Nabtesco Motion Control now offers pre-engineered RH-N gearbox kits. RH-N kits use the manufacturer’s newest RV-N series of gearboxes … to 20% smaller and 30% lighter than the original RV-E series. RH-N gearbox kits make for turnkey motion solutions that trim lead, engineering, and installation times. The RH-N directly bolts onto servomotors without the need of additional components, as the gearbox kits eliminate the need to manufacture and machine motor plates and housings.

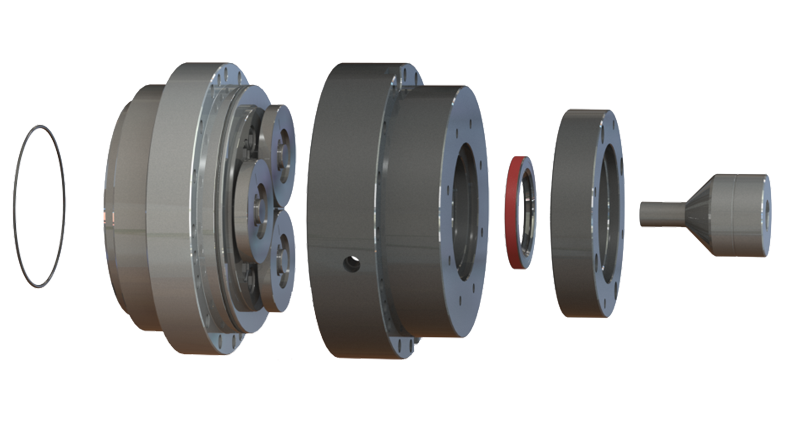

More specifically, RH-N kits include an RV-N-series gearbox; oil seals and O rings; RH-N middle flange and RH-N motor flange; all necessary fasteners; and input pinion. In fact, the input pinion requires no machining … so installers can simply bolt the design together.

Suitable applications for the RH-N include and array of servomotor-driven designs … and in fact, Nabtesco’s value-added gearbox-kit solution works on all RV-N series gear reducers with standard ratios.

RH-N Kits are designed and manufactured in the U.S. with a two-week lead time on all non-stocked items … though one Nabtesco Motion Control objective for 2019 is to increase stock levels to allow for JIT delivery.

Note: Nabtesco Motion Control RD2-S and RD2-R use legacy RV-E series gearboxes. The newer RV-N series comes in sizes that are far larger (for much higher maximum rated torques). The manufacturer anticipates a migration to the RV-N Series (and the RH-N kits) for two reasons:

- RV-N series gearboxes are smaller, lighter and more powerful than the traditional RV-E series

- Pre-engineered solutions help design engineers as detailed above

For more information on RH-N Kits (and to provide feedback or submit requests) visit this deep link on nabtescomotioncontrol.com.

Leave a Reply

You must be logged in to post a comment.