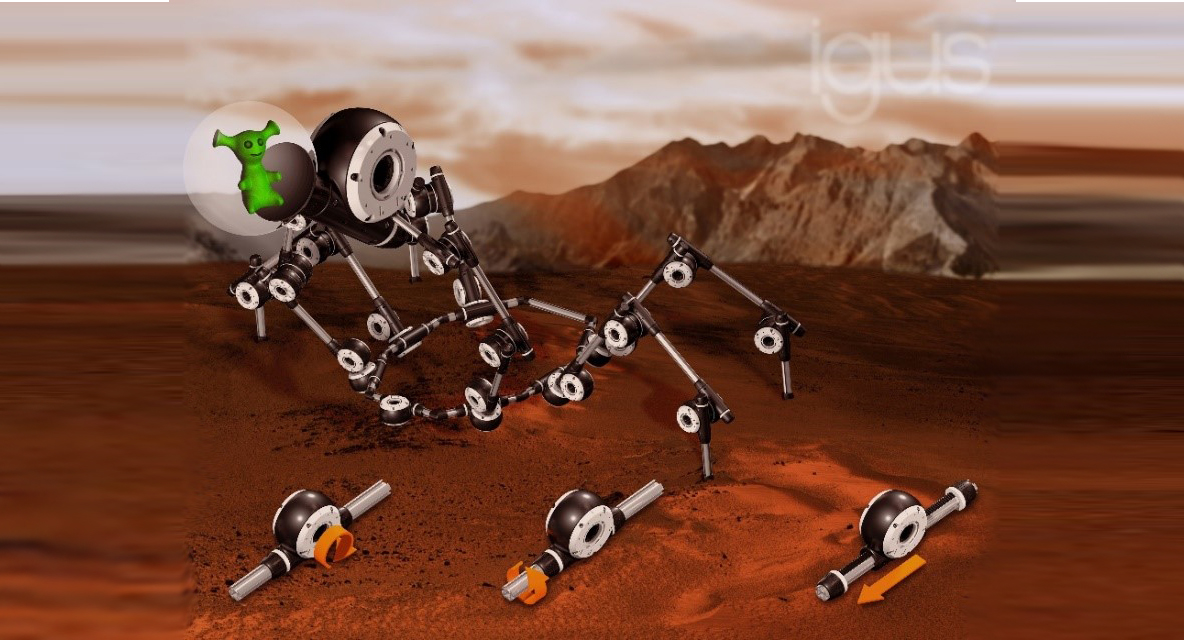

igus now sells components as part of a modular motion system called robolink Apiro. The systems could soon make designing and using individual automation setups more cost effective and much easier.

With robolink Apiro, design engineers can choose from three lubrication-free worm gears for standard, inverted and linear movement. For users, the device offers setups ranging from the simple linear robot to complex humanoid and animatronic robots. The manufacturer introduced the robolink concept at Hannover Messe in Germany in April.

Apiro, which derives from the Greek word unlimited, was developed with a focus on decoupling the motor and gearbox while also introducing new kinds of worm gears that can be installed in up to six axes, such as an articulated robot. A gearbox with linear motion, inverted and conventional robolink worm gears in four sizes come in Apiro. They can also be combined.

The new modular system will allow even complicated movements to be implemented. For example, designers needing parts for individual SCARA robots and linear robots as well as sprue pickers used in removing products from injection molding machines will see benefit in Apiro. Designers of transport and handling systems, as well as humanoid and animatronic robots which can perform movements like those of a spider, will also recognize the benefits of the new modular motion system.

The new robolink series is also suitable for training, development and research as different kinematics can be set easily and quickly.

Modular motion system leads to flexible kinematics design

The multi-functional profile enables users to connect the different gearboxes of the robolink Apiro series. Placing several Apiro joints side by side also allows for the possibility of parallel joint connections, which creates endless possibilities for many different automation applications.

High-quality tribo-polymers are used in the worm gears of the new Apiro series. The corrosion-free and chemical-resistant high-performance plastics ensure a high degree of stability, low weight, long service life and maintenance freedom.

The joints are combined by a multi-functional profile made of aluminum that makes it possible to insert drive shafts through a hollow space in the middle of the unit. The inverted worm gear makes use of that hollow space.

The gearbox allows the aluminum piece to rotate, which makes it applicable for use in robotics and rotating applications. In the case of the new worm gear with linear movement, the aluminum profile can travel linearly through the worm gear, and vice versa. Worm gears also have very little clearance.

Leave a Reply

You must be logged in to post a comment.