Intelligent drive technology is key to digitalization and production automation, because it enables networked and autonomous production processes in smart factories. Here, NORD DRIVESYSTEMS supplies drive solutions (hardware and software) and communications and application support for Industry 4.0 environments.

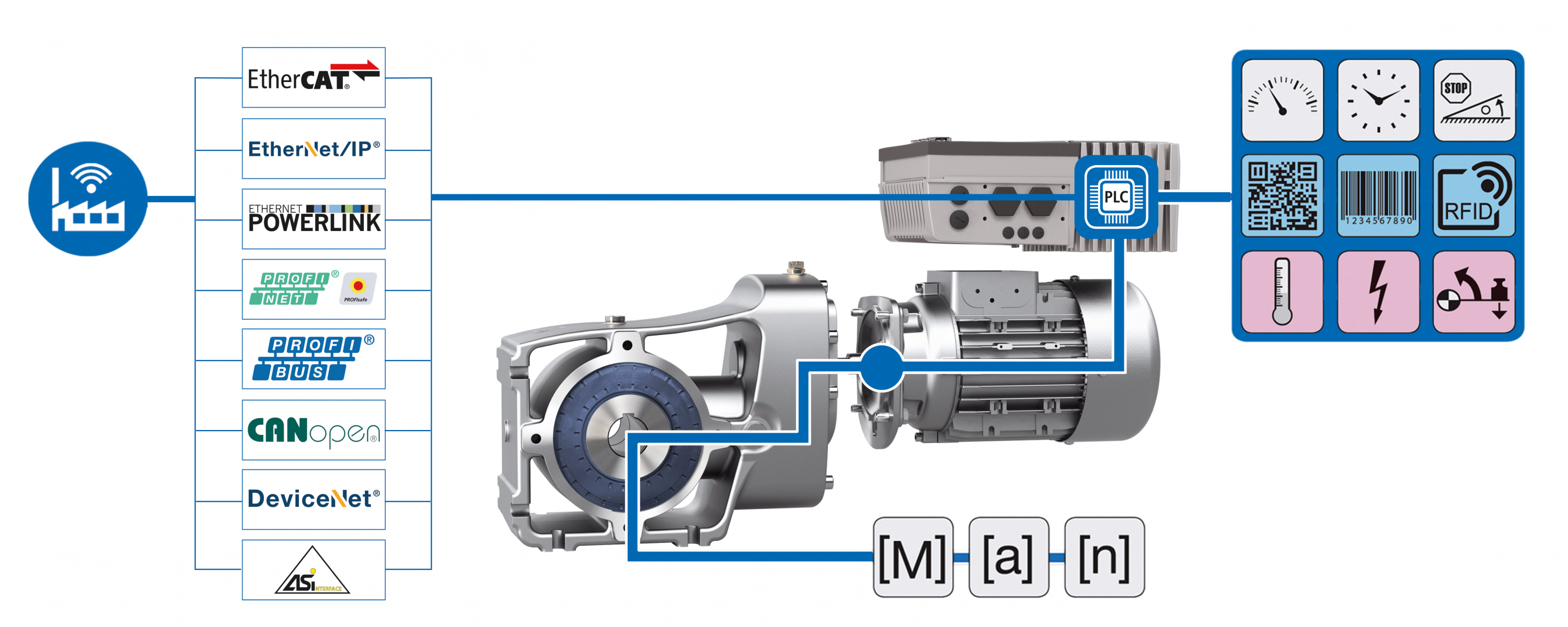

NORD DRIVESYSTEMS drive units support intelligent IIoT digitalized production with advanced maintenance services. The industrial motor drives are built for easy integration with internal PLCs and myriad communication options for decentralized motion designs. In fact, the drives work with all common fieldbuses and Ethernet-based protocols … and include analog and digital interfaces for sensors and actuators.

The integrated PLC in the drive electronics allows autonomous control of sequences and movements to reduce the computational burden on the central controls. Plus the drives facilitate scalable design to accommodate changes to automation installations’ complexity, quantity, and size. NORD drives are prepared for integration into a cloud and can be connected to various external cloud systems.

Fast, efficient and comprehensive evaluation of analogue and digital data by the intelligent PLC in the drive electronics forms the basis for modern maintenance and servicing concepts such as condition monitoring and predictive maintenance. Due to continuous monitoring of the field level, linking of communication, sensors, process data, and vital parameters of the drive, deviations from the normal state can be quickly detected. Drive operators therefore have the possibility of responding in good time before damage or breakdowns occur. Condition-oriented maintenance replaces time-based maintenance. This results in many benefits for users such as an increase in plant availability, prevention of unscheduled down times, improved planning of service and maintenance as well as a significant reduction in maintenance and repair costs.

Even gearmotor lubrication gets IoT monitoring

NORD is now investigating sensorless monitoring of oil aging and the condition of geared motors with virtual sensors. The aim is new predictive-maintenance designs to track when it might be best to change a gearmotor’s oil — based on the actual condition of the geared motor and the gear oil. For this, intelligent algorithms evaluate the operating data of the frequency inverter and determine the oil temperature from this information. Without the hardware costs for external sensors, oil aging and the optimum time for replacing the gear unit lubricant can be determined with great reliability. Tests have shown that the oil temperature as measured in tests can be reliably calculated.

NORD executes testing in Bargteheide, Germany

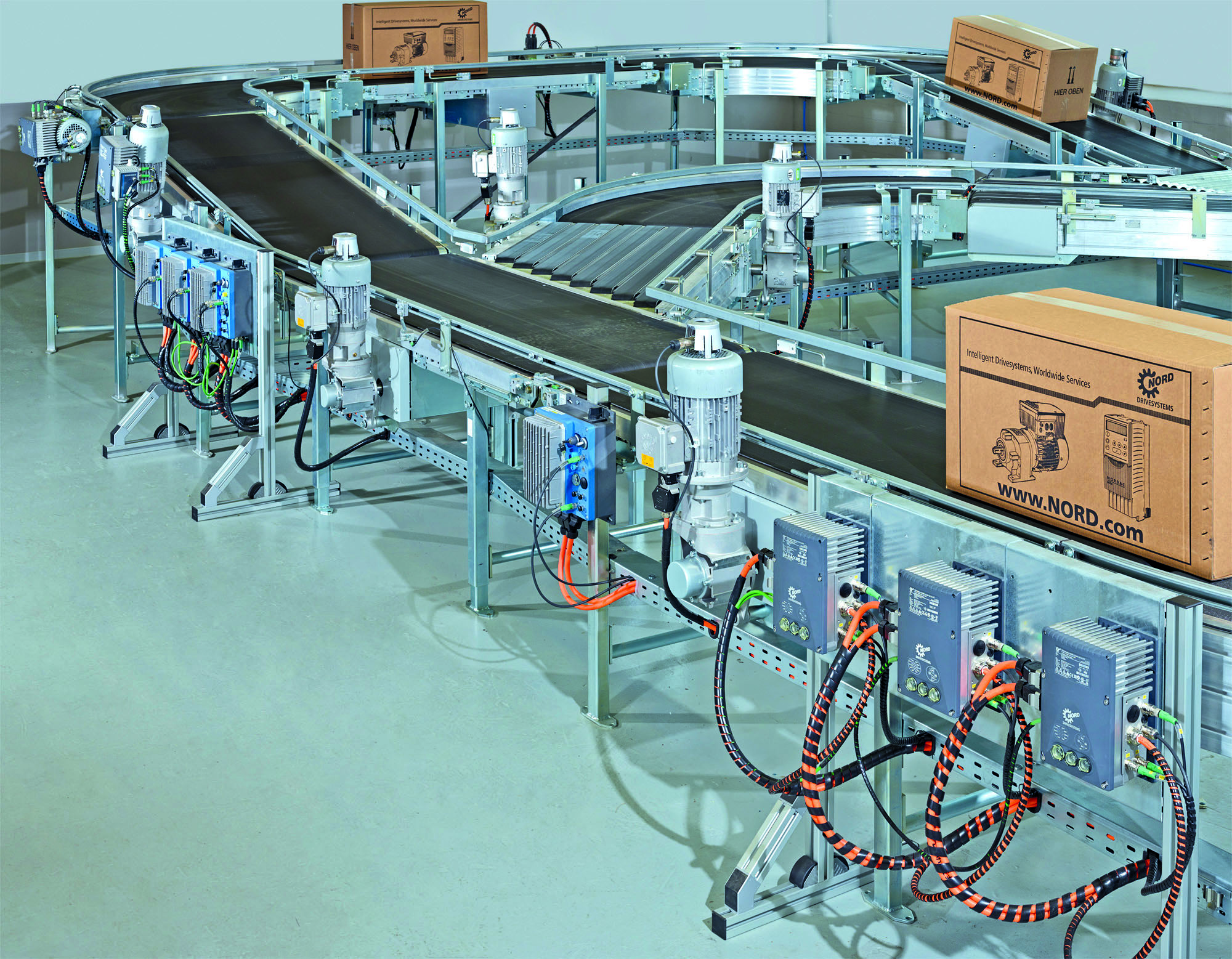

NORD DRIVESYSTEMS demonstrates an array of predictive maintenance, virtual sensor, drive networking, and Industry 4.0 concepts at an application test area at its headquarters in Bargteheide near Hamburg. With the scalable system a large variety of operating modes and operating states can be tested in real time. The test area lets visitors see geared motors and frequency inverters in action — and test algorithms under real-life conditions. For more information, visit nord.com.

Leave a Reply

You must be logged in to post a comment.