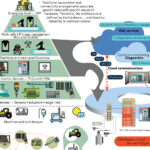

The Festo Power Up initiative for food and beverage machine builders aims to spur the efficient adoption of electric automation and in the process support the development of the next generation of compact, flexible, energy efficient, and data-rich machines.

Three pillars support the initiative. Machine builders now have the option of a Festo one-stop-shop of readily available, high quality, and cost competitive electric automation components. Festo’s design and commissioning tools reduce engineering overhead and help bring products to market faster. Festo recently introduced a remote and decentralized I/O platform that lowers integration cost and boosts the ability of original equipment manufacturers (OEMs) to add capabilities easily and cost effectively to a machine or cell. Taken together, these three (products, productivity tools, and automation platform – can transform the food and beverage machine builder’s business.

“Festo innovations open the door for food and beverage OEMs to innovate solutions through electric automation while improving internal efficiencies,” said Tim Sharkey, Sales Director Electric Automation, Festo North America. “New machine capabilities, faster time to market, and lower internal costs all lead to greater competitiveness.”

Sharkey said that Festo used 50 years of knowledge in simple motion, based on pneumatics, combined with over two decades of research and development in remote I/O and control, and applied this expertise to today’s drive toward electric automation and greater machine flexibility.

A one-stop-shop for electric automation products

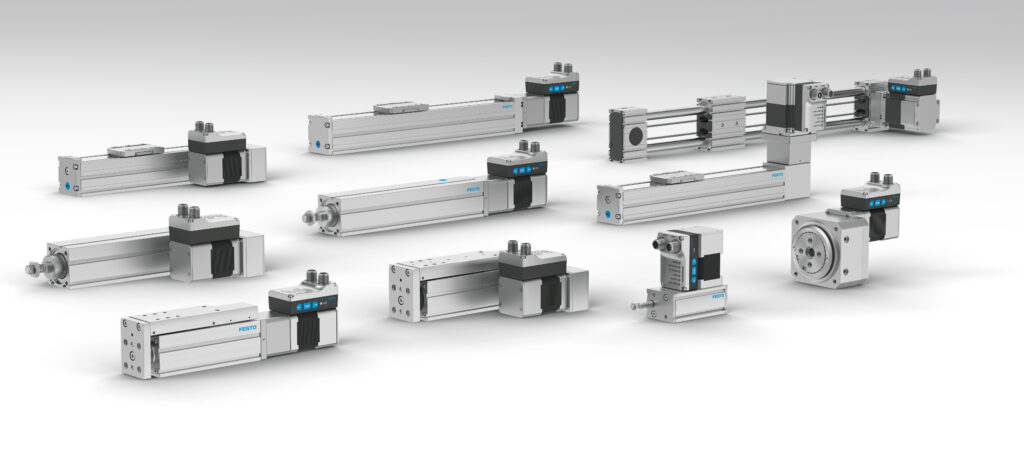

For more than a decade, Festo has expanded its electric automation portfolio. Today Festo offers the Simplified Motion Series of low cost linear and rotary axes with integrated drive, motor, and IO-Link as well as:

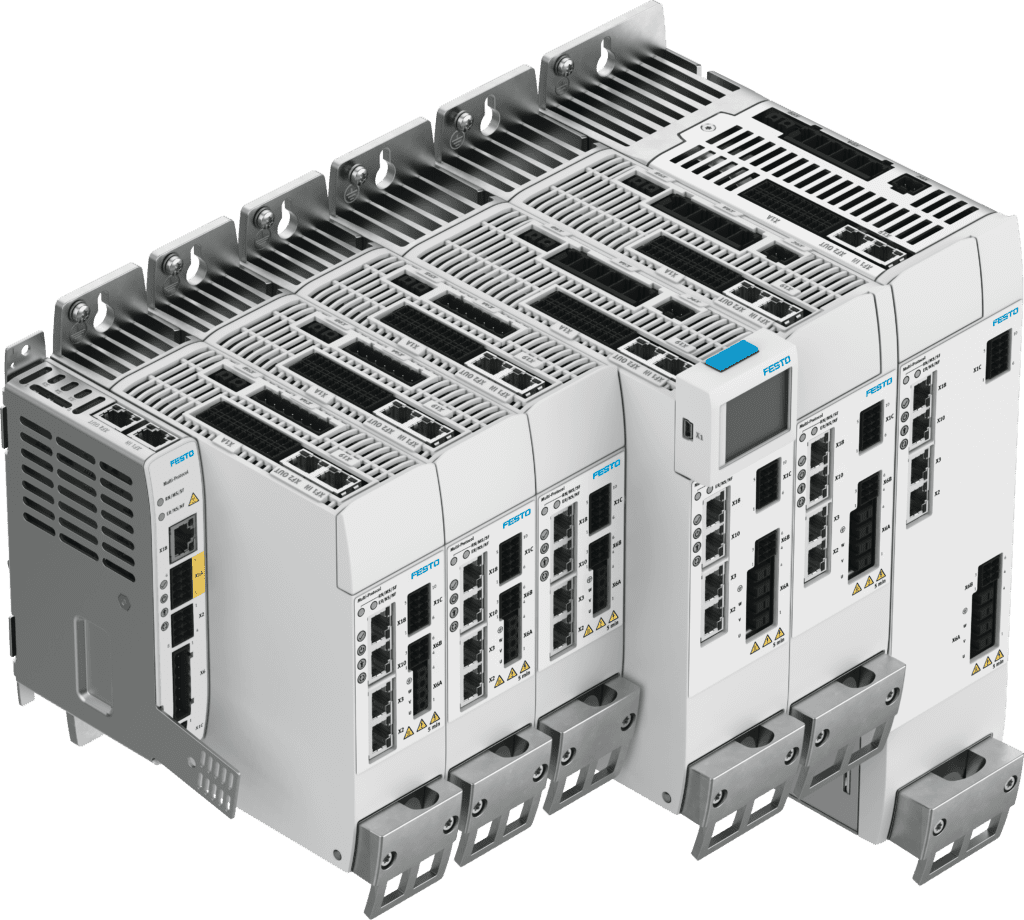

- Servo drives and motors, including the new in-stock multi-protocol CMMT-MP servo drives

- I/O systems and controllers

- Handling systems that are pre-assembled and tested

- Mechanical systems

- Spindle and toothed belt axes and mini slides

- Ball screw linear actuators

- Cantilever linear actuators

- Parallel grippers.

Festo electric automation (both mechanical and electronic components) interoperate, assemble quickly without difficulty, and lower the risk associated with integration.

Faster design and commissioning

The online Festo Electric Motion Sizing and Handling Guide Online productivity tools allow one, two, and three axis electric automation systems to be designed and ordered in minutes, not hours or days. Design engineers simply enter application parameters (no programming is required). These tools give the designer several solutions to choose from – options in terms of performance and cost. Components are guaranteed to be readily available and interoperable, a plus for businesses tired of supply chain delays.

At the end of a minutes long design session, the engineer receives a quote, shipping date, parts list, and 2D and 3D CAD files. Having immediate access to CAD files means that the machine builder can continue designing while the electric automation system is being readied for shipment.

Following an Electric Motion Sizing and Handling Guide Online session, the commissioning files are automatically compiled and ready for download to the PC-based Festo Automation Suite, a single tool for setting up a drive package from mechanical system to controller. Having the commissioning file saves an enormous amount of time and reduces the possibility of commission errors.

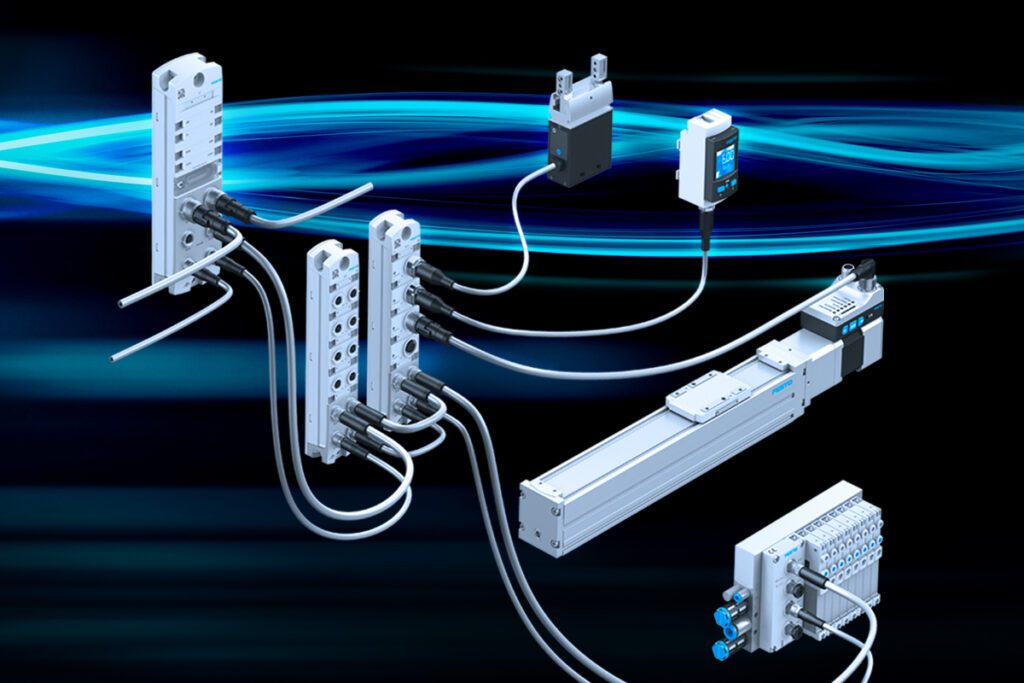

The new Festo Automation Platform remote and decentralized I/O

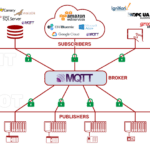

Festo’s revolutionary Automation Platform enables all CPX-AP-A remote I/O and CPX-AP-I decentralized I/O to be integrated by the control engineers as a single integration point under one IP address. This makes integration with the PLC simpler and since all I/O is under a single IP address, it’s possible for the machine builder to use a smaller, less costly PLC.

The Festo automation platform is compatible with the EtherNET/IP, EtherCAT, PROFIBUS, and Modbus communication protocols. OEMs building similar machines but using customer preferred PLC simply apply a protocol specific AP bus interface module. I/O can remain the same or can be easily changed, all under a single integration point and one IP address. The AP platform uses IO-Link masters to incorporate third-party devices within a machine or cell.

Power Up gives engineers, maintenance personnel, and technicians just one unified system to learn, not many. Power Up lowers inventory requirements. Using a single supplier’s products simplifies field support. Furthermore, Festo assigns a unique part number to each electric automation assembly and that number is linked to a complete parts list for easy reference and reordering.

For more information on the advantages of working within the Festo ecosystem ‒ the ecosystem that leads to less engineering overhead, fast time to market, and seamless connectivity, visit www.festo.com.

Leave a Reply

You must be logged in to post a comment.