Here we compare these two linear-motion technologies — and hint at a common sizing error when converting to electric actuation.

By Ryan Klemetson • Business Development Manager | Tolomatic, Inc.

Hydraulics offer a long service life, but they’re not as efficient as electric systems. Electric systems also provide precise position, velocity, and speed control with more efficient operation. They operate in a closed loop environment for easy data collection, and they are virtually maintenance free.

In fact, as electric rod-style actuators become capable of delivering forces comparable to those of high-end hydraulics, they’ll become increasingly viable replacements for hydraulic systems in many applications. Evaluating capabilities and limitations and aligning them with system goals and objectives will help determine the best choice for the application.

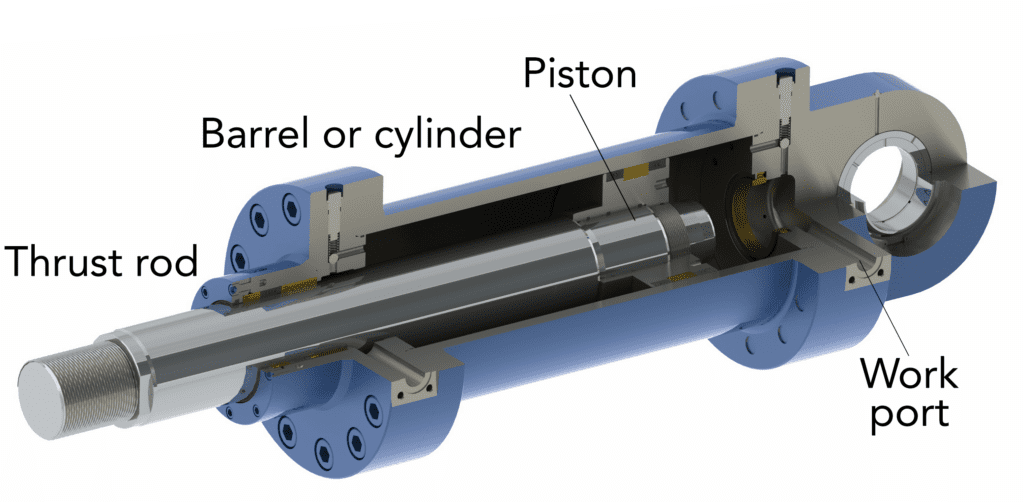

First some background: For decades, hydraulic cylinders have been the only viable technology for high-force applications. Hydraulics are rugged and relatively simple to deploy — plus provide a lower cost per unit of force. No wonder hydraulic cylinders have been the de facto choice for powering just about any heavy object that must be moved in a straight line, whether fast or slow, up, or down … including metal presses, conveyor belts, cranes, saws, and many others.

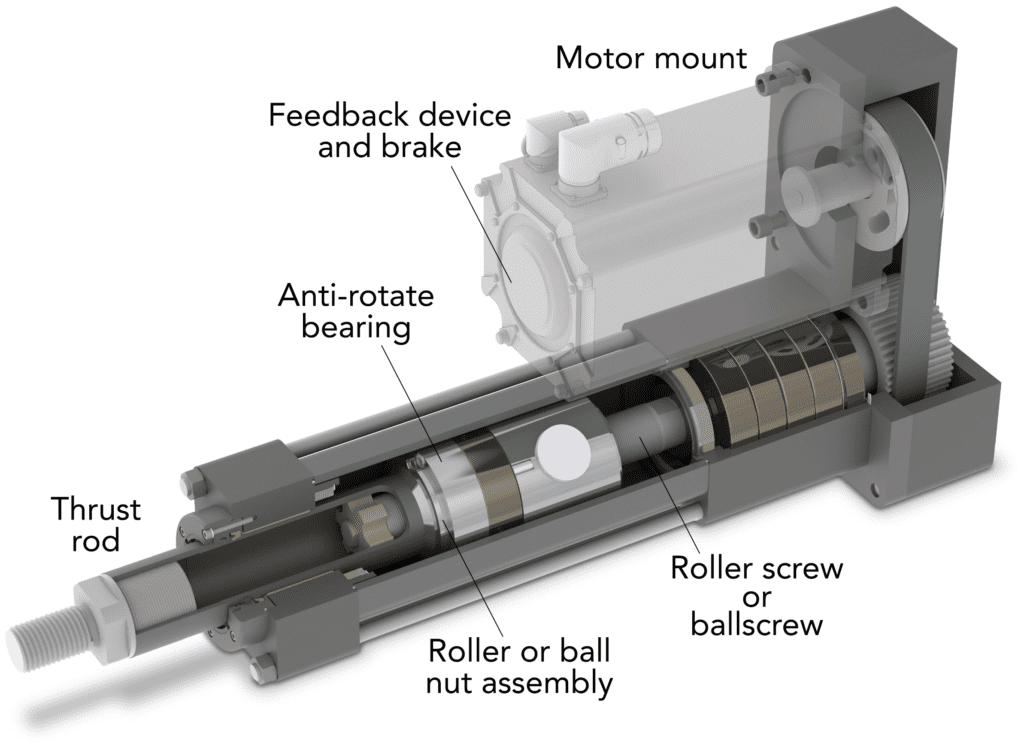

Electric rod actuators (sometimes called electric cylinders) are the newest motion technology to offer an alternative to hydraulics. Electric actuators are comparatively more flexible, precise, and reliable with ever-increasing greater force capabilities.

Understanding the advantages of electric systems over hydraulics will help determine the best choice for an application. In addition, understanding a few important tips for conversion ensure a successful transition from a hydraulic to electric-driven application.

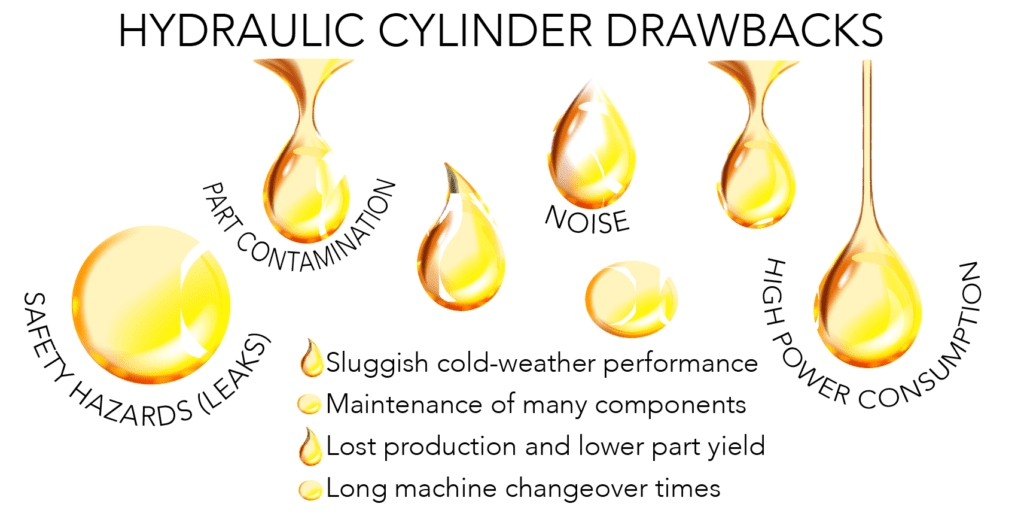

Hydraulics: A legacy technology with some drawbacks

Operators know how to keep their hydraulic machines up and running. Still, there are challenges and drawbacks. With hydraulics, it’s not a matter of if but when hydraulic systems will leak or break. Cleanup is messy and time consuming. Production parts or product may must be scrapped out. Hydraulics also need a comparatively large footprint for the compressor as well as regular maintenance and manual changeover. Plus, hydraulics are noisy, can be susceptible to temperature fluctuations, don’t have accurate multi-position capabilities, and operate open loop — which complicates data collection for use by machine controls.

Electric actuators for improved motion control

The main reason engineers select an electric actuator system over a hydraulic cylinder system is the flexibility of its motion control capabilities:

- Position control — to multiple positions with accuracy

• Velocity control

• Control of acceleration and deceleration

• Precise control of output force

• Sophisticated on-the-fly control of all these motion variables.

Electric actuators, coupled with a servo drive and motor system, allow infinite control over position … and accuracy and repeatability far exceed those of hydraulic systems.

Standard hydraulics excel in end-to-end position applications, but mid-stroke positioning with these cylinders is more complicated — and necessitate a control valve and operator assistance. Mid-stroke positioning is open loop and requires an operator to decide which position is acceptable. What’s more, speed control is monitored through a control valve and again requires an operator to dial in the acceptable speed for an application … though reaching an exact speed setting is often difficult.

Once the speed setting is adjusted, the pressure force output needed from a hydraulic cylinder is regulated through the pressure valve. Again, this typically requires an operator to dial in the target force. What’s more, a hydraulic cylinder’s repeatability of position, speed, and force are degraded by worn seals, leaks, pressure drops, and pump-induced spikes along with other maintenance-related factors. It’s difficult to get day-to-day or month-to-month (much less year-to-year) repeatable performance for production environments in which oil quality and viscosity fluctuate with temperature. Therefore, obtaining the target performance level necessitates constant operator intervention.

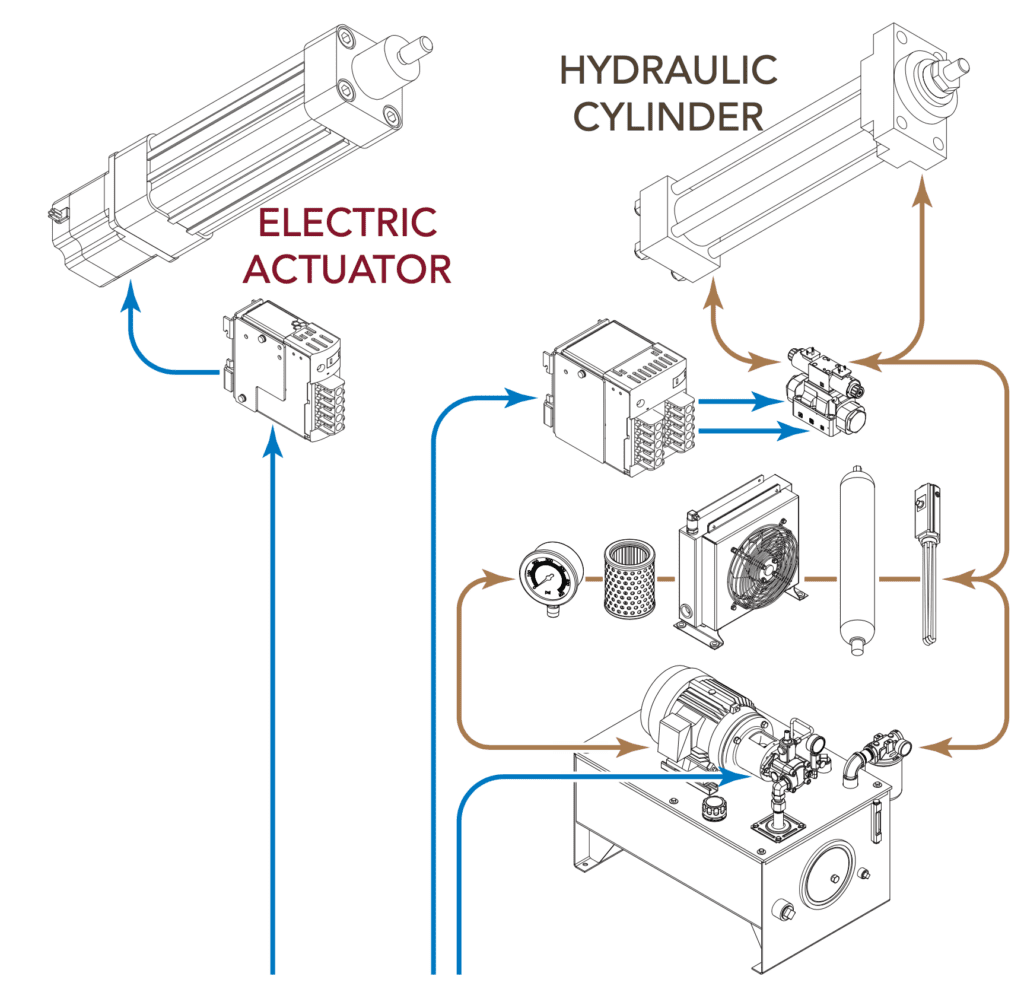

Servo-hydraulic systems need additional components

More advanced servo-hydraulic systems can precisely control position, velocity, and force, but they need additional components — a servo controller, an electrohydraulic servo valve, and a position feedback device such as a linear transducer — which adds significant complexity, footprint, and cost to a hydraulic system. These components control the pressure and flow into the hydraulic cylinder, similar to how a servo drive controls current to a servomotor. Hydraulics also have even more advanced controllers, which allow multiple axes to be coordinated together. However, this is rare in hydraulics system implementation, and these controllers add extreme complexity and cost to the overall system. In addition, they can be quite sensitive and need regimented maintenance to ensure target performance.

Servo-grade velocity control is accurate

There are even more benefits to electric actuators when they’re combined with servo control systems. Servo controllers capable of commanding multiple axes are readily available off-the-shelf components. Controllers and electric actuators can be easily (and cost effectively) coordinated in complex multi-axis configurations. Velocity of one or multiple electric actuators is precisely and continually controlled — and can easily blend from one speed to another without stopping or overrunning target positions.

In addition, servo control of acceleration and deceleration prevents electric actuators from banging into hard stops or jolting into action. This in turn eliminates stress on machine-frame elements and the need to overengineer structures to withstand shock loads. All movements will be smooth to let electric actuators impart smooth motion to mission-critical processes where machine vibrations are unacceptable or could otherwise limit process speed.

With servo systems, actuator output force is controlled via current into the servomotor. Because servo controllers have precise control over current, almost all electric actuators provide accurate and repeatable control of force output at the work point.

Another important feature of electric actuators is their ability to provide programmable control of all motion-profile variables. As a result, the only operator interaction needed is the u-front design time to build target performance variables into a PLC or other controller’s programming environment. Once set, the operation repeats from day-to-day, month-to-month and year-to-year. Human machine interface or HMI screens on pieces of equipment can display (and allow adjustment of) position, velocity, force, and acceleration and deceleration at any time for maximum machine flexibility.

Force capabilities of electric actuators

Due to their high operating pressures, hydraulic cylinder systems produce extremely high forces. Typical pressures range from 1,800 to 3,000 psi (124.1 to 206.8 bar). In some high-pressure hydraulic systems, pressure ratings up to 5,000 psi (344.7 bar) are used, further emphasizing the power density of hydraulics. Because hydraulic cylinders operate on the Force = Pressure x Area fluid-power principle, the high pressures allow smaller cylinders to reach very large forces. For example, 3-in. and 5-in. bore cylinders at 2,200 psi could reach approximately 15,000 lbf (66,723.3 kN) and 43,000 lbf (191,273.5 kN) respectively. However, hydraulic cylinders aren’t usually used to their full output force capability. Instead, they’re typically oversized to improve control.

As we’ll explore in Part 2 of this series on linearmotiontips.com, this oversizing can complicate estimations of an axis’ required force when switching to electric actuation … but careful calculations can avoid this issue.

All article images from Tolomatic Inc. | tolomatic.com

Leave a Reply

You must be logged in to post a comment.