Now, a production line centered around conveyors from QC Conveyors is helping one medical-device manufacturer boost production of sterile product.

CooperSurgical is a maker of diagnostic and therapeutic medical devices to women’s healthcare providers. Recently the manufacturer turned to QC Conveyors to setup a new production line that maintains the cleanliness required for packaging medical products, but with high throughput in a tight plant footprint.

Engineers from QC Conveyors worked closely with the CooperSurgical team to develop this system. Ultimately the engineers designed an installation that uses several conveyors from QC Conveyors. Then CooperSurgical took the lead to design and build an automation system to make optimal use of the equipment.

“QC Conveyors helped CooperSurgical put together a new overhead conveyor system that moves parts from our molding to the packaging cell — and it also acts as our stock room, using more than 80 feet of straight conveyors,” explained Kevin Hicks, senior manufacturing engineer at CooperSurgical.

One unique design element of the installation is something that QC Conveyors and CooperSurgical devised together — an elevator-type conveyor to move product vertically without taking up floor space. Here, QC Conveyors engineers customized the elevator-type conveyor to take large bins up to an overhead track of conveyors that moves finished and collected product towards shipping while doubling as storage space.

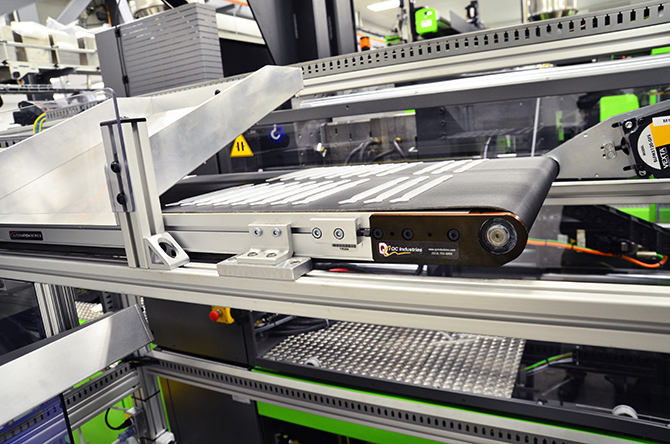

In short, the production facility processes cervical-sampling spatulas. First the sticks are made in a plastic-injection molding machine and pulled out with robot grippers. Then they drop onto a QC Conveyors AS40 conveyor, which moves them to a machine where they’re banded into groups. The banded groups move on a QC Conveyors AS40 cleated conveyor into a bagging machine built by Automated Packaging Systems. This machine bags the sticks and drops them into bins on another QC Conveyors unit.

Once a bin is full, it’s advanced forward onto a custom-built elevator system. This elevator is comprised of two of QC Conveyors 300 Timing Belt conveyors running vertically with an InnerDrive conveyor mounted between them. The InnerDrive advances forward and stops once the bin is completely on it. Then the 300 conveyors move in tandem to raise the InnerDrive conveyor. Finally, it advances forward again to move the bin onto AS65 conveyors that are hung from the ceiling.

Those conveyors run the bins across the building to the clean room, where another elevator works in reverse to move them down to a table where workers pack the spatulas into individual bags with paperwork, instructions, and other items required for pharmaceutical product. They then move out of the cleanroom on an AS40Z conveyor from QC Conveyors, where they’re put into a bin for packing and shipping.

“With the previous conveyor system we used, we’d store the components in our stock room and pick them from there to fill orders,” said Hicks of CooperSurgical. “They were stored in large gaylord, which would take the stock room three hours a day to fill (and keep production moving). The parts in storage took 25 skid locations. In contrast, the new conveyors are our stock room, counter, and picker.”

“QC Conveyors conveyor systems have been working out great. The payback was less than two years,” noted Hicks. In fact, once the project was launched the elevators and conveyor systems took off with minimal adjustments; this says a lot for the design and quality of the QC Conveyors product.

QC Conveyors | qcconveyors.com

Leave a Reply

You must be logged in to post a comment.