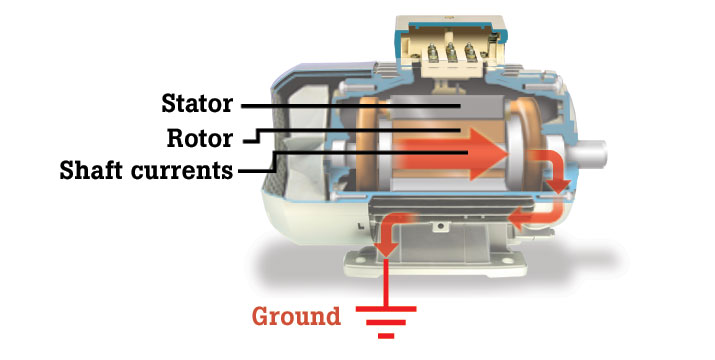

Variable frequency drives convert AC input voltage to DC, and then back to pulse-width-modulated AC voltage with variable frequency. These AC voltage pulses are controlled by insulated gate bipolar transistors (IGBTs). IGBTs have a fast switching time (also referred to as “rise time” or “dv/dt”—rate of change of voltage over time), which reduces energy losses and allows the drive to use a higher carrier frequency for sending output voltage pulses to the motor. But the downside of their fast switching time is that it creates parasitic, or unwanted, capacitance between the motor’s stator and rotor. This parasitic capacitance induces a voltage—referred to as “common mode voltage”—on the motor shaft.

Image credit: Fluke Inc.

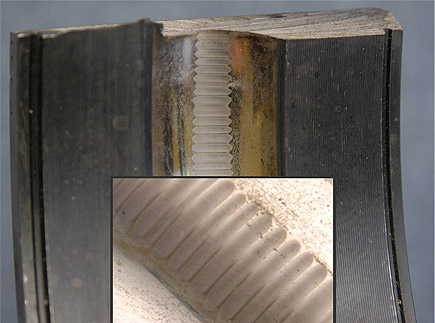

As this voltage accumulates on the motor shaft, the bearing lubrication acts as an insulator, but only up to a certain point. When the voltage exceeds the dielectric strength of the lubrication, it discharges through the motor bearing (i.e. the path of least resistance) to ground. The discharged current has enough energy to pit the balls and raceways of the bearing, through a process known as electric discharge machining (EDM). As these pits accumulate, they create a frosted effect and eventually result in evenly spaced grooves—much like a washboard—in the bearing raceway. This grooved pattern is referred to as fluting.

Dielectric strength is the strength of a material as an insulator. In other words, a material’s dielectric strength is the amount of voltage it can withstand before losing its insulating properties.

Image credit: Electro Static Technology

The first sign of bearing damage is audible noise, due to the bearing balls traveling over the pitted and frosted areas. But when noise occurs, the damage has usually become substantial enough that failure is imminent. By some accounts, electrical damage (damage caused by electric discharge machining) is the most common cause of failure for AC motors driven by VFDs.

There’s no definitive way to predict whether, or when, bearing currents will occur. But there are several methods that can be used to protect the motor bearings from fluting damage and eventual failure. These include:

- using shielded cables

- grounding the motor shaft

- using grease that conducts motor shaft currents to ground

- using insulated bearings

- installing a Faraday shield (conductive material between the rotor and stator)

- installing a dv/dt filter between the drive and the motor.

Leave a Reply

You must be logged in to post a comment.