In accordance with recent changes in motor efficiency laws, it’s now mandatory that continuous duty motors for integral gearmotors be Premium Efficient. It’s important to recognize that this requirement only applies to continuous duty motors. Motors rated for intermittent operation (for non-continuous applications) are not required to be Premium Efficient. Premium Efficient motors have more rotating mass (or inertia) and this increased inertia takes energy to start and stop. In fact, in many dynamic or high cycling applications, a Premium Efficient motor can actually consume more electrical energy than a low inertia, lower efficiency design.

The rated motor efficiency in itself doesn’t tell the whole story about energy consumption. The correct perspective for energy savings is to focus on the consumed energy for a whole system and not the motor rated efficiency alone. A higher rated motor efficiency does not ensure lower energy usage in an actual application.

Continuous vs. intermittent duty

The classification of a motor as either continuous or intermittent duty revolves around the idea of duty cycle. That is, how long the motor is on and off. So the basic decision for determining continuous vs. intermittent duty is fairly straightforward. If the motor is switched on and runs continuously then the motor should be rated for continuous duty. If the motor is switched on for a short time or has a cyclic operation, then the motor can be rated intermittent operation and the motor has no efficiency requirement. As a rule of thumb, if the motor is running more than one hour continuously with no switching on or off during that time, then, in general, the application is continuous and a Premium Efficient continuous duty motor is required. If the motor runs for less than an hour continuously, then the application can be considered intermittent.

One reason this is so important is that if the wrong motor is selected (intermittent instead of continuous, for instance), the risk is that the motor could overheat, damaging the motor and/or other devices.

Some of the most common examples of intermittent applications include packaging equipment, metering pumps, palletizers and winders and coilers. Typical continuous applications range from bulk material handling conveyors to continuous flow pumps and continuous mixers.

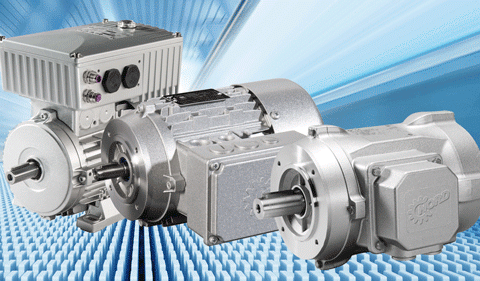

Information supplied by NORD DRIVESYSTEMS

Leave a Reply

You must be logged in to post a comment.