There are a number of ways in which piezo ceramics can be used to create linear motion, providing any combination of high speed, long travel, and high force. Two common types are linear stepper and linear ultrasonic piezo motors. Both use the inverse piezoelectric effect to activate a rod or pusher and create linear motion, but the way in which they employ and harness motion from piezo elements differs.

Image credit: Bruker Corporation

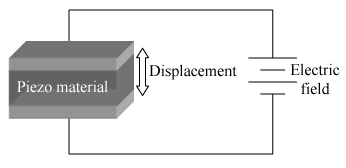

The piezoelectric effect is the conversion of applied mechanical force to internal electrical energy. The inverse (aka reverse or transverse) piezoelectric effect converts applied electrical energy into internal mechanical strain.

Linear stepper piezo motor function

Linear stepper motors are based on the coordinated motion of several piezo elements that are mounted in a row and act as pairs of “legs.” When an electrical charge is applied, the legs experience two motions: extension/retraction and sideways bending.

To generate linear motion, one pair of legs “grips” a longitudinal rod via friction, moving it forward as the legs extend and bend. When the first pair of legs releases, the next pair takes over. The legs of linear stepper motors move only a few microns at a time, but they run at hundreds to thousands of hertz to produce continuous linear motion.

Image credit: MICROMO

Linear ultrasonic piezo motor function

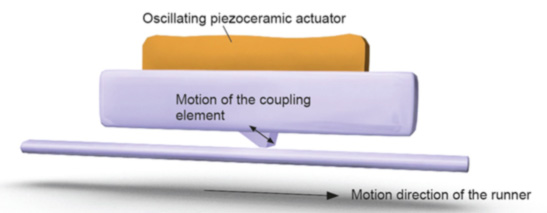

Ultrasonic piezo motors use a single piezoelectric plate. When an electric charge is applied, the plate is excited at its resonance frequency, causing it to oscillate. These oscillations, in turn, produce ultrasonic waves in the piezoelectric plate.

A coupling, or pusher, is attached to the plate and preloaded against a longitudinal rod (also referred to as a runner). The ultrasonic waves cause the plate to expand and contract in an elliptical manner, which enables the coupling to advance the rod forward, producing useful linear motion.

Image credit: Physik Instrumente GmbH

Performance and applications

While both linear stepper and linear ultrasonic piezo motors generate motion by advancing a longitudinal rod, their operating principles give them different performance characteristics. Linear stepper motors can achieve picometer-level resolution, while resolution for ultrasonic versions is typically in the 50 to 80 nm range. But linear ultrasonic motors can achieve much higher speeds – 500 mm/s to 1 m/s – than linear stepper motors, which typically max out around 15 mm/s. Both versions are capable of unlimited travel, but the length of the drive rod determines the stroke. For both stepper and ultrasonic versions, maximum travel is generally 100 to 150 mm.

Linear stepper piezo motors can generate both push/pull and holding (power-off) forces in the range of 10 N, while linear ultrasonic piezo motors are typically limited to 3 to 4 N push/pull and 2 to 3 N holding force. Both versions are self-locking and can hold their rated load in power-off conditions without generating heat.

Linear ultrasonic piezo motors are commonly used in camera autofocus mechanisms, as well as in imaging, scanning, and metrology devices. Linear stepper piezo motors are often used to drive linear stages and in semiconductor lithography equipment.

Feature image credit: MICROMO

Leave a Reply

You must be logged in to post a comment.