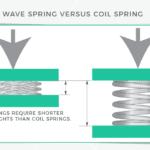

Within mechanical designs, tension, compression, and torsion springs take numerous forms to store and release energy. A wave spring is a type of compression springs made of flat wire. They are called wave springs because they have multiple waves per turn. The flat wire, along with the multiple waves per turn, combine to create the same spring force at reduced work heights compared to round wire coil springs.

Recent technology innovations in manufacturing, have led to applications decreasing in size — so the need for more compact springs has grown. A wave spring’s reduced work height (compared to that of a traditional coil spring) lets engineers shrink the overall height of the spring cavity. This often translates to a smaller assembly and potential weight savings.

Wave springs are designed around a spring force and work height. These requirements are determined by the application. The spring can be configured to accommodate cycling or static operations. A valve is an example of a cycling application. The spring oscillates between two work heights to regulate the valve. A wave spring can also be used in a static application such as preloading a bearing. In the bearing example, the spring is compressed to a work height and remains at that height for the lifetime of the application. This reduces vibration and ultimately prolongs the life of the bearing.

A wave spring is available in an array of materials. The material is dictated by the application environment. When the spring is not exposed to corrosive elements, carbon steel is the standard material used.

Wave springs are available in a range of stainless steels if the spring is in a corrosive environment. For high temperatures environments, an exotic alloy wave spring may be required. Common exotic alloys include, Elgiloy, Hastiloy, and Inconel.

The versatility of the wave spring allows it to be used in a variety of industries — including oil and gas, automotive, medical, and aerospace. Wave springs are used across these industries because they can range in sizes from as small as 0.157 in. (or 4 mm) to 120 in. or 3,000 mm in diameter.

Because wave springs are produced from coiling, manufacturing a custom spring can be an economical solution. Often only a simple set up is required, available with no tooling, to produce a spring that meets unique application requirements.

Leave a Reply

You must be logged in to post a comment.