In a recent interview with Tom Thiffault of Carlyle Johnson Co., we got some fresh insight into trends in brake and clutch technologies. Here’s what he had to say.

Motion systems in general are evolving thanks to advances in engineering analysis — and demand for custom products to meet tight specifications established by such analysis. For example, a clutch or brake in a flight-control application must have operational characteristics plus be light. Design engineers can no longer accept standard products that only meet some requirements at the expense of others.

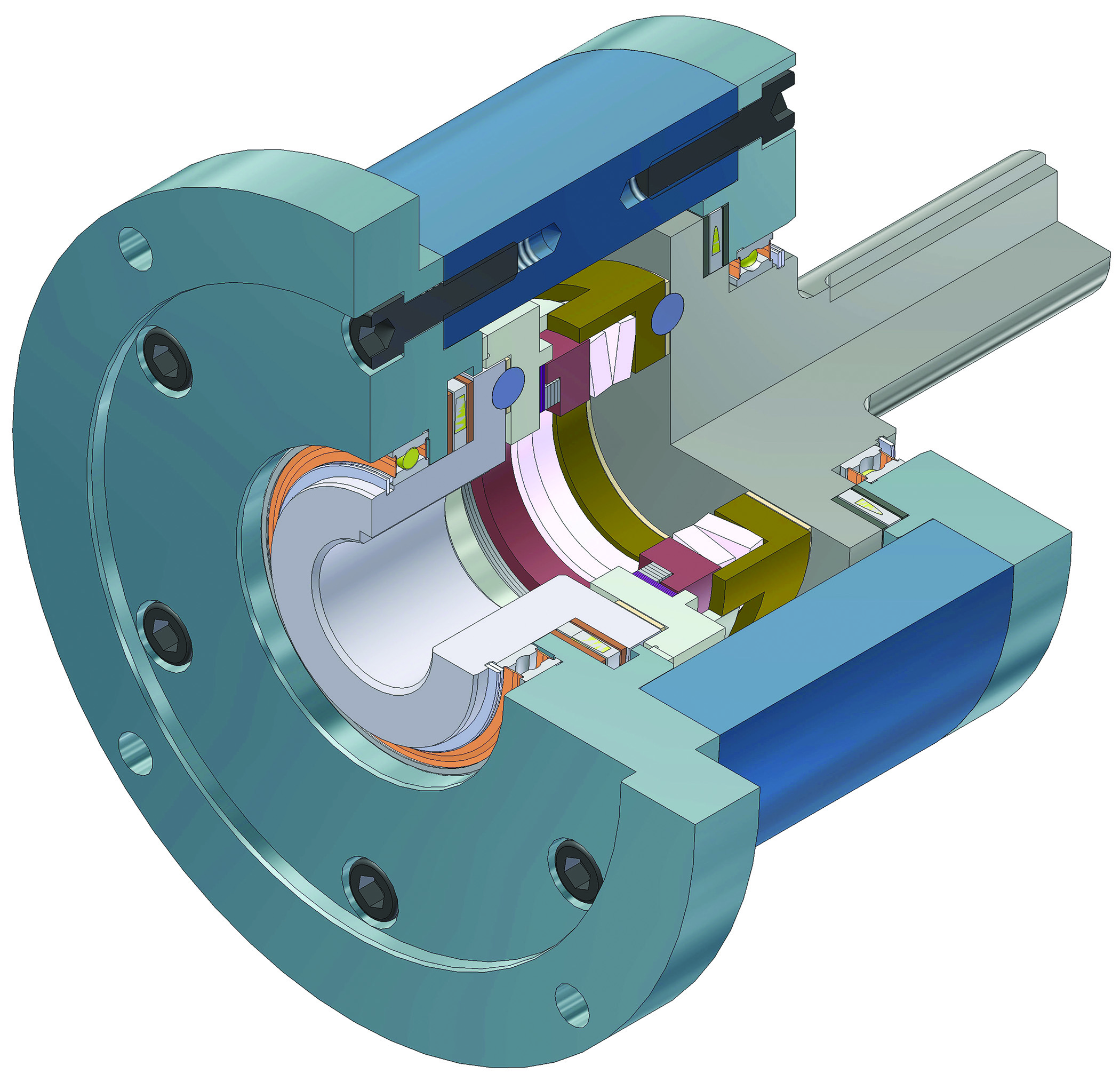

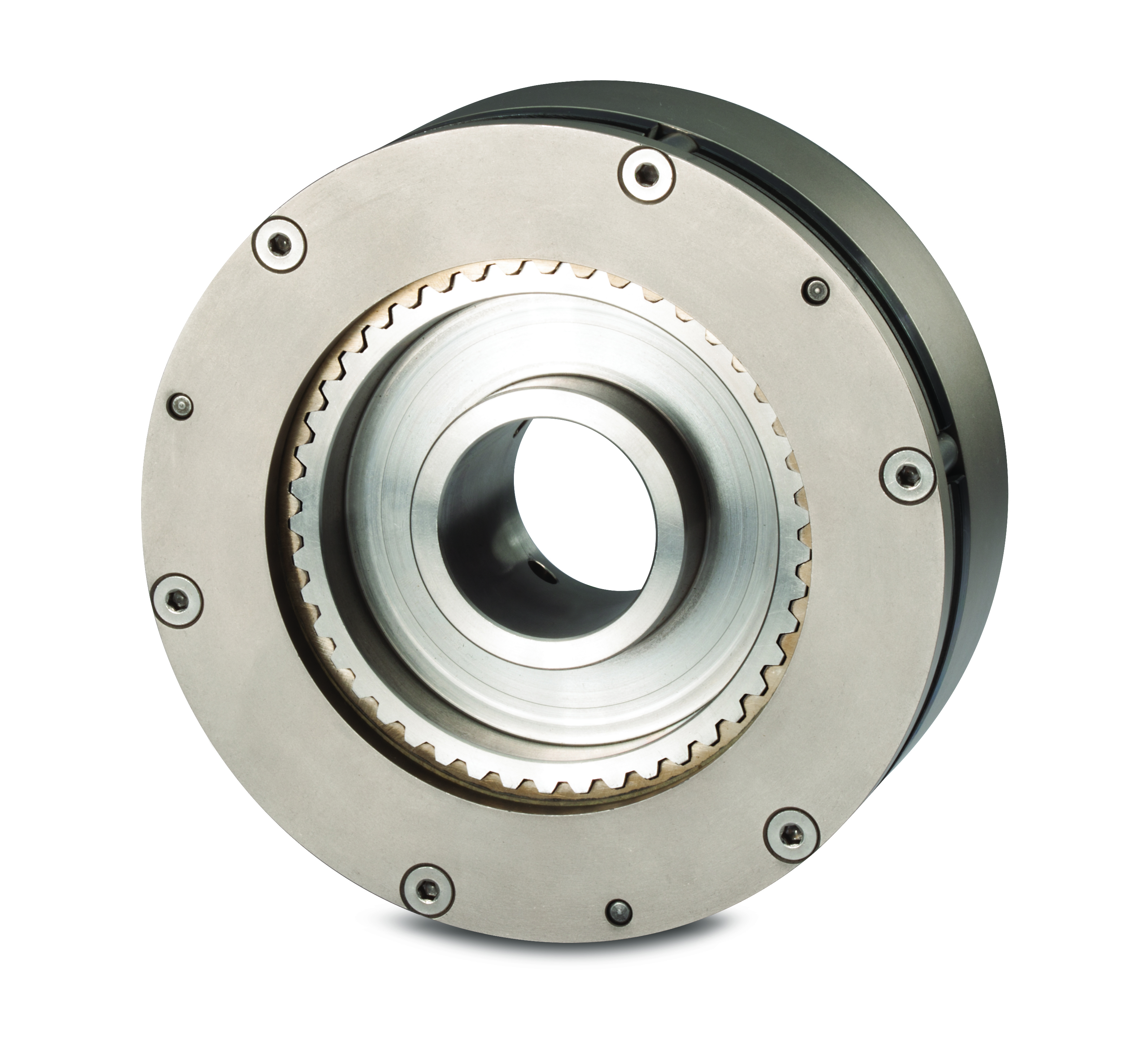

Because brakes usually hold drive position, they must be manually disengaged for the manual system to begin driving. Now, Mechanical Torque Lock (MTL) products from Carlyle Johnson are a new option that automatically transfer motion to secondary drive systems. They include a spring-engaged electromagnetically released clutch for automatic braking when the motor drive is de-energized or if vehicle power is lost. So the MTL can be driven manually to any position. However, when the MTL is released it will hold the shaft from rotating from that specific rotational location … regardless of whether the load on the shaft is trying to drive the shaft clockwise or counterclockwise. Previous options made operators pull or push a pin or mechanism to disengage one drive and engage the other.

Another development is that smart technologies can now monitor equipment functions during operation. Power-transmission manufacturers have developed sensors to gather this information — including speed, temperature, motion, and vibration. So now analysis of data serves to predict failures of specific components.

Case in point: Smart clutches and brakes can tell controls if they’re on or off — and if they are worn and by how much.

Some of this data overlaps with sensors monitoring other system features; with ongoing review for trend analysis, today’s systems can use these parallel data streams to predict component failures and establish typical rates so operators can schedule maintenance instead of risking unplanned downtime. Here, cloud computing is spurring more review and data sharing at multiple sites as well.

Changes in motion and power-transmission design

Clutch and brake suppliers assume more drive-design responsibilities than ever. What’s more, engineers graduating college today have analytical skills to develop extremely specific requirements — and expect products to meet these parameters. So today’s product catalogs list basic product offerings from manufacturers, but special products are increasingly required. That’s why most power-transmission component suppliers today are adapting their engineering knowledge and manufacturing to produce customized products with short lead times.

Benefits and challenges of increased automation

Today, automation only works when it’s flexible — but flexible operations demand that plant operators perform advanced operations analysis to keep factory floors running. So operators traditionally just worked specific machines, today they must analyze the interaction of components to be manufactured as they move through the factory floor. That means operators must also review holistic machine operations and maintenance requirements in detail …including the time required for all tasks.

Connect with Carlyle Johnson online at cjmco.com.

Leave a Reply

You must be logged in to post a comment.