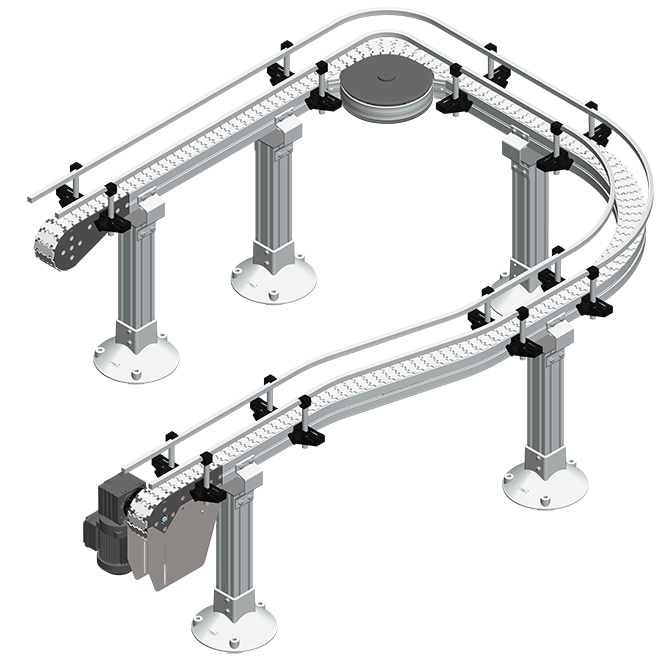

QC Conveyors now serves more markets and applications with its new Flextrac Series modular plastic chain conveyors. Their space-saving modular design lets the conveyors handle the challenges of factory automation applications — whether fitting into new spaces or integrating existing machinery.

Each Flextrac Series Conveyor consists of modular straight sections, horizontal curves, and vertical bends that combine to create an overall system customized to the customer’s exact needs. They can be built on an aluminum frame or a stainless-steel frame capable of operating in washdown environments in food and beverage packaging.

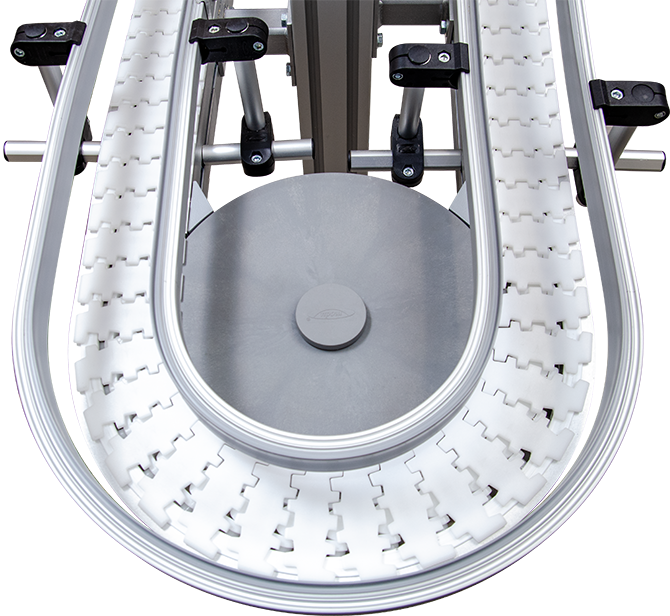

With multiple options for elevation changes, Flextrac Series conveyors can save space by taking advantage of unused vertical real estate in factory environments. In addition to traditional point-to-point system designs, Flextrac Series Conveyors can be configured into Alpine Conveyor Systems for accumulation and cooling and drying applications; or Gripper Elevator Systems for elevating and lowering product to another level or de-pucking operations.

“Modular flexible chain conveyors provide the customers a complete system solution,” said Dave Endres, President of QC Conveyors. “The new Flextrac Series delivers the modularity, reliability and high return on investment that customers expect from QC Conveyors.”

Flextrac Series components are manufactured by Modu System, a Malaysian manufacturer with more than 25 years’ experience in modular plastic chain conveyors. Customers may choose from two ordering options depending on their needs:

- Flextrac Series Components are shipped individually and assembled by the customer

- Flextrac Series Systems are engineered, assembled and tested by QC Conveyors prior to shipment, ensuring they meet the customer’s exact requirements.

Systems and components are both supported by QC Conveyors throughout North America.

With their flexible design, Flextrac Series Conveyors are engineered for a variety of applications, including packaging, automation, and part handling. They are easy to assemble or to reconfigure to accommodate changing application needs. The conveyors are capable of loads up to 850 lbs. and speeds up to 160 feet per minute.

QC Conveyors will feature a fully operational Flextrac Series Conveyor demonstration at WestPack Booth #5111 in Anaheim Calif. February 11 to 13. The demonstration includes both an Alpine and a Gripper Elevator system. The Flextrac Series will appear alongside QC Conveyors’ CBC080 Curved Belt Conveyors, HC200 Sanitary Conveyors and AS40 Automation Series Conveyors.

For more information visit qcconveyors.com/flextrac-series.

QC Conveyors is a leading manufacturer of durable and reliable conveyors and integrated systems, specializing in low profile conveyor designs and technologies. Based in Cincinnati, Ohio, they have provided customers with a broad selection of conveyor solutions for more than 35 years. Headquartered in Downers Grove, Ill., Duravant is a global engineered equipment company with manufacturing, sales and service facilities throughout North America, Europe, and Asia. For more information, visit www.duravant.com.

Leave a Reply

You must be logged in to post a comment.