Machine vibration is a normal, and typically unavoidable, result of moving and rotating parts, often caused by standard manufacturing and assembly tolerances that lead to clearances between mating parts or imbalances in rotating parts. And while routine machine wear can cause vibration to increase over time, when a machine experiences a significant or sudden increase or change in vibration, this can be an indicator that something is wrong and the machine or its components are being subjected to increased forces, loss of stiffness, and premature wear.

Image credit: Prueftechnik

Although it’s not difficult to detect when vibration is approaching (or has reached) detrimental levels, pinpointing its causes can be challenging, since numerous components and operating factors contribute to a machine’s vibration. But an analysis of the vibration’s frequency and amplitude can help engineers and technicians root out the causes of worrisome vibration and determine its severity.

Vibration frequency

Frequency indicates the number of times an object oscillates, or vibrates, per unit of time and is often expressed in either cycles per second (referred to as Hertz, Hz) or cycles per minute (CPM). Frequency is probably the most fundamental parameter in machine vibration analysis. It is especially useful for narrowing down the potential causes of vibration, since every part vibrates at a distinct frequency or frequency range.

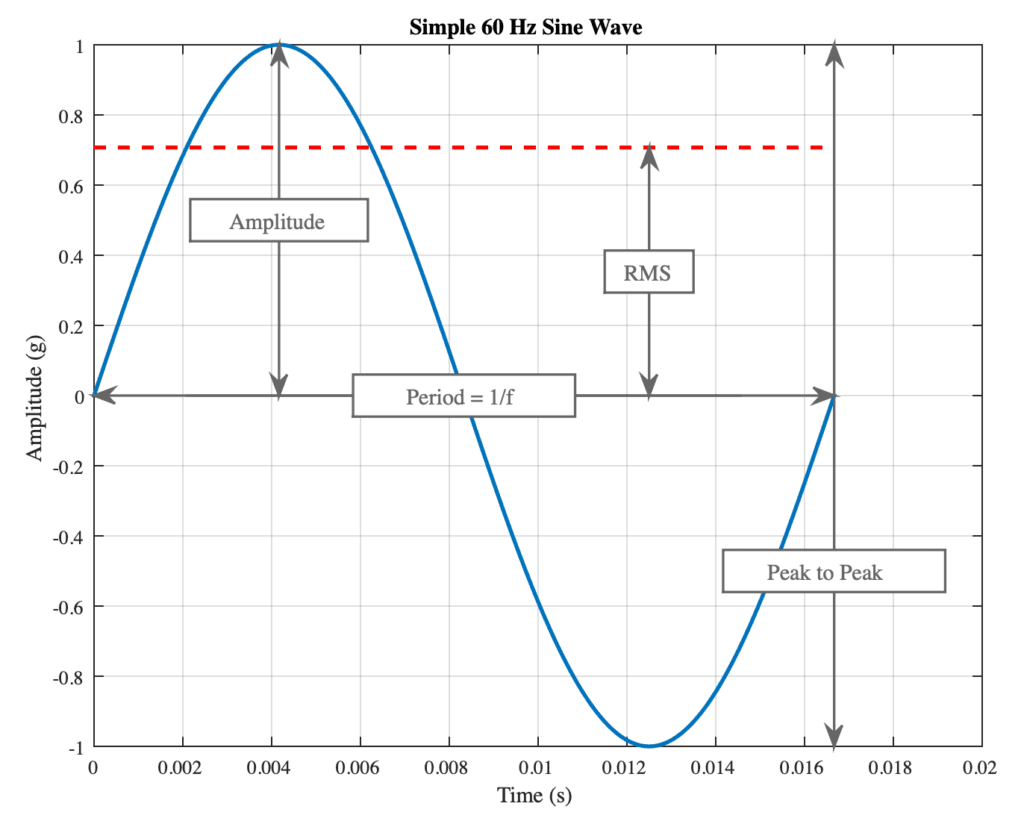

Vibration amplitude

Amplitude defines the magnitude of the machine’s oscillation and is used to judge the severity of the vibration. Oscillations with large amplitude indicate that the vibratory movements are large, fast, or forceful, resulting in more stress on the machine, components, and structure. Amplitude can be measured and specified for three aspects of oscillation: displacement, velocity, and acceleration.

Image credit: Mide Technology

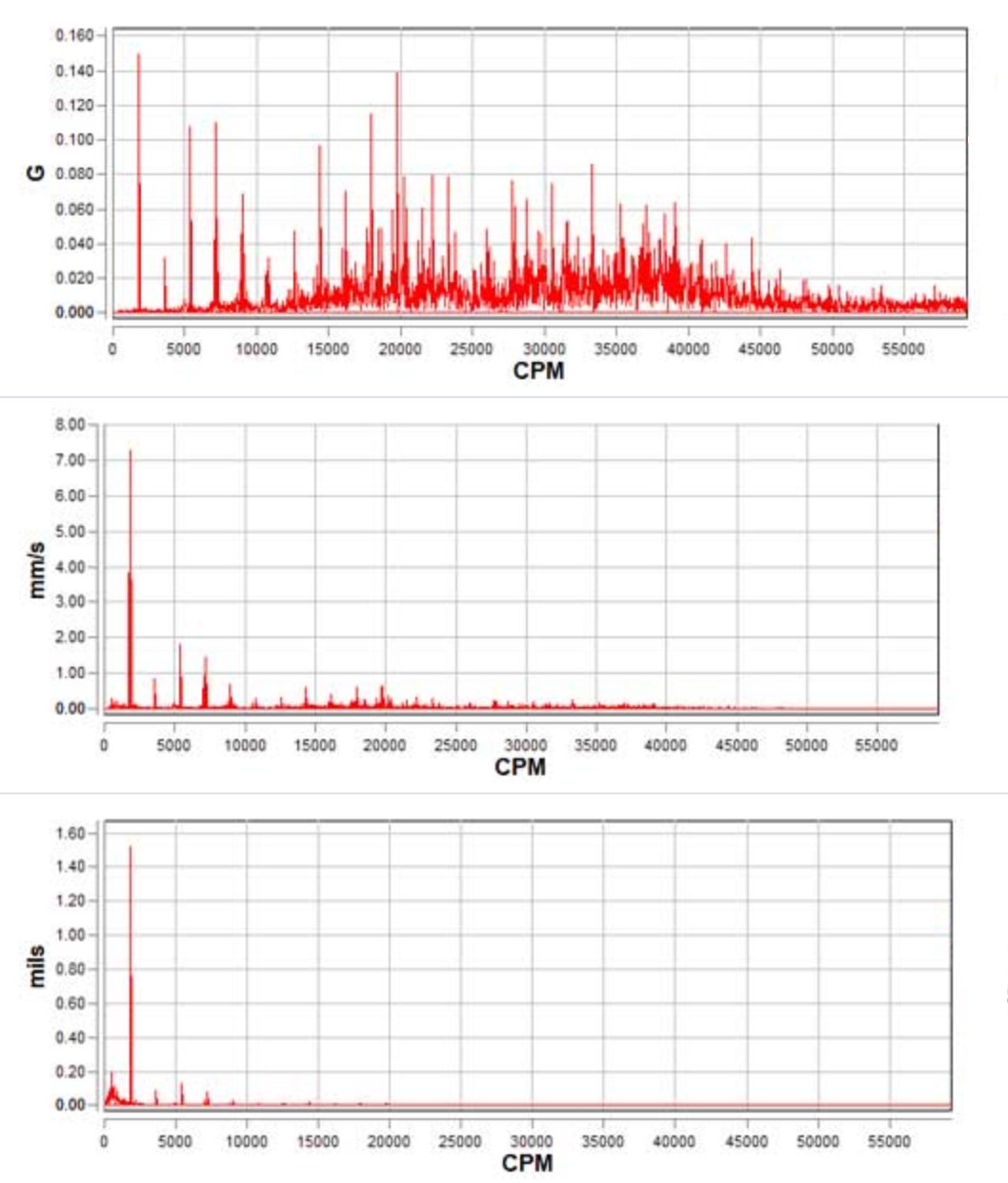

Displacement amplitude

Displacement amplitude measures the distance the vibrating part travels in one direction from a reference position during oscillations. (Note that the peak-to-peak displacement value, which measures total travel in both directions, is sometimes used.) This vibration measurement is important because vibrations with a high displacement amplitude can cause machine components to exceed their yield point and experience catastrophic failure. Displacement measurements are typically used when vibration frequencies are low.

Velocity amplitude

Velocity amplitude measures the speed of the oscillation. This measurement is typically considered the industry standard for evaluating the condition of a machine based on its vibrations, because it takes into account both vibration frequency and displacement. (Recall that velocity is the rate of change of displacement.) In fact, ISO standards refer to velocity amplitude when specifying the severity of machine vibration. Velocity amplitude can be expressed in terms of peak value or, more often, in terms of the root mean square (RMS) value, which is an indicator of the vibration energy.

Acceleration amplitude

Acceleration amplitude is directly related to the force imparted by the vibration and is especially useful for assessing the likelihood of fracture for equipment that rotates at high speed. The high forces associated with acceleration can also cause lubrication breakdown, which can lead to excessive wear, heat, and premature failure. Acceleration is typically measured in “g,” or multiples of earth’s gravitational acceleration.

Image credit: Erbessd Instruments

Leave a Reply

You must be logged in to post a comment.