In a recent video with Lee Teschler, we go over three torque limiters from Mach III — a Kentucky-based manufacturer of stock and custom brakes, clutches, and torque limiters. The manufacturer can usually deliver custom designs within two days of obtaining application requirements. Mach III also meets or beats purchase-order ship dates 98% of the time. Catalog products ship in 2 to 5 weeks and custom in 3 to 6.

Recall that friction torque limiters transmit a set torque from the motor end of an axis to the driven-load end — and protect both from overload. Should torque exceed a set value, the torque limiter slips.

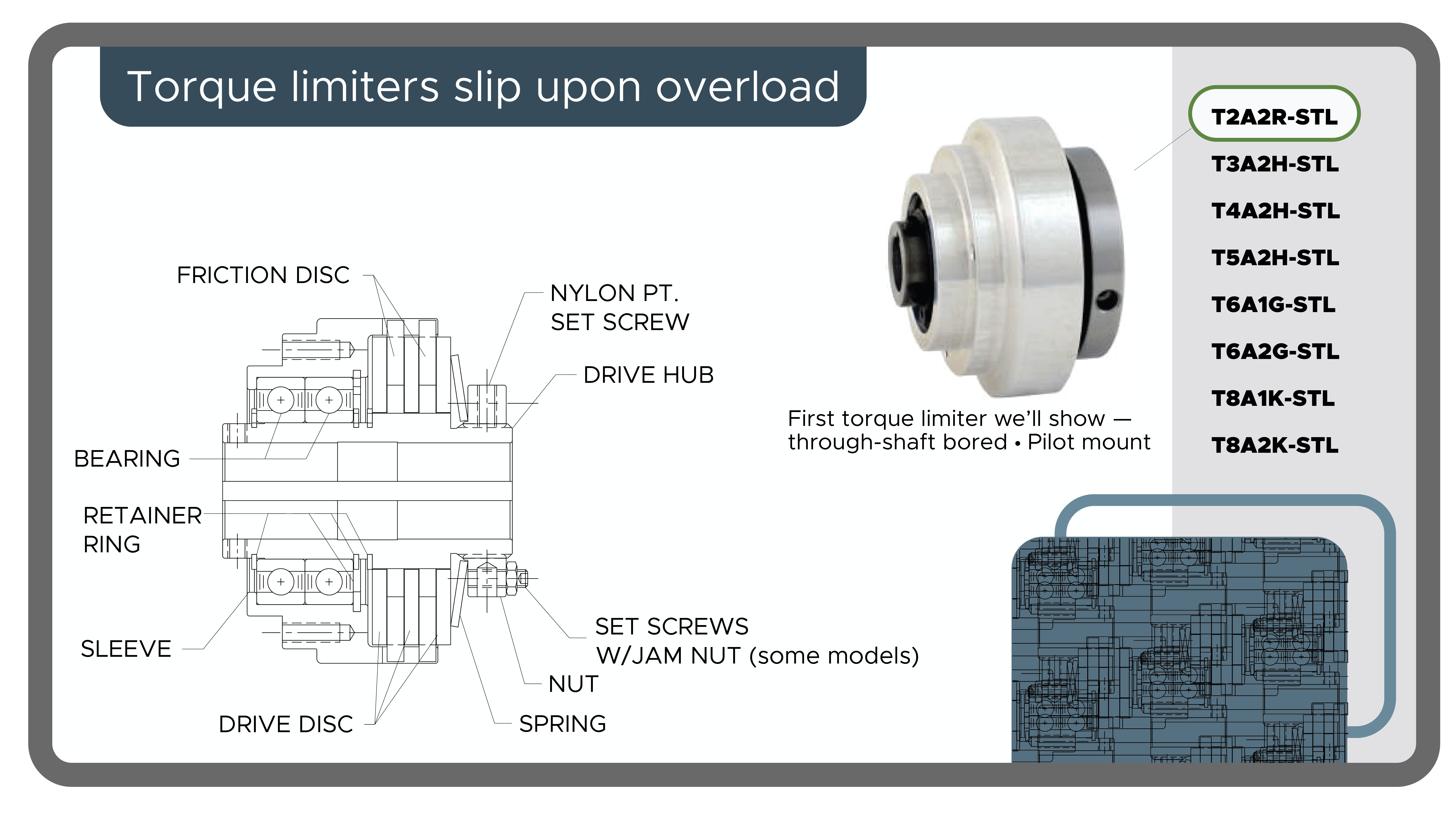

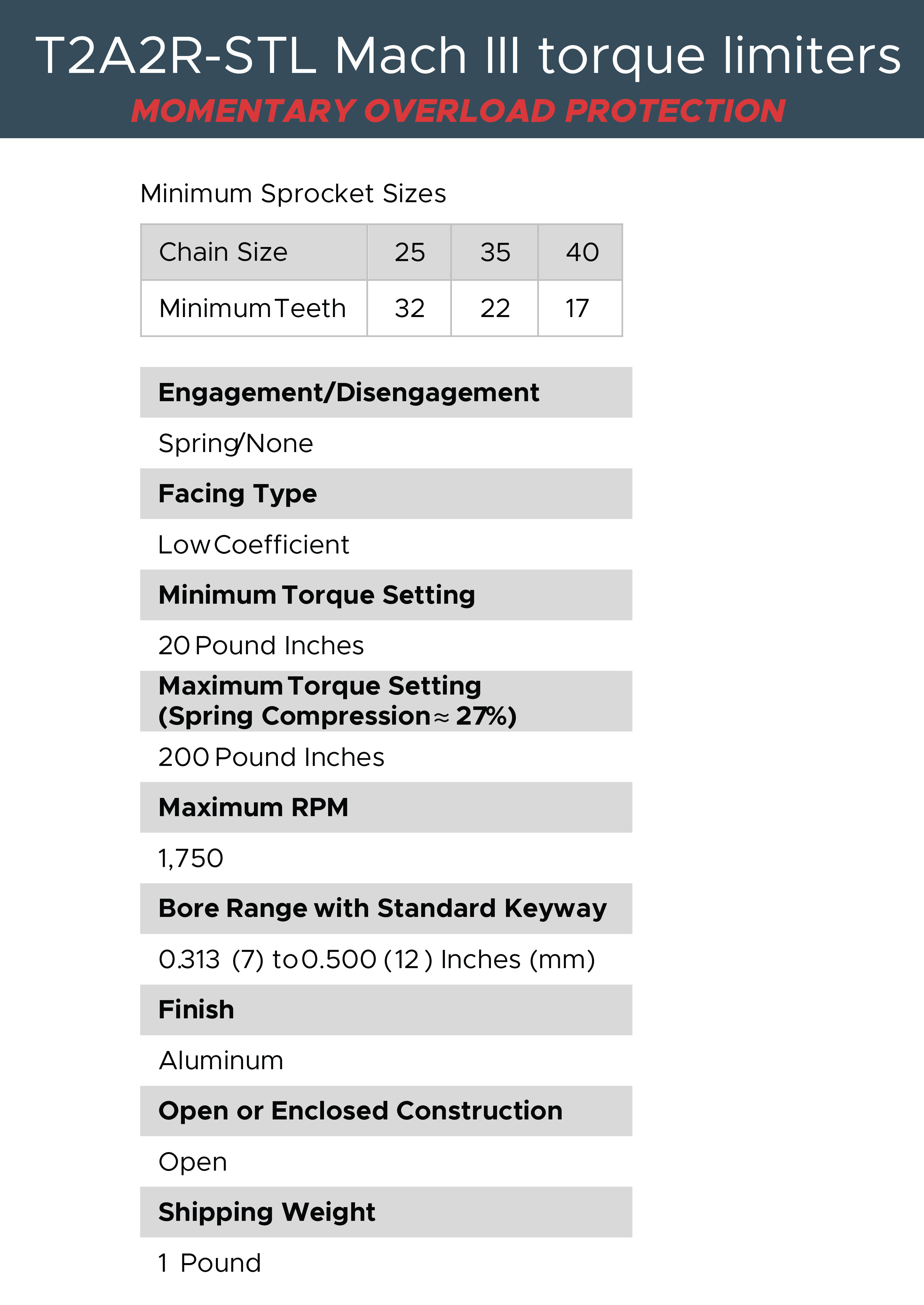

So let’s check out our first sample — a T2A2R-STL mechanical torque limiter … on which a sprocket, pulley, or sheave can mount. This is a spring-engaged design having low-coefficient friction discs. Minimum torque is 20 lb-in. and maximum torque (with 27% spring compression) is 200 lb-in. This one-pound torque limiter works on axes with speeds to 1,750 rpm.

Of course, torque limiters can integrate into motion systems in a few ways. We just considered one that accepts input via a sprocket-and-chain or pulley-and-belt assembly. Now let’s consider one for shaft-to-shaft mounting.

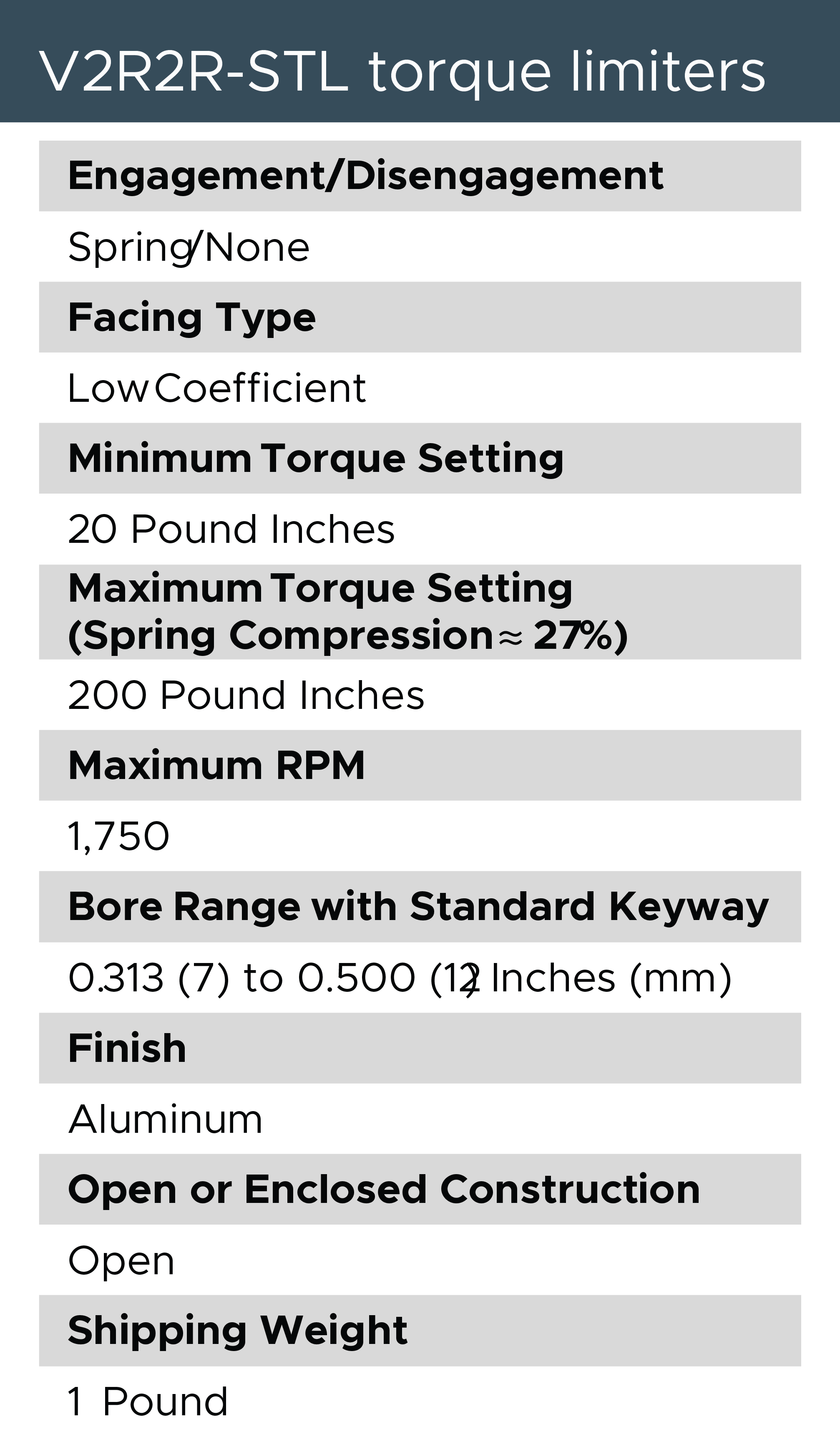

The V2R2R-STL is a mechanical torque limiter with adapter sleeve. The latter necessitates simple but precision installation with a torque wrench and other tools … But these torque limiters usually ship with the specified torque value to within about 10%.

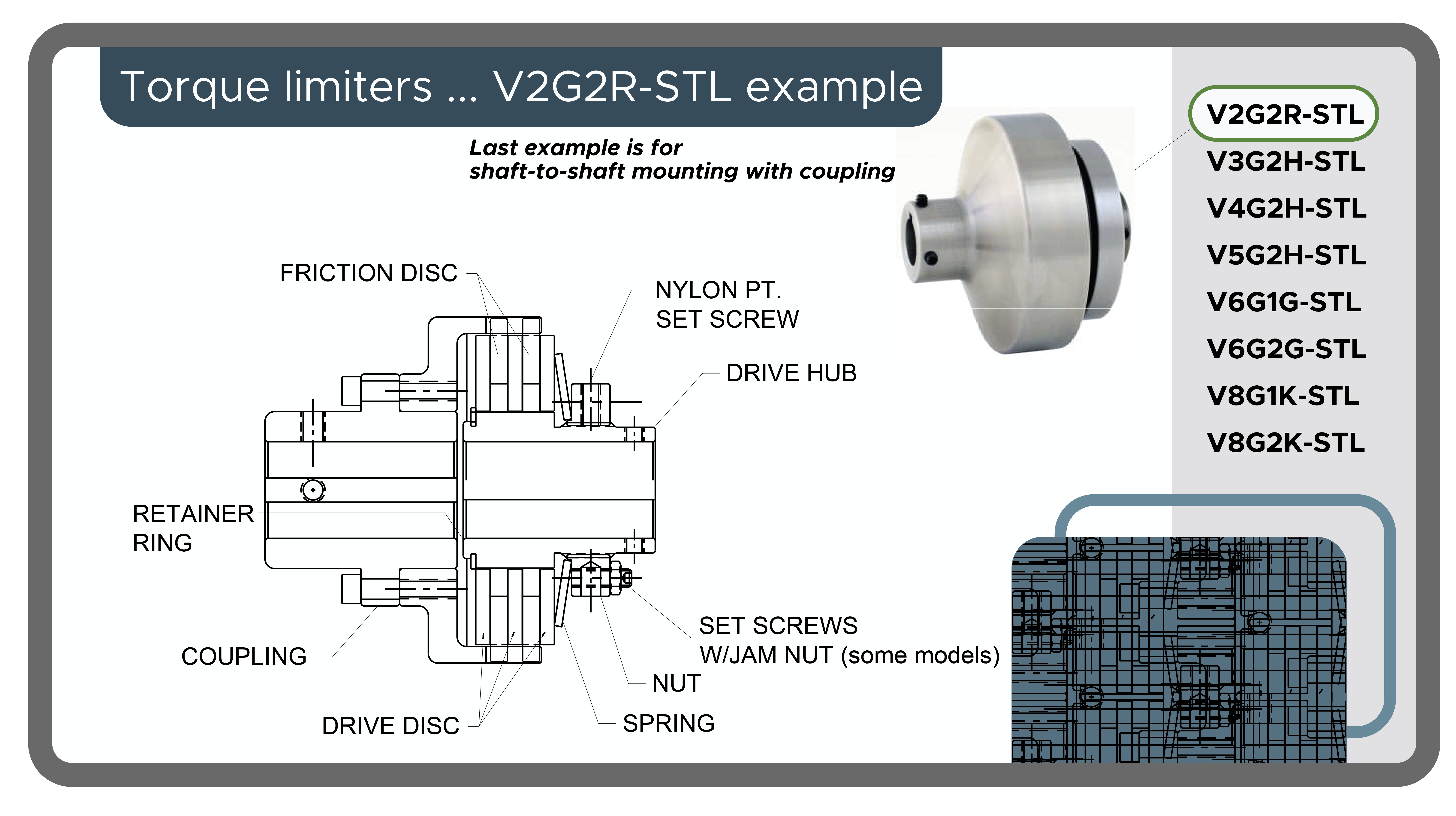

Our third and final sample here is a V2G2R-STL shaft-to-shaft mechanical torque limiter. It’s complete with rigid coupling. This is a spring-engaged unit capable of torque maximums of 20 to 200 lb-in. depending on the setting.

One caveat: All these torque limiters are for momentary events and will continue slipping until the jam or other overload source is cleared. That means designs employing these components must include some way to detect torque overloads.

For more information, visit machiii.com and motioncontroltips.com.

Leave a Reply

You must be logged in to post a comment.