Brushless generators from Koford Engineering components are now possible. The motion-component supplier now sells regulated three-phase rectifier boards (for up to 5 V and 20 A) that combine with any three phase sensorless brushless motor to serve as brushless generators. Product information can be found at koford.com/Generators.pdf.

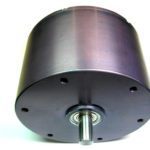

Recall that when driven by a power source (with the output leads connected to a three phase bridge rectifier diode board) standard sensorless motors act as generators. Such assemblies consisting of Koford Engineering components power up to 500 watts and input speeds to 200,000 rpm are available …

Recall that when driven by a power source (with the output leads connected to a three phase bridge rectifier diode board) standard sensorless motors act as generators. Such assemblies consisting of Koford Engineering components power up to 500 watts and input speeds to 200,000 rpm are available …

… and in fact, speeds up to 400,000 rpm have been achieved using a sleeved rotor in the frameless configuration. Applications include:

• Generators for UAVs

• Isolated electric power from compressed air

• Standard ac motors (to drive the generator using a dielectric drive shaft)

• Starter generators for gas turbines.

Sensorless motors if connected directly to a three phase load produce a three phase AC voltage equal to the input frequency times the number of pole pairs. To illustrate, the input speed of 24,000 rpm a two pole motor will generate a 400 hz output. The voltage will depend on the rpm/v and the load. Contact the factory for more details.

Four different rectifier diode boards are available from Koford Engineering for different power levels. Low loss Schottky diodes are used on the boards for highest possible efficiency; higher voltages are available.

Leave a Reply

You must be logged in to post a comment.