Let’s face it — when designing a motion control or automation system, engineers don’t immediately think of enclosures and component mounting. They’re instead concerned with selecting the right type of controllers, motors, actuators, feedback, and networking all of these pieces together. Not top of mind (usually) is how a controller will fit inside of an instrument rack and how it will connect with other components.

But simply because mounting accessories may not be top-of-list items doesn’t make them any less important and worthy of consideration than any other piece of a properly functioning automation system.

And so we come to the humble DIN rail. DIN is an acronym for Deutsches Institut für Normung, or the German Institute for Standardization in English. The mounting rail dimensions and specifications were at first standardized by DIN and have since become accepted EN and IEC standards applicable globally. A DIN rail is basically a standard for metallic rails inside of equipment racks onto which are mounted control components such as controllers (PLCs, individual controllers, etc), power supplies, I/O and other types of modules. Most if not all component manufacturers accommodate or supply components that fit on standard DIN rails.

They are typically made of a few different materials, with the most common being galvanized steel. Other materials include copper and aluminum. However, the main way DIN rails are classified is according to rail shape and dimensions. For instance, there are generally considered to be three basic types: the so-called “top hat”, C section and G section.

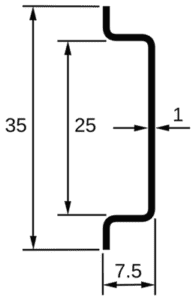

Top hat – The most common is the “top hat” rail, which looks a bit like a top hat in a cross-sectional view. In the U.S. they’re also known as TS 35 rails. The top-to-bottom rail width is 35 mm and lengths can vary. There are two standard depths; 7.5 and 15 mm, with the more common being the 7.5-mm version. There is also a miniature top-hat version with a rail width of 15 mm and a depth of 5.5 mm.

C section – C section rails are 32 mm wide and their cross section is like a C shape. These are older variants of the standard with the top-hat variety being the far more common type. The four common types are C20, C30, C40, and C50, with the number corresponding to the height of the rail in millimeters.

G section – G section rail resembles a “G” in profile, with a deeper recess on one side. This is usually mounted facing down with the smaller recessed side up. G rails are typically used for heavier components such as power supplies.

Leave a Reply

You must be logged in to post a comment.