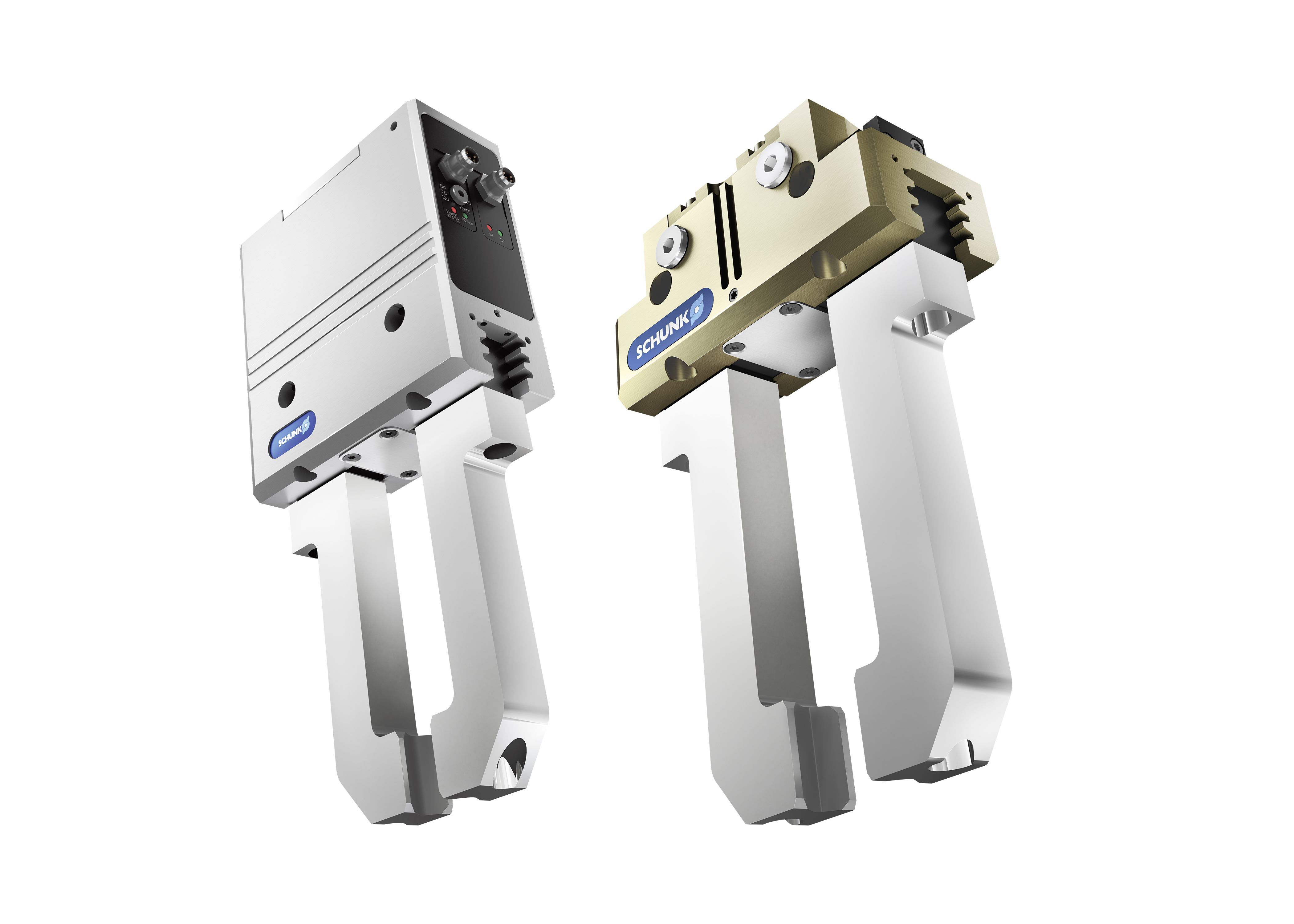

PGN-Plus-E robotic grippers

The PGN-plus-E, the world’s first digitally controlled mechatronic gripper with patented multi-tooth guidance is perfect for industrial environments. It has improved the multi-tooth guidance for higher moment capacity, a continuous lubrication pocket in the guide contour, and the proven wedge-hook kinematics with a high surface coverage in all stroke positions.

The mechatronic universal gripper is powered by a brushless DC servo motor, which leads to permanently high process stability and a long service life with minimal maintenance requirements are ensured.

The mechatronic universal gripper makes the switch from pneumatic to electric components particularly easy: it has an identical mounting pattern to its pneumatic counterpart, and the 24-V gripper is easily controlled by digital I/O. Up to two gripping positions can also be monitored by means of an additional M8 standard connection. The required control and power electronics are already fully integrated into the compact module, so no additional space is needed in the control cabinet. More after the jump.

PGN-Plus P robotic grippers

With the PGN-Plus-P, permanent lubrication is provided through continuous lubrication pockets in the guidance. For short strokes in particular, the principle of minimum quantity lubrication ensures quick and even distribution of the lubricant making the gripper nearly maintenance-free and considerably extends its service life.

The PGN-plus-P also has an enlarged drive piston area which increases grip force so that higher workpiece weights can be handled. In addition to the larger piston, the wedge drive mechanism has been redesigned for lower friction and greater surface area which transmits more energy to the jaws creating even more grip force than previous generations.

Visit Schunk at IMTS 2016 at Booth W-2000.

About SCHUNK

SCHUNK is a German family-owned company and global player in one. More than 2,500 employees in 8 plants and 30 directly owned subsidiaries and distribution partners in more than 50 countries throughout the world ensure an intensive market presence. SCHUNK designs and manufactures an unmatched selection of clamping technology and gripping

Leave a Reply

You must be logged in to post a comment.