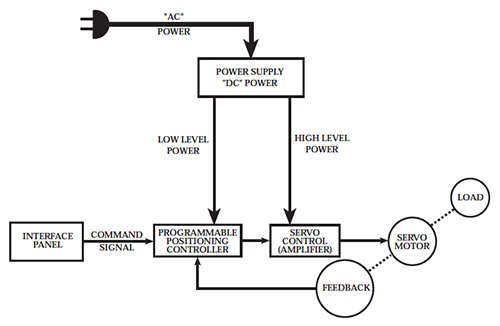

A servo system is one in which the system’s error (in position, speed, or torque) is corrected through the use of a feedback device that compares the system’s actual performance with its commanded performance. What makes a motor a servo motor, then, has less to do with its construction and operation, and more to do with whether it incorporates or reads feedback in a closed-loop system.

Image credit: Baldor Electric Company

So what type of motors can be used in servo systems? That’s not an easy question to answer, since there are many ways to categorize motors and manufacturers often use different terminology to describe the same type of motor. This makes deciphering motor classifications a highly confusing endeavor. To help you cut through the confusion, below is a guide to motor terminology and a brief explanation of which types are most commonly used in servo systems.

There are three main ways to classify motors: by their current—AC or DC; by the way in which they achieve commutation—brushless or brushed; and by the speed of their rotating field (rotor)—synchronous or asynchronous.

AC vs DC

The most basic classification of a motor is whether it is an AC or a DC motor, based on the type of current used. From a performance standpoint, the primary difference between AC and DC motors is in the ability to control their speed. In a DC motor, speed is directly proportional to the supply voltage (given constant load, or torque, on the motor). AC motor speed is determined by the frequency of the applied voltage and the number of magnetic poles.

While both AC and DC motors can be used in servo systems, AC motors can withstand higher current and are more commonly used in industrial servo applications.

Brushed vs Brushless

When discussing DC motors, the next point of differentiation is whether the motor is commutated mechanically, with brushes, or electronically, without brushes. Brushed motors are generally less expensive and simpler to operate, while brushless designs are more reliable, have higher efficiency, and are less noisy.

Brushed DC motors are further sub-divided according to the construction of their stators: series-wound, shunt-wound, compound-wound, or permanent magnet. While the majority of motors used in servo systems are brushless designs, brushed permanent magnet DC motors are sometimes employed as servo motors for their simplicity and low cost. The most common type of brushed DC motor used in servo applications is the permanent magnet DC (PMDC) motor.

Brushless DC motors replace the physical brushes and commutator with an electronic means of achieving commutation, typically through the use of Hall effect sensors or an encoder. Brushless DC (BLDC) motors are also used in servo systems.

AC motors are generally brushless, although there are some designs—such as the universal motor, which can run on either AC or DC power—that do have brushes and are mechanically commutated. Terminology for brushless AC (BLAC) motors can be quite confusing, as they are also referred to as permanent magnet AC (PMAC) motors or permanent magnet synchronous motors (PMSM). Which brings us to the next type of classification…

Synchronous vs Asynchronous

While DC motors are generally categorized as brushed or brushless, AC motors are more frequently differentiated by the speed of their rotating field— i.e. synchronous or asynchronous. Recall from the AC-DC discussion that in an AC motor, speed is determined by the frequency of the supply voltage and the number of magnetic poles. This speed is referred to as the synchronous speed. In a synchronous motor, the rotor rotates at the same speed as the stator’s rotating magnetic field. In an asynchronous motor, normally referred to as an induction motor, the rotor rotates at a speed slower than the stator’s rotating magnetic field.

When induction motors are paired with variable frequency drives, they can achieve speed control and performance similar to servo motors, although they typically don’t incorporate feedback, and therefore, are not true servo devices.

Image credit: Kollmorgen

Brushless AC (BLAC, aka PMSM or PMAC) and brushless DC (BLDC) motors are synchronous, and both types are frequently used as servo motors. In fact, some of the most common high-performance industrial servo motors are 3-phase, synchronous, brushless AC motors.

Keep in mind that there are always exceptions, especially with regard to motor nomenclature. You may (and likely will) find resources with motor terminology that differs from this post, or even new terms not covered here. Just remember that the key to whether a motor can be considered a servo motor, is whether it is used in a closed-loop system with feedback.

Leave a Reply

You must be logged in to post a comment.