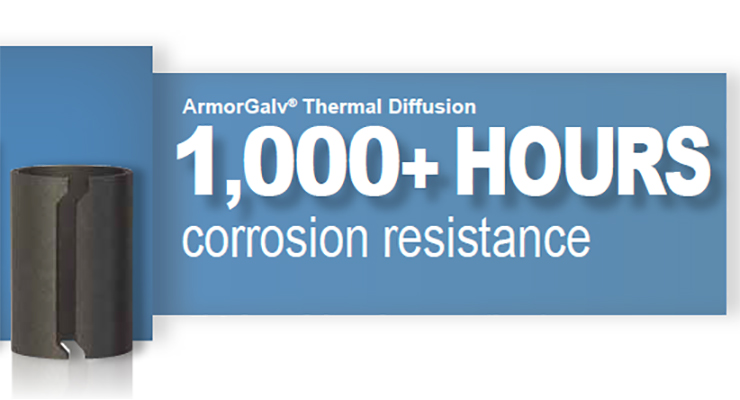

SPIROL now offers ArmorGalv®, a Thermal Zinc Diffusion coating, as a standard finish option for their engineered fasteners. This uniform deposition coating is poised to revolutionize the industrial fastener market — with 1,000+ hours of corrosion resistance, no risk of hydrogen embrittlement, and no insignificant surfaces. SPIROL is initially rolling out ArmorGalv® for their roll-formed Tubular Product lines that include Dowel Bushings, Spring Dowels, Spacers and Compression Limiters. They will offer this coating for their other products lines over the course of the next year.

SPIROL offers an array of protective coatings for their product lines to suite various application requirements, and has recently invested in the technology to bring ArmorGalv® to the market as an in-house process. ArmorGalv® not only provides a, high quality, cost effective method for maximizing corrosion protection, but it is also recognized by the Environmental Protection Agency as approaching zero emissions and has received recognition and awards for its contribution to pollution prevention.

Since 1948, SPIROL has lead the fastener industry in developing new products and technologies to address current and emerging requirements for joining and assembly. Download SPIROL’s White Paper, Features and Benefits of ArmorGalv® Thermal Zinc Diffusion, to learn more about this innovative coating and what makes it superior to traditional coatings and platings. Email info@spirol.com for more information.

SPIROL INTERNATIONAL CORP. is a leading manufacturer of a diverse line of engineered components for fastening and joining, including Coiled Spring Pins, Slotted Spring Pins, Solid Pins, Disc Springs, Alignment Dowels and Bushings, Spacers, Compression Limiters, Threaded Inserts for Plastics, Precision Shims, Pin and Insert Installation equipment. SPIROL can be found on 4 continents within the following 12 countries: Brazil, Canada, China, Czech Republic, England, France, Germany, Mexico, Poland, South Korea, Spain, and the United States. Since 1948, SPIROL has been providing technical expertise in fastening, joining and assembly to the world’s leading manufacturers.

Leave a Reply

You must be logged in to post a comment.