In a recent Design World video with my super-smooth colleague Mike Santora, I got the chance to play with a GA800 ac drive demo from Yaskawa America Inc. This VFD includes network communications, embedded functional safety, and easy-to-use tools (including a smartphone app) for configuration and remote access.

Yaskawa sent us a sample of the VFD unconnected … and another one in a working demo complete with I/O box, HMI, network switch, and Bluetooth connectivity.

Yaskawa GA800 drive physical features

The Yaskawa GA800 comes in an array of models. The sample we got has an IP20 housing for installation inside a cabinet. A NEMA 1 kit is available for standalone installations.

When installed inside a cabinet, the drive can be mounted either with the heatsink internal — or with the heatsink external — for optimal heat management.

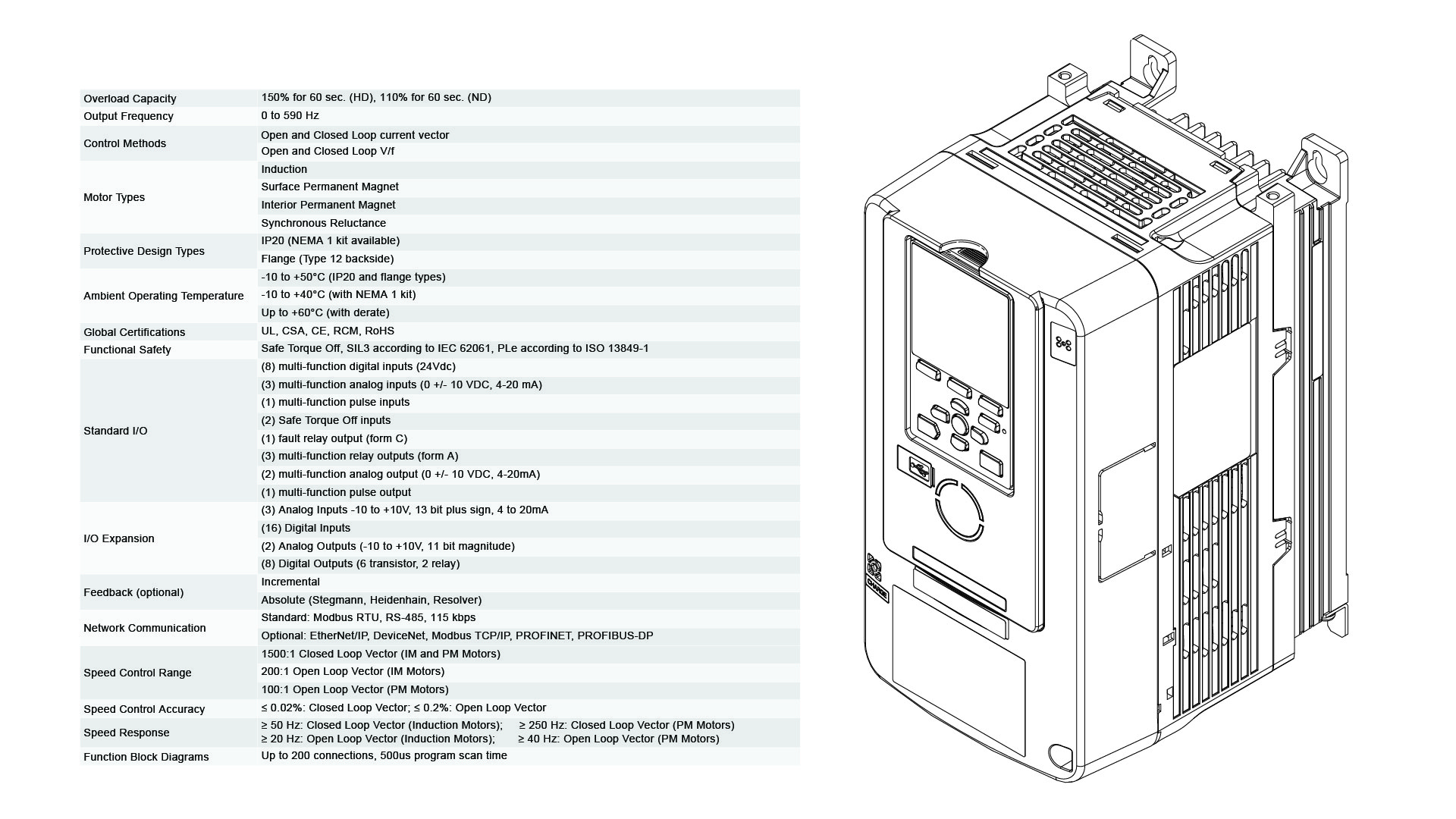

The GA800 controls induction motors as well as permanent-magnet and synchronous reluctance motors. A Smart Power Saver mode reduces energy consumption at reduced speeds and loads for top efficiency.

Top frequency is 590 Hz; normal-duty overload is 110% … heavy-duty overload is 150% … and the drive has an integrated brake transistor through 100 hp.

The drive also includes autotuning functions to optimize motor performance and avoid tripping even under aggressive settings. It provides very good open-loop performance for general-purpose applications … but can also support closed-loop vector control for applications needing quick response and top precision.

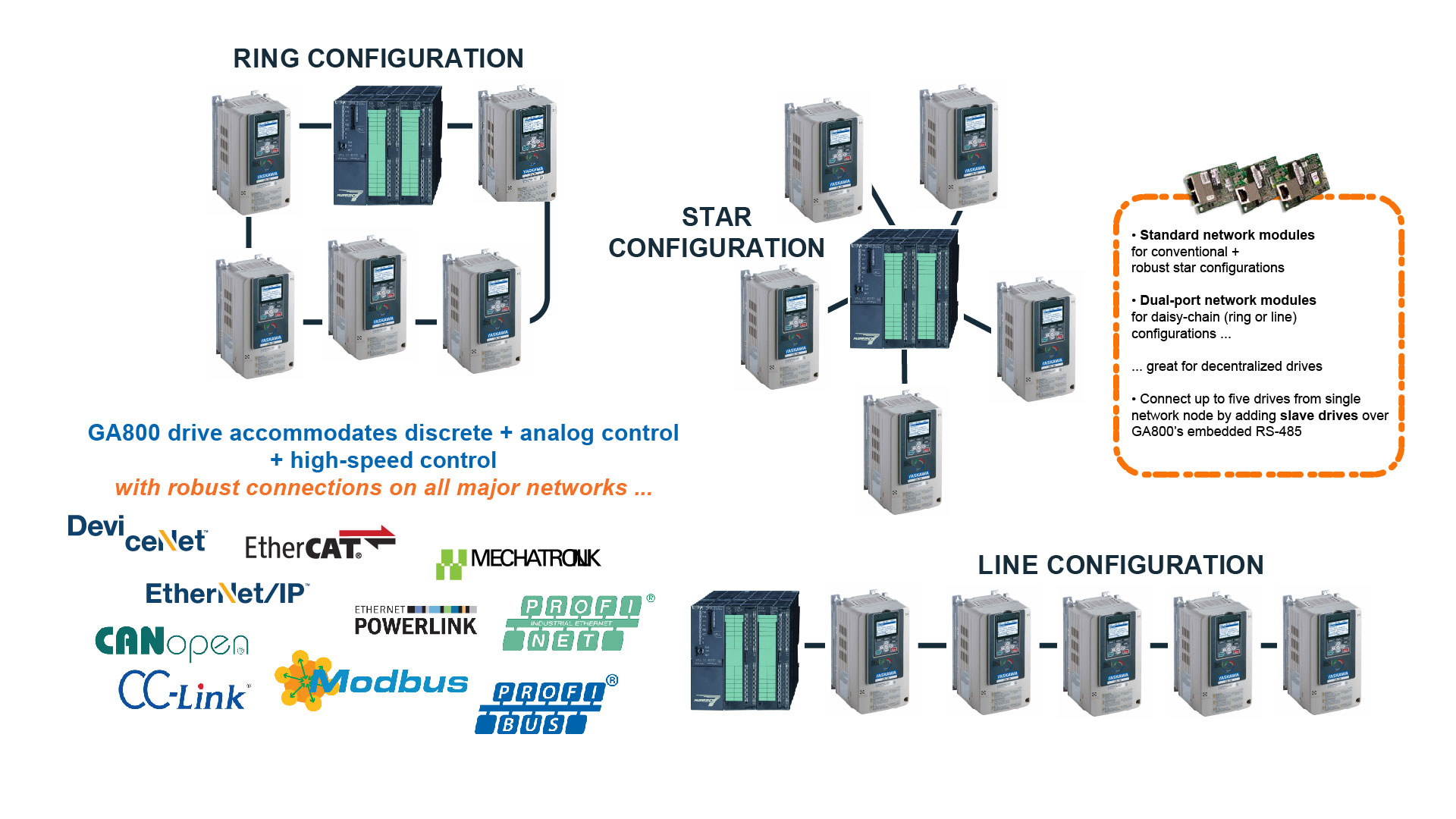

Regarding ways to control the GA800, not only does it support embedded and expandable I/O, but it also supports expansion cards for all major industrial networks including the ability to connect in ring, star, and line configurations. There’s also a removable control terminal board for easy wiring. It takes about 60 seconds to remove the drive face and get the terminal board off.

Standard inputs include RS-485 Modbus RTU; 8 digital, 3 analog, 1 pulse; safe Torque Off; and 24 Vdc auxiliary power.

Standard outputs include 4 digital, 2 analog, 1 pulse, and a 24-Vdc supply for external sensors. Expansion modules are available for additional I/O, encoder feedback, and network cards.

The drive also has euro-style main power connections to allow bare wire or ferrule connections.

Check out this YouTube playlist for details relating to the installation of the GA800 ac drive ⚙️

Yaskawa GA800 drive networking and connectivity

The drive also simplifies connections and networking with other components so common for automated applications.

On the drive face there is a green run LED that indicates when the drive is running; alarm LED; network status LEDs; function keys; a local-slash-remote button to switch between controls for the run command and frequency reference; navigation keys; and run and stop buttons. There’s also a USB Port for mobile-device connections.

A LED Status Ring indicates the drive operation status. A charge LED indicator glows when main power is applied to the drive … and drive information is accessible via a QR code. Through a switch via an Ethernet cable, the drive connects to the same network as a PC or PLC.

This switch and the HMI in the demo we got are from Red Lion — demonstrating how the Yaskawa GA800 drive connects to third-party devices.

Through such HMIs, the drive allows controls, monitoring of drive status, access to any fault logs, drive initialization, I/O control, and more.

A standard feature of the GA800 is Safe Torque Off, which prevents torque production of the connected motor even while main input power remains applied. This minimizes downtime when people enter the mechanical safety zone … increasingly important in settings that employ collaborative robots. It also lets normal operation resume faster.

Yaskawa GA800 drive accepts configuration via Yaskawa’s DriveWizard

Yaskawa’s DriveWizard mobile app is downloadable from the Google Play Store or Apple’s App Store. This app lets engineers setup and operate the drive via a smartphone. The DriveWizard mobile app works with GA800 models having an LCD keypad with Bluetooth connectivity for wireless communication. Android phones can also connect to the drive (through the keypad) via a USB interface — even without main power.

In fact, the DriveWizard app is the mobile version of Yaskawa’s DriveWizard Industrial software. Engineers can use it to backup, store, and retrieve drive settings locally or to a personal Yaskawa Drive Cloud account.

The app’s user-friendly interface lets engineers quickly register, commission, startup, and diagnose the drive.

For more information, visit this deep link detailing the GA 800 on yaskawa.com.

Leave a Reply

You must be logged in to post a comment.