Updated November 2019 ⚙️ Leading trends in electric motors for motion designs are migration to custom solutions; heightening emphasis on efficiency; and (where suitable) more use of motors that allow for miniaturization (with power-dense designs) and connectivity for IoT capabilities.

“As reshoring picks up steam, we see more mass-customization,” said Scott Evans, director of product strategy at Kollmorgen.

Here’s a bit more to illustrate what that means: “Once developing countries started catching up with the ability to mass-produce with cheaper labor, manufacturing jobs disappeared from developed countries. But today, affordable automation and CAD/CAM now let companies bring manufacturing back to the U.S.,” Evans explained.

“There’s been proliferation of communication networks for sensors, VFDs, I/O, and servos, but industrial Ethernet offers the promise of simplification and cost control.” — Doug Parentice of Moog Animatics

It’s not just mass-produced cookie-cutter production this time around, but mass-customized products now possible with minimal changeover time for ever-smaller batches.

“Even motion suppliers are figuring out how to customize quickly and efficiently, and at minimal cost. So OEMs that have an idea, but find that commercial off-the-shelf (COTS) motion products are insufficient, can now leverage co-engineering and customization with suppliers,” Evans concluded.

Product consolidation electric motors

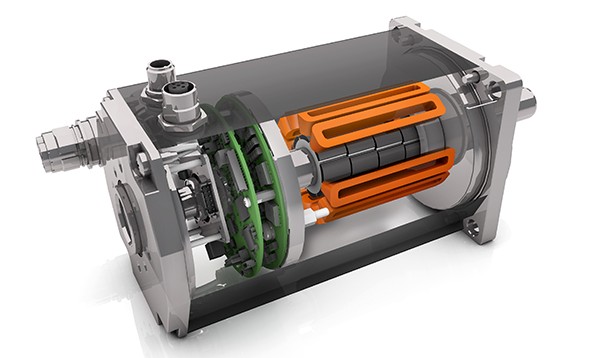

One permutation of the motor trend towards customization is product consolidation Click To Tweet One permutation of the motor trend towards customization is product consolidation, according to Brandon Steinberg, regional business development manager of Portescap in North America. Here, motor manufacturers aim to meet customer demands for more speed, torque and integration with pre-integrated setups. “So for these engineers who want to boost speed and torque, we collaborate on designs that maximize the allotted space for high power output and efficiency,” Steinberg said.

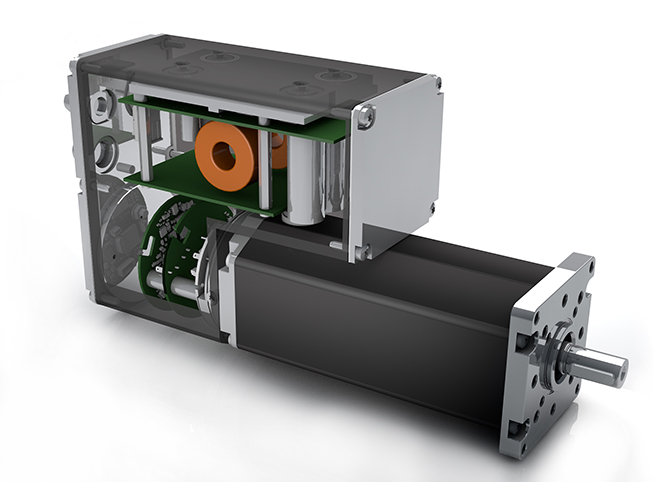

Consider a related trend specific to brushless dc motors—integration of controls. A growing array of web-based configuration tools let designers pick such motor-control pairings more easily.

More overlap between electric motor types

Integrated motion is a leading trend in stepper motors as well. Here, combining the stepper, drive, controller and encoder simplifies installation. In addition, control techniques such as hybrid Motion Technology (hMT) help stepper motors maintain their advantages of torque density, lack of jitter at standstill, and the ability to work without tuning, while delivering the reliable synchronization, torque control and cooler operation of servomotors. That’s according to Clark Hummel at Schneider Electric Motion.

Torque control for steppers (now possible with hMT) even lets steppers work on axes for winding, capping and clamping tasks once impossible because of stalling and loss of synchronization.

Other lines between which motor types are suitable for which applications are blurring. “Over the past decade, the use of variable-speed drives has dramatically increased for all applications,” said Will Delsman, inside and technical sales manager at NK Technologies. The company manufactures sensors to measure current, voltage and power for industrial automation machinery.

More specifically, field-oriented sensorless vector-control-based drives have become commonplace, with both vector and voltage/hertz outputs available from the same drive. “Here, we see ac servos running positioning and product motion where only dc servos were used previously,” added Delsman.

Application-specific motors could reign supreme

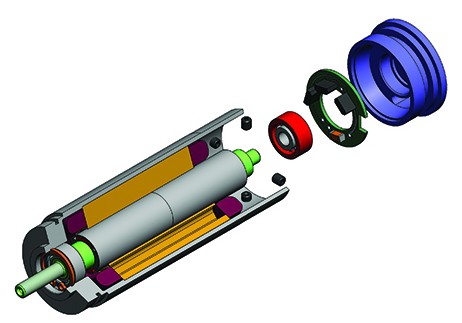

Mass-customized motors often take the form of application-specific iterations. Here the catch is that motor designers must get as familiar as possible with end applications to help optimize performance, according to Matt Marrow, business development manager with Portescap. Only then can they tailor materials, magnets, construction and manufacturing processes to satisfy OEM specifications.

Case in point: Packaging and food and beverage demand cleanable motors, but legacy stainless-steel servomotors were expensive and big and often weren’t much more reliable than standard servomotors. Now, demand plus the Food Safety Modernization Act (FSMA) are forcing manufacturers to make these motors more durable.

Another example of function driving application-specific motor design is in the passenger railway and subway car market. This industry has historically used brush dc motors for automatic door actuation, but such motors failed and added complexity, due to the separate controls and associated wiring that had to run through the car, said John Morehead, national sales manager at Crouzet Motors and Crouzet Automation, brands of InnoVista Sensors.

“In response to the railway industry’s need for longer-life automatic door systems that are easier to install and control, Crouzet Motors developed DCmind brushless gearmotors with CANopen networking capability,” he said. “The gearmotors (because they’re brushless) last longer than the brush dc motors they replace, and (with integral controls) eliminate extra installation cost and complexity associated with brush dc motors and separate controls and wiring.” CANopen makes for economical and easy networking using a simple two-wire system.

There’s yet another example from the medical-device industry. BEI Kimco linear-voice-coil actuators now have integrated position sensors. “We’ve developed housed linear actuators for ventilators and heart-valve life-test fixtures that survive more than 100 million cycles,” said Jim McNamara, BEI Kimco senior applications engineer.

Just 10 years ago, we started manufacturing housed actuators. “Now, our housed actuators provide reliability that our customers need and would’ve had to develop on their own,” he added.

Affordability in motors and control electronics

Others acknowledge specific examples, but say the move to motor-feature integration is a pan-industry trend. “Decreasing cost with increased subcomponents and electronics integration is driving motion-component innovation more than the demands of any single industry,” said David Marks, motor engineering and research manager at Moog Components Group.

In fractional-horsepower motors, Ed Tullar, sales manager at Groschopp, sees the increasing affordability of controls, electronics and sensors driving demand. Falling prices of rare-earth elements have also made the manufacture of myriad power-dense motors once again price-competitive.

On another front, Moore’s Law has enabled many applications that were unaffordable 10 years ago, as new controls now let engineers use traditional motor and power-transmission technologies for ever-more-sophisticated motion designs.

“Motion control has so improved that error—actual motion versus commanded motion—is now controllable to the 1-µsec range by electronics mounted on or a few meters from the motion,” said Evans. “So, phenomena such as jitter and lag that were huge issues a few years ago are less significant issues now.”

Consider drive-by-wire designs.

“We can fly drones over targets of interest from one control center thousands of miles away using cable-TV satellites and COTS consumer electronics at both ends of the communiqué, and lag is less than a second. All of this was impossible 10 years ago,” said Evans. In fact, the same technologies now go into everything from multi-plant processes, such as refining to driverless vehicles for mining and other exploration tasks.

“Even ultra-simple applications, such as slow labeling machines, can have far simpler mechanicals because higher-performance motion is now more affordable,” continued Evans. “So if an OEM can buy a stepper system for the same price he once paid for a mechanical clutch, for example—well, why wouldn’t he do that?”

That’s especially true when end users of such a machine expect accurate label placement and zero scrap, and longer machine life by virtue of fewer wear components, but don’t want to pay more for the new version of the machine.

Related articles on trends in motor technology

Updated: Trends in electric motors Part I — Miniaturization, connectivity, and customization

Updated: Trends in electric motors Part V — Research laboratories drive technology convergence

Leave a Reply

You must be logged in to post a comment.