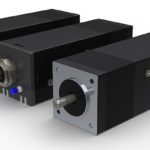

The class of motors known as “smart” motors continue to see a steady increase in use in many industrial applications. A smart motor is essentially a motor that integrates a number of other components together into one physical unit. Common configurations include a motor and drive, but can also consist of integrated encoders and controllers as well as cabling and communication ports.

Aside from the increased processing power and control options that such motors make available, their other powerful feature is the improved connectivity options they offer to designers of complex industrial machinery and motion control systems.

The concept of the “smart” motor goes hand in hand with connectivity. In fact, that’s largely what qualifies a motor as having intelligence; the ability to communicate with other motors and control-system components as well as having some amount of control functionality on-board. This is what makes smart motors with their improved connectivity options central to the IoT and industrial IoT (IIoT).

Some common communication options include serial communication links such as RS232 or RS485 and advanced network topologies for complex motion control tasks. The most common of these are a variety of Ethernet-based protocols such as EtherNet/IP and EtherCAT among others. The increased adoption of Ethernet-based networks in industrial and motion settings is partly what has allowed for the the expansion of the industrial IoT.

EtherNet/IP – EtherNet/IP can provide deterministic, real-time, closed-loop performance while still maintaining compliance with Ethernet standards. Thanks to the ODVA-developed network extensions known as the Common Industrial Protocol (CIP) yielding CIP Motion and CIP Sync (for synchronizing clocks between axes), EtherNet/IP is able to address the need for multi-axis distributed control.

EtherCAT – An Ethernet-based protocol developed by Beckhoff Automation, EtherCAT (Ethernet for Control Automation Technology) is well-suited for synchronized multi-axis motion control applications. It also doesn’t require any additional hardware to synchronize between multiple axes. One difference between EtherCAT and EtherNet/IP is that fewer devices can be connected together via EtherCAT. Plus, it generally is a bit more costlier than EtherNET/IP and also comes with less standardization, making integration somewhat more difficult.

Nevertheless, more companies have been adding EtherCAT support to their offerings. Part of the reason may be the gigabit Ethernet speeds… For instance, a product like EtherCAT G from Beckhoff (describe it) aids in applications such as machine vision cameras, complex motion control systems and measurement equipment operating with high sampling rates.

SERCOS – The Serial Real-time Communications System (SERCOS) protocol is an open high-speed protocol for closed-loop real-time data. There are two transmission types; one being noise-resistant fiber-optic rings (such as SERCOS I and II) or over industrial Ethernet cable as in SERCOS III. The digital bus is used to network motion controllers, drives, and sensors and actuators in a number of different applications.

Since 2017 the SERCOS OPC UA Companion Specification lets designers enable machine-to-machine interoperability and machine integration with cloud-based applications. SERCOS suppliers can now take advantage of the service-oriented architecture of OPC UA.

Leave a Reply

You must be logged in to post a comment.