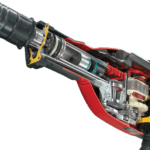

Gearmotors are often used in position control applications. A prime example would be in packaging or material handling where a load needs to be picked up or placed at a specified location, or applications with more precise requirements such as micro-positioning in high-precision manufacturing or dispensing.

Application requirements will dictate the level of accuracy needed from the gearmotor. For instance, low-accuracy applications are ones where the position can be “good enough,” such as a robotic arm placing boxes on pallets. On the other hand, high-accuracy positioning may require accuracy in thousands of an inch or even at the micron level.

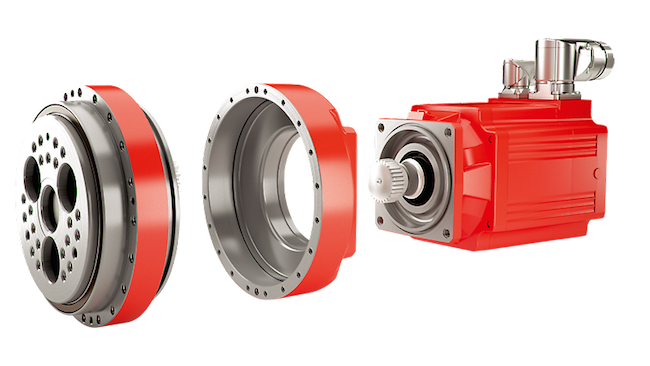

In reality, just about any type of gearmotor can be used for position control. The real question is how accurate does the positioning have to be, in which case the focus shifts to the type of gears in the gearmotor.

And why is gearing important? One of the main culprits for inaccuracy in gearmotor positioning is backlash in the gears. So, if positioning accuracy is a key variable in your application, you’ll want to make sure that you choose a gearmotor with minimal backlash in the gearing. Manufacturers have several methods for minimizing backlash in gears including pre-loading and using gears that are designed to minimize or eliminate backlash from the start.

Leave a Reply

You must be logged in to post a comment.