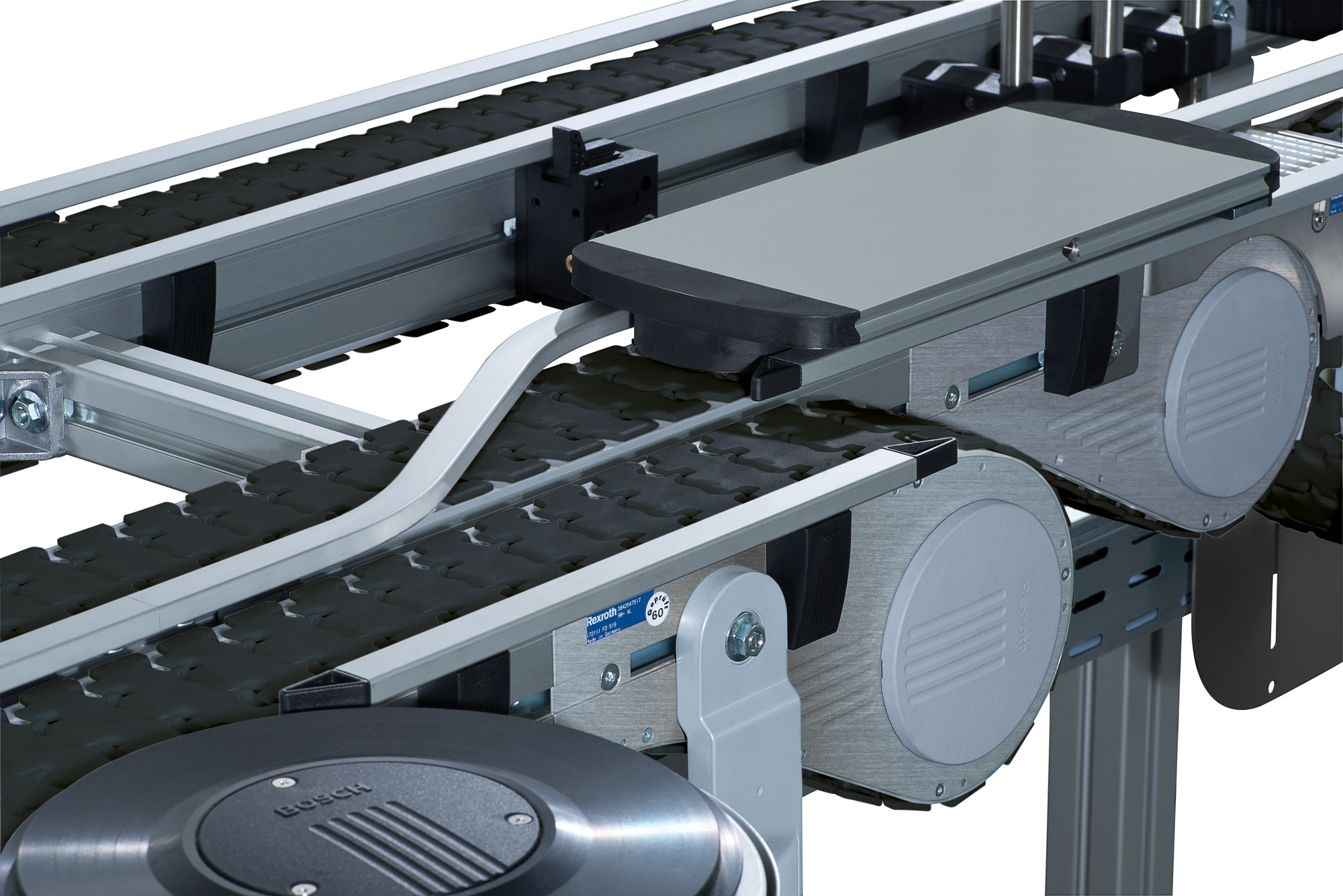

Rexroth’s VarioFlow plus enables diverse applications —from general machine interlinking to food and packaging — to transportation tasks in difficult environments.

With the upgraded modular system of the VarioFlow plus chain conveyor system, Rexroth now offers users a series of standardized solutions for specific conveyor functions, which simplifies the fast implementation of customer-specific designs. The application spectrum now includes everything from simple machine interlinking to special ESD solutions in the electronics industry, as well as secure transportation tasks in abrasive environments and stainless steel designs for food & packaging.

In virtually every industry, a competitive advantage depends heavily on short time-to-market. Rexroth’s VarioFlow plus chain conveyor, thanks to its ability to achieve easy and fast implementation of diverse, complex transportation tasks, provides an ideal basis for faster product introduction. The system enables flexible, customized solutions, saves space and is low-noise. In addition, the MTpro planning software supports fast project planning and with it, the ability to make short-term adjustments to changing market requirements.

The time and cost-saving Rexroth chain conveyor system ensures competitiveness by enabling fast time-to-market

- New drive and chain variants for a wide range of applications

- Powerful ESD system in two sizes

- Pre-designed, drop-in modules simplify project planning and assembly

With the latest upgrades to the offering of this modular system, users can now benefit from VarioFlow plus in the area of sensitive electronics production, as well. The ESD system ensures the safe avoidance of electrostatic build-up, offers a high chain tensile strength of up to 600 newtons and can also be used in applications requiring workpiece pallet systems.

For use in abrasive environments, the system now includes new compact clean-rated conveyor section profiles in stainless steel and stainless steel slide rails. They ensure that falling particles capable of causing extreme wear are carried out of the system immediately. Moreover, users can transport sharp-edged products directly on a steel-plated conveyor chain.

The new drive concept contains a center drive and a transmission kit, with which a direct drive can easily be upgraded to a transmission drive. Rexroth offers a low-cost solution especially for accumulating buffer applications: with the 90° return unit, users can significantly reduce the need for return chain. New chain types also ensure safe transport of a wide variety of products: the flocked chain protects delicate component surfaces, the gray chain minimizes optical distractions, and roller cleats protect product surfaces in ascending and descending conveyor sections.

Based on comprehensive application know-how, Rexroth has developed drop-in solutions for specific conveyor functions, such as a mechanicallycontrolled traffic barrier for conveyor section junctions. These ready-to-use components simplify the implementation of customer-specific systems for the user, without the need to spend great effort on planning.

Leave a Reply

You must be logged in to post a comment.