 can control,” said Steve Nylund, Delta Computer Systems CEO.

With the capacity to tightly synchronize up to 32 motion axes, a single RMC200 can manage the motion of large testing or manufacturing applications, such as complete forest products sawmill production line. As with the other Delta controllers—RMC75 (which can control 1 or 2 axes) and RMC150 (which can control up to 8 axes)—the RMC200 has many special features including electronic gearing and position-pressure/force control capabilities.

For more information, visit www.deltamotion.com.

Leave a Reply

You must be logged in to post a comment.