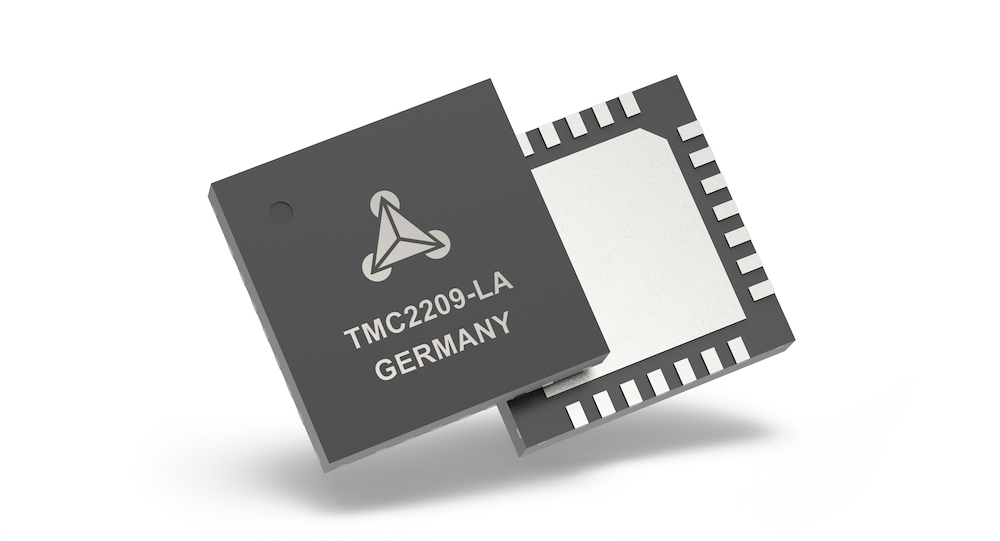

TRINAMIC Motion Control GmbH & Co. KG now sells the TMC2209 stepper driver IC — a motor driver that enables silent operation, intelligent stall detection, and lower cost for 3D printers, office and home automation equipment, and other applications using two-phase stepper motors. The TMC2209 is pin-compatible with earlier TRINAMIC devices, as well as some drivers from other manufacturers, enabling easy adoption in new designs and rapid upgrades to existing ones.

Designed to drive 2-phase stepper motors rated for up to 2-A RMS and 29-V operation, the TMC2209 integrates logic elements that support a unique wave-shaping algorithm, known as StealthChop2 and the StallGuard4 current sensing algorithm. Together, they enable noiseless operation, and sensorless homing, and additional safety features. When implemented in an application, these features provide a solid hardware platform that can be used as the basis for multiple generations of software-defined automation and motion control products.

“Since the widespread adoption of the TMC2208 in 3D printers, we’ve received lots of useful feedback from the community,” says Michael Randt, Trinamic’s Founder and CEO.

“That feedback drove many of the improvements we developed for the TMC2209, pushing the envelope on 3D printers while enabling new use cases for other software-defined, smart desktop applications. This dynamic relationship with the user community is a key part of the strategy to provide the tools and products they need to accelerate the 4th Industrial Revolution.”

The TMC2209’s pin compatibility makes it the suitable candidate for design upgrades of existing products and bringing improved applications to the market. The chip’s enhanced feature set makes it suitable for POS devices, 3D printers and conventional printers, office and home automation, textile, security cameras and A machines, as well as battery operated equipment.

Trinamic makes sure manufacturers can drive these applications into the future with the TMC2209’s fast current regulation. Optionally combined with SpreadCycle it allows highly dynamic motion control without running hot. These capabilities can be combined with the StallGuard and StealthChop2 features to provide silent running, eliminate the need for hard stops, sensorless homing, and add extra safety to applications without added cost or complexity. Together with its protection and diagnostic features, the driver IC is ready to deliver robust and reliable operation under even the most challenging conditions.

In addition to its new features, the TMC2209 offers all the advanced technologies introduced in earlier generations of stepper drivers. These include:

- CoolStep uses StallGuard measurement to adapt the motor current for best efficiency and lowest heat-up of motor and driver

- MicroPlyer Microstep interpolator for obtaining full 256 microstep smoothness with lower resolution step inputs starting from fullstep

The TMC2209 is driven through a step/dir interface with microstep pin setting. Configuration and adjustment parameters can be passed to the TMC2209 through an easy to use UART interface and stored on the device’s embedded OTP memory.

To enable rapid, cost-effective development and upgrades, TINAMIC has created the TMC2209-EVAL evaluation board, and the SilentStepStick TMC2209, a compact module for quick testing and design-in. The SilentStepStick is a fully functional, open source platform that can be used as a development tool or as the basis for an original design.

The TMC2209 and TMC2209-EVAL are available mid-June through Trinamic’s distribution channels. The SilentStepStick TMC2209 will be released simultaneously. TRINAMIC TMC2209 stepper-drive features and benefits:

- Driver for 2-phase stepper motors up to 2 A RMS and 4.75 to 29 V

- Step/Dir and single wire UART interface

- Simultaneous use of StealthChop for silent operation and StallGuard for sensorless homing and safety features

- Low power standby to fit EUP or battery operation

- Low RDSon, low heat-up – LS 170 mΩ & HS 170 mΩ (typ. at 25° C)

- Available as QFN28 or HTSSOP package for best fit

Trinamic’s state-of-the-art ICs, modules, mechatronic systems, and developer toolkits enable today’s software engineers to quickly and reliably develop highly precise drives that work efficiently, smoothly, and quietly. Trinamic is headquartered in Hamburg, Germany with a research center in Tallinn, Estonia, and Sales Engineers in both Chicago, IL, USA and Suzhou, China. For more information, visit www.trinamic.com/motioncontrol.

Leave a Reply

You must be logged in to post a comment.