Image credit: Rotor Clip

Wave springs are gaining acceptance in motion applications, thanks to their ability to provide similar force and deflection characteristics to traditional coil springs, but with significantly reduced working height. Although wave springs can be used in static applications — such as preloading a bearing or mechanical seal — many applications require dynamic movement — for example, to assist with the operation of a valve. When springs are subjected to dynamic loading, the constant cycling between different work heights and forces can cause the spring to experience fatigue — weakening and possible failure of the material.

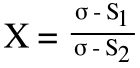

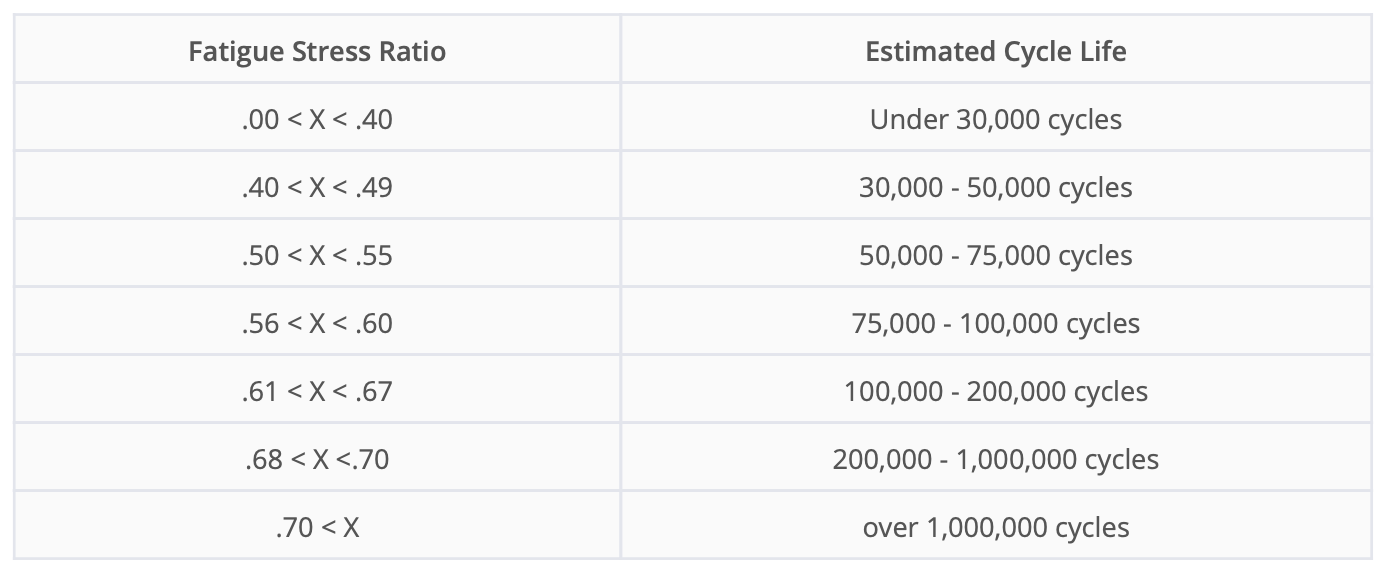

The fatigue life of a wave spring depends on the working (operating) stresses on the spring and on the spring material’s tensile strength. In dynamic applications there are multiple operating stresses (one at each working height), but in most cases, it’s sufficient to use the operating stresses at minimum and maximum loads. These operating stresses are used to determine the wave spring’s fatigue stress ratio.

X = fatigue stress ratio

σ = material tensile strength

S1 = calculated working stress at lower working height (must not exceed σ)

S2 = calculated working stress at upper working height

The fatigue stress ratio is then used to determine the spring’s estimated cycle life.

Image credit: Smalley

The most straightforward way to increase a wave spring’s fatigue stress ratio and, in turn, its estimated cycle life, is to use a material with a higher tensile strength (σ). Wave springs are offered in a broad range of steel, stainless steel, superalloy, and bronze materials, so designers often have the choice of several materials that will meet the application’s tensile strength requirements and withstand any special environmental conditions.

For example, 17-7 stainless steel (a type commonly used for wave springs) provides both corrosion resistance and better fatigue resistance than carbon steel. And Elgiloy, a cobalt-chromium-nickel-molybdenum superalloy provides excellent fatigue resistance and can withstand saltwater and acidic environments.

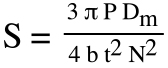

Spring geometry also plays a role in fatigue by determining the working stress the spring sees. Working stress has an inverse-squared relationship to both material thickness (t) and number of waves per turn (N), so increasing either of these will provide a significant decrease in working stress. However, wave spring geometry also affects spring deflection and spring rate, so these must be taken into account.

S = working stress

P = load

Dm = mean diameter

b = material radial width

t = material thickness

N = number of waves per turn

Another way to avoid fatigue and improve cycle life in dynamic applications is to use an interlaced wave spring. In this design, two springs with similar thickness, amplitude, and frequency are interlaced so that the turns of each spring align. This increases the thickness of each wave turn, which provides higher load capacity and better resistance to fatigue.

It’s important to note that in dynamic applications, wave spring manufacturers generally advise that working stress should not exceed 80 percent of the material’s tensile strength. This is to reduce the possibility of the spring relaxing, or “taking a set.” Setting is a condition where the spring is stressed beyond its elastic limit and does not return to its original length. Although setting is usually undesirable, in some cases, a process known as “presetting” is used to increase the spring’s apparent elastic limit.

Presetting is achieved by manufacturing the spring to a longer free height and higher load than is required. The spring is then compressed to a solid — that is, to the point where the various waves touch. This removes permanent deformation that would occur when the elastic limit is exceeded and creates beneficial stresses that cause an apparent increase in the spring’s elastic limit, improving its load capacity at a given height.

Leave a Reply

You must be logged in to post a comment.