The AxCent (Axes for Centralized control schemes) product platform brings the proven and powerful performance expected of ADVANCED Motion Controls, with improvements to the design architecture that utilize years of experience in the industry and the latest advancements in modern servo system design.

The AxCent (Axes for Centralized control schemes) product platform brings the proven and powerful performance expected of ADVANCED Motion Controls, with improvements to the design architecture that utilize years of experience in the industry and the latest advancements in modern servo system design.

As technology continues its shift from analog to digital, there is still strong demand for analog designs. The reason? Analog drives provide some attractive benefits:

Simplicity.

It’s easy to train your people to set the correct switch and potentiometer settings.

Proven Track Record.

AMC have been building analog drives since their inception. They have continuously improved their designs to mirror the advances in component technology.

Performance.

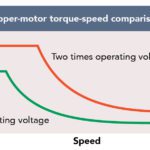

When tuned to maximum performance, analog current loops can often times achieve higher bandwidth and faster response than digital current loops.

How can analog outperform digital? It all comes down to the components. In a digital system, A/D conversions and processing time can add delays ranging from 20 to 100 microseconds. This may not seem like a lot, but in the highest bandwidth systems delays of this magnitude create a sizeable phase lag.

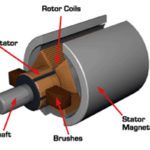

The other driving factor is cost. Large volumes and mature designs make prices attractive for everyone (except our competitors). Get more information on the New Axcent Panel Mount Brush Servo Drives from ADVANCED Motion Controls at servo2go.com.

Leave a Reply

You must be logged in to post a comment.