Posidyne clutch brakes feature oil shear technology for rapid and precise stopping, starting, speed change and positioning, all without adjustment or maintenance. They are suitable for applications with frequent start/stop cycles, such as indexing conveyors that feed palletizers, rotary tables, batch feeders, rotary coal samplers, cutoff machines, and more, these unique motion control devices allow higher cycle rates (up to 300 cycles per minute), to increase production rates with lower downtime.

Posidyne clutch brakes feature oil shear technology for rapid and precise stopping, starting, speed change and positioning, all without adjustment or maintenance. They are suitable for applications with frequent start/stop cycles, such as indexing conveyors that feed palletizers, rotary tables, batch feeders, rotary coal samplers, cutoff machines, and more, these unique motion control devices allow higher cycle rates (up to 300 cycles per minute), to increase production rates with lower downtime.

Faster production rates and significantly longer service life than traditional (dry) clutch/brakes (often 5 to 10 times longer) yields increased uptime, productivity and ROI. Posidyne clutch/brakes are field proven in diverse applications such as packaging lines, food and chemical processing facilities, lumber mills, shingle plants, fiberglass insulation production, metalworking, and many more.

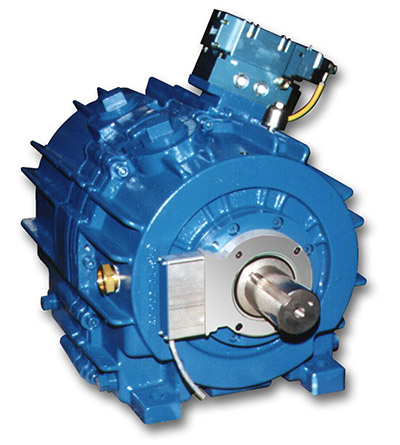

Designed with low inertia cycling components makes the Posidyne clutch brake more efficient, requiring less motor horsepower to accelerate the load, and less torque to stop the load. Their totally enclosed design is impervious to dust, chips, chemicals, coolants, caustic wash down, weather, and more, making them ideal for hostile environments.

Posidyne clutch/brakes feature a multiple disc design that produces high torque from a small package. Re-circulating the fluid dissipates the heat of engagement, which is a common cause of downtime with other clutch/brake assemblies.

A simple actuation system allows torque in the clutch and brake to be precisely controlled. Adjustment for rapid or soft starts and stops is easily accomplished. Manifold mounted control valves reduce response times by eliminating hoses and fittings, and are recommended for high cycle applications. By reducing the high starting inrush currents and the associated power factor imbalance in the motor these unique clutch/brakes can also reduce energy costs.

The Posidyne clutch brake can be actuated by air or hydraulic pressure for use in a plant or outside remote applications. The hydraulic actuation package includes a hydraulic pump, solenoid valve, regulators, and a filter. A heat exchanger can be added for additional cooling.

The Posidyne is inherently explosion proof with the addition of an explosion proof actuation valve, or locating the valve in an explosion proof cabinet. Multiple sizes are available to suit particular applications from ½ to 350 hp (99 lb-in. to 79,000 lb-in.) with cooling options, control logic and mounting arrangements to simplify and speed installation.

Oil Shear Technology is the reason that clutch brakes by Force Control last up to 10 times longer than standard dry friction clutch brakes and do not need maintenance, adjustment, or disc replacement. Oil Shear Technology is the function of a boundary layer of transmission fluid in shear between the friction discs and drive plates. As the parts come together, the fluid in shear will transmit torque between the two parts, as well as absorb heat. This eliminates direct contact of the friction discs and drive plates during high-speed slip. Heat from the friction surface is dissipated as the fluid circulates to the housing.

Heat dissipation is a major component when selecting a clutch brake. The Posidyne clutch brake basic unit dissipates heat through a unique internal design pumping system which causes the transmission fluid to be drawn into the center of the hub, flows through the friction stack, and by centrifugal force is pulled out of the stack to the housing. Cooling occurs as the fluid flows down the housing walls. Additional heat can be dissipated by adding internal water-cooling, or pulling the fluid out to external-oil-to water or oil-to-air heat exchangers. This also allows for the use of an oil filter extending the life of the fluid. These cooling options allow the same compact size Posidyne clutch brake to be used on high inertia loads, or in extremely high or low temperatures.

Force Control Industries

www.forcecontrol.com

Leave a Reply

You must be logged in to post a comment.