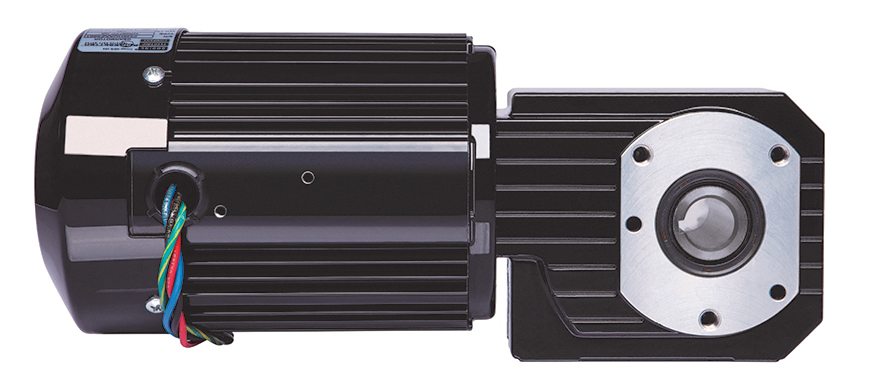

The fundamental mode of operation for gearing and its transmission of mechanical power remains unchanged — as has that for the electric motors with which they pair. But innovative variations have become increasingly common and include more custom gearing, compact designs, and better gearboxes and servogear sets (including helical gearing) for efficiency.

Gearing and gearmotors in e-mobility designs

Depending on the context, electric mobility (e-mobility) designs are:

• Vehicles with electric-motor-powered drivetrains (and their smartgrids to support fleet power demands) serving as an alternative to vehicles with internal-combustion engines

- Smaller personal-mobility designs such as scooters, e-bikes, wheelchairs, power skateboards, and even exoskeletons for military and accessibility applications

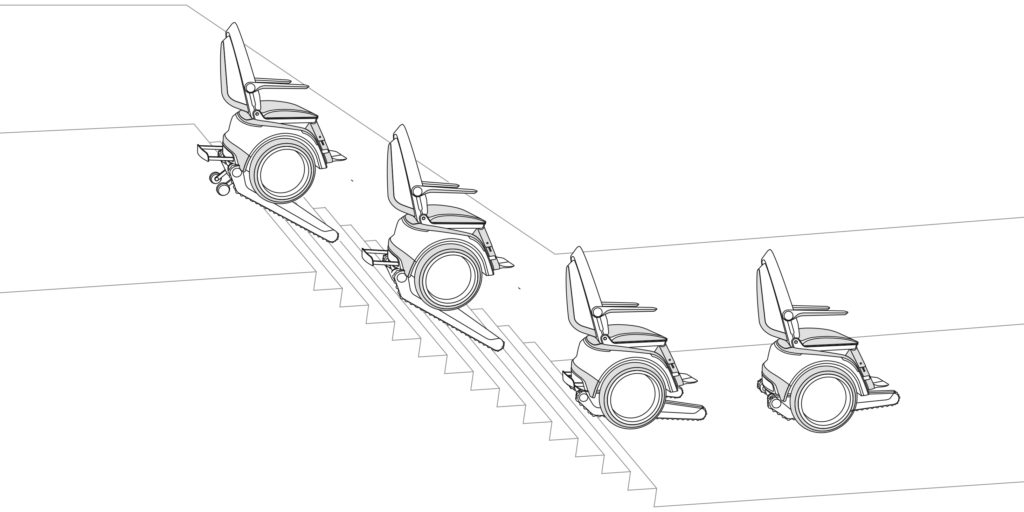

Precision drive-system manufacturer maxon Group supplies motion components for e-mobility. Case in point: A Scewo Bro wheelchair originally developed by university students at ETH Zurich (called the Scalevo while a prototype) includes two traditional wheels as well as two continuous wheels — also called caterpillar tracks — optimized with maxon motors and gearing.

More specifically, the wheelchair integrates twin 3.2-kg drives consisting of 60-mm-diamter brushless dc motors from maxon fitted with GP 52 planetary gearheads for wheel propulsion. Ceramic subcomponents in the gearhead withstand high forces and are very durable. Complementing the motor drive is a maxon EPOS2 70/10 controller module to ensure reliable control.

Climbing wheelchairs have particularly challenging design requirements, as they must safely go up curbs and even stairs to address these obstacles that are the main limits of manual wheelchairs. The traditional wheels on the Scewo Bro allow for normal operation; the continuous wheels enable stair and curb climbing by extending their bars while the tracks circulate. Sensors and cameras assess the stair geometry and then trigger automatic climbing functions to ascend at about one step per second. Once sensors detect a landing, small support wheels move into an active position to stabilize the rider and chair. Then the caterpillar tracks retract upward into a rest position and the wheelchair goes onward on its two traditional-looking wheels.

The Scewo Bro wheelchair originally deputed at the CYBATHLON — an international competition (also supported by maxon Group) in which athletes with physical disabilities use state-of-the-art technical assistance systems to compete on racecourses. Held at the Swiss Federal Institute of Technology in Zurich, events at the competition include a brain-computer interface (BCI) race, a functional electrical stimulation (FES) bike race, and races in which athletes employ powered-arm and leg prosthetics, powered exoskeletons, and powered wheelchairs.

In fact, the team at Scewo led by athlete and chair pilot Basil Dias will compete in this year’s CYBATHON as well. As of this writing, ETH Zurich together with the CYBATHLON Organizing Committee has postponed the event in an effort to curb the spread of coronavirus: Originally to be held in May, the event will now be held September 19 and 20, 2020.

“E-mobility is without a doubt a big trend that spans a range of application areas — including security and surveillance, transportation, logistics, and agriculture,” says Christian Fritz, head of business development at maxon. “As a technology leader for high-efficiency drive components, we’ve been in a prime spot to provide the industry with motors, gearboxes, and controllers.”

Over the last couple years, the portfolio of the manufacturer has grown to include battery technology, battery-management systems, and application-level controllers. “Combined with the capabilities to integrate those components into mechatronic solutions, we’ve evolved to become a solutions provider for e-mobility applications in all industries,” Fritz of maxon adds.

Update on gearset customization

The past year saw more plant and OEM engineers using manufacturer engineering software and outsourced prototyping as well as integration services. One technology that’s blurring lines between prototyping and production-quality products is 3D printing. As it’s become increasingly sophisticated, additive manufacturing has even made its way into the extremely challenging production of gearing made of nylon or polyamide.

“Selective laser sintering or SLS enables applications beyond those possible with FDM printing,” says igus DryTech product specialist Preston Souza. “The FDM process is quite a bit slower, and the tolerances are usually not that great. In contrast, we offer tighter tolerances with SLS-produced components … and shipping within three days.”

Another major benefit of these parts is durability. Testing indicates that some of these parts have wear rates comparable to those of injection-molded components — so can last almost as long … so they’re not just prototyping anymore. “These parts work for more than just verifying fit and function — and can actually run in production,” says Souza. “We’re pretty much in every industry with these components … especially in automotive, aviation, agriculture, and packaging.”

“Some trends we’re seeing are module ratios for planetary gearmotors as well as a need for smaller and more compact gearing. Efficiency improvements with reduced drag bearings and better lubrication are other areas of focus today,” says Allied Motion engineering manager Will Hellinger.

On the front of traditional metal gears and their customization, we spoke with Robert Shouppe of CGI Motion. He chatted with us about the new ways in which engineers are sizing and specifying gearing as well as trending applications for these motion components. Here’s what Shouppe had to say.

Do you ever assist engineers with verifying their design parameters?

Shouppe • CGI Motion: Yes. Engineers can of course simply call us and say, “I want to get this gearbox,” and we’ll sell them the gearbox.

But we support designers all the time who need help sizing their gearbox — and CGI Motion has lots of resources to offer exactly that kind of assistance. Our design engineering group is available to our customers to help them find the best fit for their application — be it a gearbox or gearset or gearbox assembly. In fact, supporting and supplying customized gearing is really our bailiwick in the gearbox industry — for years we’ve been known for our ability to customize. In some instances, we’ll execute a completely custom design from scratch. In other instances, we’ll take one of our existing products and modify it to fit a given application.

A third option for engineers wanting to use our products is to work with our distributors. These teams also have motion-control specialists and engineers who can help designers spec in a gearbox or motor or controller. More OEMs are choosing this option as staffs get smaller and baby boomers retire — taking their expertise out of the company and industry. Motion-control automation distributors can help machine builders facing these trends. What’s it’s interesting is that I do see a lot of young engineers just kind of looking on the Internet and picking out a gearbox and then putting it into their system … and it doesn’t work the way they want. So then they call us and we help solve their issue and get their machine axis working.

What are other mistakes design engineers commonly make in the application of gearing?

Shouppe • CGI Motion: The mistake we most frequently see is engineers initially thinking they can direct-drive their application with a motor. Then they realize at the last moment that the motor has insufficient torque for moving the application how they want.

That’s usually when they come to CGI Motion and ask us to design the gearbox to fit into what are usually very tight spaces — because after all, they didn’t allot any room for gearing. Compounding the challenge is that everyone wants to design and build everything to be as small and compact as possible.

If an axis someone tried to run with just a motor actually requires gearing, now all of a sudden you have a four-inch-long motor you’ve got move out by three inches — and you don’t have that space. So one of the things we do quite well is work with our customers to make compact designs that fit a little better into their application.

Do you recommend a certain coupling for attachment?

Shouppe • CGI Motion: Couplers from our perspective depend on how the gearing and motor mount to the application. Typically, we don’t specify the coupling type … though we do see Zero-Max and Helical products used with our gear products quite a bit. Other couplings based on sophisticated squeeze-clamp attachment are another option.

What about feedback?

Shouppe • CGI Motion: Engineers will often put an axis’ encoder on the back of the motor to track axis position. The problem is that there’s the motor and gearbox and coupler between that encoder and the actuated load — so the lost motion associated with those connections can slightly degrade the feedback information. In contrast, designs that couple an encoder to the very end of the axis (on the output side) get more exact position tracking.

We’re currently researching ways to offer design engineers yet another option — encoder feedback inside the gearbox to track the output shaft. That would also address one of the rare drawbacks of gearboxes … that of backlash. After all, the closer the encoder or other sensor is to the source of backlash, the better the control over the system.

Are belt-driven systems employing more of your gear products?

Shouppe • CGI Motion: Yes — CGI Motion’s PMX series of Primetric planetary gearheads is well suited to belt-and-pulley systems as well as rack-and-pinion actuation. The gearheads in this series have oversized bearings that are separated by a bit of space to handle the radial loading associated with belt-and-pulley actuation. Such power transmission is common in conveyor systems as well as chain-based conveyance for moving racks across an area.

Anything you would like to mention in regard to your gears’ geometry?

Shouppe • CGI Motion: We offer several gearbox families that have a low-backlash option. We cut gears to high precision to minimize backlash and achieve tight tooth mesh. We don’t do gear grinding, as our machines cut extremely high-quality gears without the need for further machining.

We’re hearing more about motion components designed to satisfy industry certifications and the requirements of environmental ratings.

Shouppe • CGI Motion: CGI Motion is ISO certified AS9100 and ISO 9001 as well as ISO 13485, which encompasses regulatory requirements for design of medical devices. We’ll soon be releasing an IP69K-rated gearbox with a ruggedized housing and heavy-duty seal system. In fact, these gearboxes are targeted to food-packaging machinery to execute wrapping and other functions.

New washdown options for gearmotors

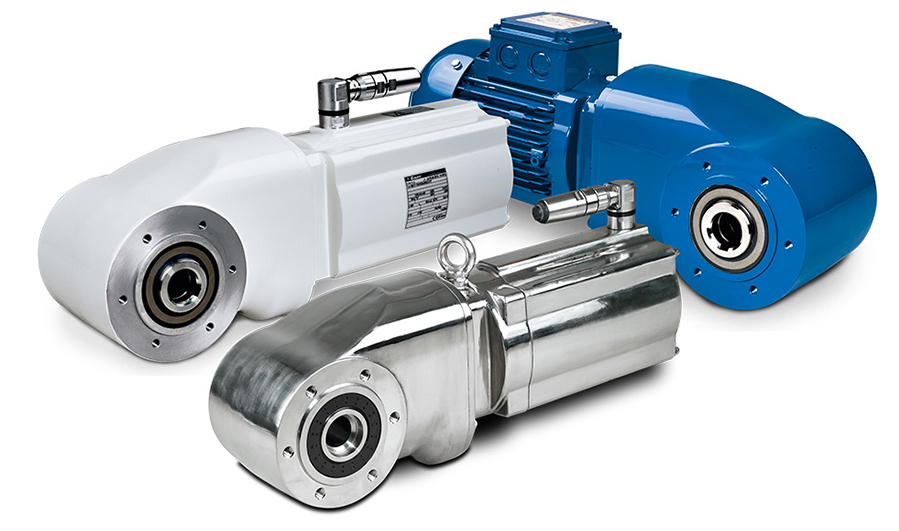

CGI Motion is joined by other manufacturers in offering new washdown-ready options. “Some of our gearmotors come with optional gaskets and seals for washdown resistance, as well as corrosion-resistant paint to protect product from environmental effects,” says Allied Motion applications engineer Mike Babala. Other examples include:

• Altra Industrial Motion Boston Gear washdown-duty stainless steel QC700 Series speed reducers with quick-connect couplings for conveyors and related equipment in facilities processing perishables such as seafood

• Bauer Gear Motor washdown-duty stainless-steel HiflexDRIVE gearmotors based on PMSM motors for facilities processing produce and more.

Gearmotor insight from two experts

We also asked Terry Auchstetter, business development manager at Bodine Electric and John Mason, manager of business development of control products at NORD Gear Corp. for their input on gearmotor trends. Here’s what they had to say.

In what industries or application areas has your company seen increased activity or demand?

Auchstetter • Bodine: We’ve seen increased activity in robotics, particularly in supplying gearmotors for robots and cobots in warehouses and automated storage and retrieval systems (AS/RS). We‘ve worked on new design projects with several manufacturers in this segment. For several years, our gearmotors could be found inside the orange robots darting around Amazon warehouses. We’re currently supplying gearmotors to another U.S. manufacturer of warehouse robots.

Besides the use of our gearmotors in a many conveyor and packaging applications, one of the more interesting recent growth areas has been the equipment for processing cannabis and marijuana. Our gearmotors are used in both the harvesting and the chemical processing of various cannabis products.

We’ve also seen increased activity in farm and agriculture applications. For example, one Bodine dc motor works in a GPS-controlled self-steering system for tractors first introduced more than 15 years ago — and still going strong. That application has developed into sophisticated new products with worldwide use. We’re currently involved in a next-generation product redesign with this OEM manufacturer. Our gearmotors are also used in planters, watering systems, and storage silos.

One last growth area is for automated ovens used by fast-food restaurants. For instance, we’re currently working on a blower motor in a pizza conveyor convection oven.

What capabilities do your components incorporate to support IoT functions?

Auchstetter • Bodine: Bodine offers a number of design options for incorporating encoders in or on our gearmotors and motors. For example, encoders are used to control the motion of the drive wheels of picking robots in a warehouse, and the data from the encoder can also be used by the IIoT system for logging the number of operating hours or miles for maintenance purposes. Bodine also can put a thermal sensor inside the motor winding so that the IIoT system can predict a failure and take steps to address it when the robot is out of service for another reason (like battery charging). Worn components tend to exert more load on the motor, which in turn increases the current draw, which in turn raises the motor temperature. That’s why a temperature sensor can provide useful data for predicting failure.

Mason • NORD Gear: NORD offers complete Industry 4.0-ready IIoT solutions for geared motor systems. Our decentralized drive systems include a PLC located in the frequency inverter. Vibration, temperature, and virtual sensors along with drive-specific parameters are preprocessed in the drive’s PLC. The data can then be shared via an Internet gateway to the Cloud.

What value-add services have you provided to an OEM or other customer?

Auchstetter • Bodine: Our engineers frequently travel to customer sites to collaborate during new product development. Early collaboration between design teams stimulates ideas and leads to the most reliable, cost-effective, and highest-performing motion control systems for OEMs. Our engineers also have the knowledge and experience to help engineers integrate components we don’t manufacture but that are needed for final drive solution —including encoders, brakes, servo amplifiers, and cabling.

Mason • NORD Gear: Condition monitoring and predictive maintenance systems using IIoT solutions are requested quite often by our OEM customers and end-users. The process of sorting and analyzing all the different data that is available (and then creating a useful tool to present all that data) can be overwhelming. NORD provides value by working closely with engineers and guiding them through the process of creating an IIoT solution that’s for their specific application.

Any new wireless connectivity options for machine designs?

Mason • NORD Gear: We’ve developed a Bluetooth Mobile solution for commissioning and optimization that interfaces to all of our electronic drive systems eliminating the need for a PC and wired connection. The free iOS and Android app provides dashboard-based visualization for drive monitoring and fault diagnosis. You can even send a service request from the app directly to a local NORD support office.

Leave a Reply

You must be logged in to post a comment.