Wave springs are core to myriad gear, actuator, clutch, and consumer-grade motion assemblies. They are load bearing — included in designs to address play or compensate for dimensional variations. Wave springs apply load in axially — so are specified by working height (and other parameters).

All springs are either for applying load in tension, compression, or torsion. Tension springs work for assemblies where applications rely on a stretched spring to pull the kinematic system bac to some setting. Compression springs work for assemblies where applications rely on a shortened spring to re-expand. Torsion springs work for assemblies needing application of torque.

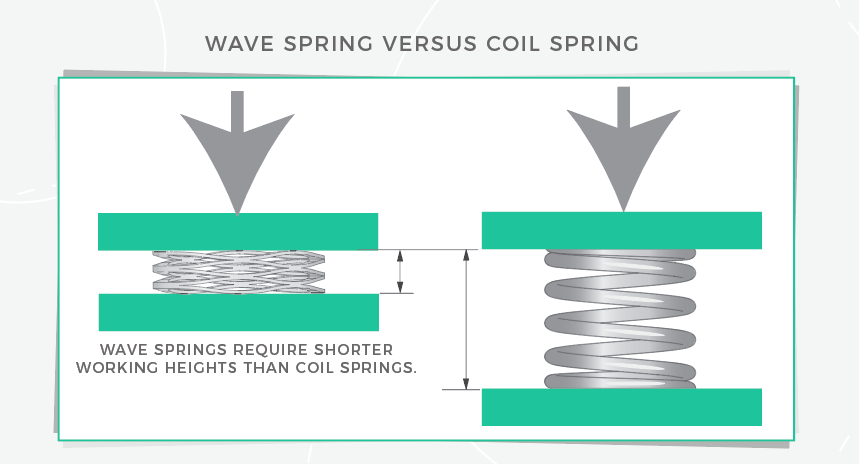

Compression-type wave springs are by far most common. Single-turn wave springs can have overlapping ends to save axial space; nested wave springs deliver higher axial forces; multiple-turn wave springs are up to 50% shorter than a coil spring of otherwise comparable performance. What’s more, multiple-turn wave springs prevent torsional moves during compression — which is an issue with coil springs.

Material science looms large for wave-spring design. Some manufacturers tout the high strength and reliable performance of their springs. Many of these characteristics are quantified in terms of tensile strength, shear strength, modulus of elasticity, and more. The material from which the spring is made as well as the mode of wave-spring manufacture influence many of these values. Case in point: Some edge-wound springs made of flat wire can outperform springs stamped out of sheet metal, as their metal crystallites having long axes tending towards an orientation parallel to the spring’s curvature.

How to select a wave spring?

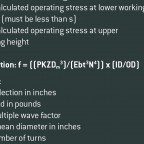

A basic formula helps design engineers specify wave springs and identify whether a design can use a standard spring — or require a custom wave spring. The dominant parameter is load to which the application subjects the wave spring. This load is the axial force the spring must deliver at its work height within the assembly.

Some applications require multiple working heights so have critical loads at two or more wave-spring conditions. It’s often sufficient to use minimum and maximum loads for calculations, especially in motion assemblies requiring compensation for tolerance stackup.

Wave springs install onto shafts or into areas of the assembly machined as working cavities (internal bores). Piloting grooves or other geometry helps the wave spring stays in place. Distance between surfaces inducing load defines axial working cavity — and working spring height. This is where the spring’s material cross-section affects overall design.

More specifically, the factors dictating suitable wave-spring design include application load; bore geometry, shaft, ID, and OD; working height; and spring material to withstand environmental factors. Other general guidelines are that the wave-spring number of turns must be between two and 20; express the number of waves per turn in half-turn increments; minimum radial wall is three times wire thickness; and maximum radial wall is 10 times the wire thickness.

Reconsider working height for a moment: Designs must avoid situations that compress a wave spring to solid. That’s because as a wave spring approaches a height at which it becomes solid (with the various turns contacting or wave turns flattened) loads increase exponentially and even become unpredictable. These loads in turn can induce the spring to take a set or relax. Magnitude of relaxation depends on load and other application conditions. In any case, material deformation wll degrade spring performance.

More specifically, if a spring is going into a static application, ensure that percent stress at working height is less than 100% because springs can take a set or lose length loss under high stress.

If a spring is going into a dynamic application, ensure percent stress at working height is less than 80% because again — springs can take a set if subject to higher stress. If work height per turn is less than twice the wire thickness, the spring operates in a nonlinear range … and actual loads may exceed calculated loads.

Most manufacturers only test standard wave at the loads and work heights specified in literature. Usually they publish work heights that are the lowest recommended for a given spring … though other heights maybe possible. But contact the manufacturer for analysis of spring characteristics at alternate heights. Manufacturers can sometimes help OEMs design wave springs for applications that cannot adhere to normal guidelines.

Wave-spring technology advances to satisfy today’s applications

According to Sanjeev Rivera of Lee Spring, there are some industry moves towards design miniaturization. Wave springs excel here, thanks to the way they deliver a given spring force in significantly reduced space. So designers can reduce finished assemblies’ size and weight through use of wave springs.

Wave springs have also benefitted from new availability of raw materials and end configurations. Design engineers should consider these designs wherever applications are subject to weight or space restrictions. We often advise designers that wave springs in a sense act as stacked wave washers in series configuration — but without any worries about maintaining alignment. That’s because the wave-spring design maintains alignment on its own. Unique wave-spring variations such as nested and interlaced wave springs also exist to incorporate advanced fatigue and load-rating characteristics. Application of these geometries really depends on the assembly at hand.

Leave a Reply

You must be logged in to post a comment.