An integral horsepower gearmotor is any motor with a horsepower of 1 and above, as opposed to fractional horsepower motors that are less than 1 hp. The design considerations for integral horsepower motors are going to be fairly similar to fractional horsepower motors because the same types of parameters are important. So for instance, torque and speed matter in all cases.

However, there are a few other considerations that are just as important:

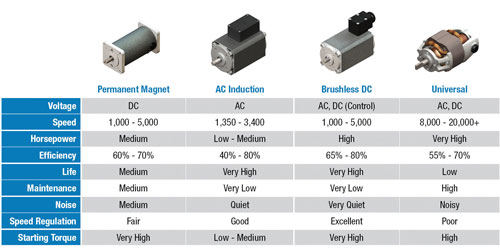

- Motor type – ac or dc, brushed or brushless, permanent magnet. Often times the application will determine which motor is best suited for that particular application. In general, brushless dc gearmotors have really good speed regulation properties, so they’re usually preferred in applications requiring tight variable speed control. However, ac gearmotor have gotten better at speed control and they are now competitive with many dc gearmotors. On the other hand, ac gearmotors generally require less maintenance.

- Gear type – the application demands can help determine the best gear type. Is efficiency the most important parameter? Torque? For instance, planetary gears have high power density and are more compact than other arrangements. They also tend to cost more than other gear types. On the other hand, worm gears are prevalent in many gearmotors, especially right-angle gearmotors, but their efficiency ratings are lower than other gear types.

- Other factors – these include environmental factors such as temperature, IP rating for washdown or debris or spray etc., mounting configurations, lubrication needs, the type of output shaft needed, among others.

For more on gearmotor selection, check out How to Select a Gearmotor in Four Simple Steps.

Leave a Reply

You must be logged in to post a comment.