Demand for motion designs offering simplicity has touched conveyor applications in several ways. Recently we asked Kate Nadeau, engineer with mk North America, about this and other trends in material handling. Here’s what she had to say.

We’re satisfying market demands (including those for turnkey solutions) with a variety of standard conveyors as well as custom-designed (engineered) solutions that are fully assembled and tested prior to shipping. We’re also offering more in-house services to support these customized solutions. We’ve added engineering-department staff and have a new sales and application engineer for the concept and quoting phase. For skilled labor on the assembly floor, we’ve hired and promoted from within. We also work with integrators nationally for integration and installation services … as well as several local motion and control-design professionals for applications that warrant it. We understand and value our integrator customers … and know sometimes they too need suppliers to assume some of the integration work. We believe in working with end users and integrators large and small, knowing designs are never one-size-fits-all.

When asked about challenging industries and what conveyor designs are unlike anything done before, here’s what Nadeau had to say.

It’s impossible to say which industry is most challenging from the motion-design point of view, as each has unique needs. In addition, some of what we do is build reorders of jobs, while elsewhere we’re designing and delivering conveyors that were impossible 10 years ago.

We’ve done defense projects that were highly challenging because of their needing explosion-proof designs.

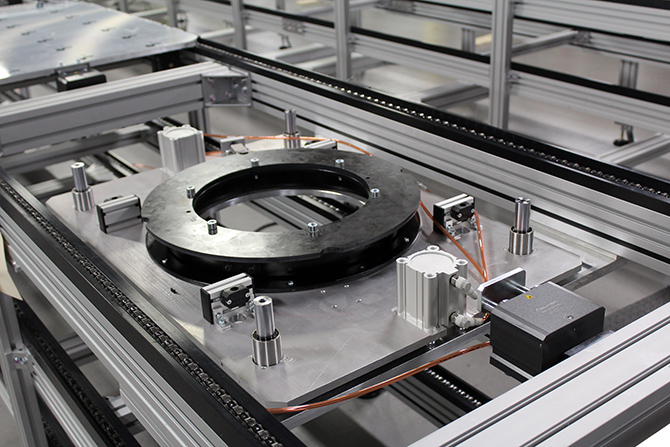

We’ve also done several automotive projects — challenging because their pallets and loads exceeded maximum values for our VersaMove Ultra system (of 1,200 x 1,200 mm and 700 lb per pallet) but they still needed high throughput. This made for the unique challenge of needing to move and control large and heavy pallets both accurately and quickly.

One last example: We’ve done projects in the food industry that were highly complex due to their many concurrent and complex processes that had to happen quickly — combined with the need for the entire solution (including controls) to be food-safe and washdown compliant.

Here’s what Nadeau had to say about the topic of online configuration tools and software.

Clearly these tools have been around for a long while, and they are not going away. While we have a tool for designing and pricing standard belt conveyors online, we’re also considering new and innovative ways to bring more complex conveyor and pallet-handling systems directly to the engineer’s screen. Oftentimes we see engineers more interested in obtaining a model of a possible solution before worrying about the cost associated with it. While cost can often be a deciding factor, it’s by no means the only factor — and it must work with the design software.

Leave a Reply

You must be logged in to post a comment.