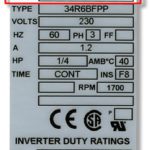

The first place to start when sizing a gearmotor is to determine the required output torque and speed. But once torque and speed are defined, you’ll also want to know the required input power for the motor — particularly if the gearmotor uses an AC induction motor, where the power rating (typically given in horsepower) is used as a key factor in sizing.

Relationship between work and power

Before we look at how to calculate power, let’s review the relationship between power and work.

Work is defined as force applied over a distance:

![]()

W = work (J)

F = force (N)

d = distance, or displacement (m)

Mechanical power is the time rate at which work is done, so work divided by time:

![]()

P = mechanical power (watt)

W = work (J)

t = time (s)

Mechanical power can also be written as:

![]()

Note that distance divided by time (d/t) is velocity, so power can be written as force times velocity:

![]()

v = velocity (m/s)

Power equations for electric motors: metric units

Electric motors produce torque (rather than force) through rotational motion (rather than linear distance), so power is equal to torque multiplied by angular velocity:

![]()

P = mechanical power (W)

T = torque (Nm)

ω = angular velocity (rad/s)

Note that angular velocity has units of radians per second. If speed is given in rotations per minute (rot/min or rpm), be sure to convert rotations per minute to radians per second:

![]()

Converting from Watts to horsepower

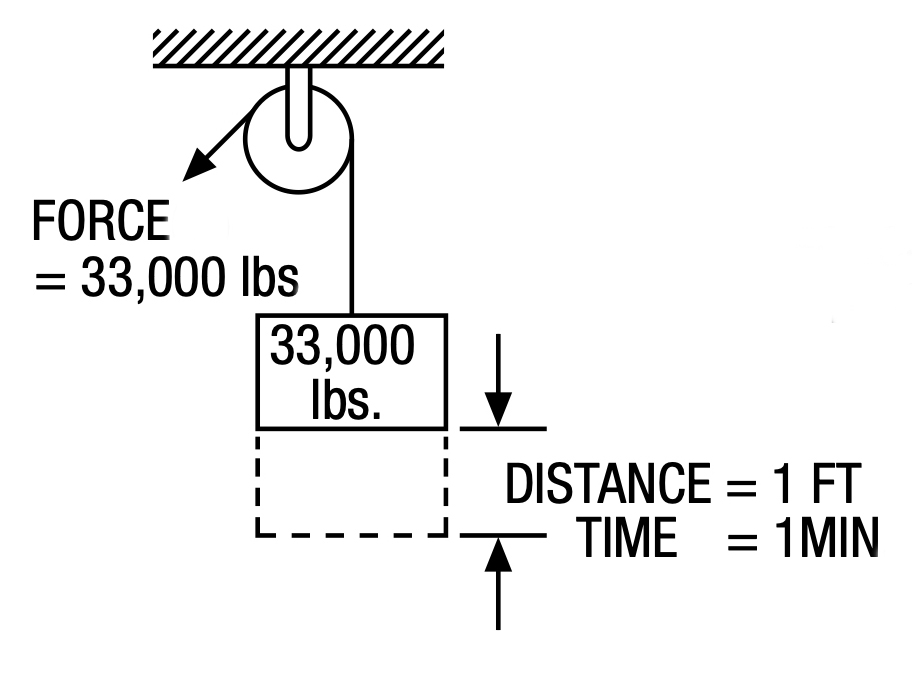

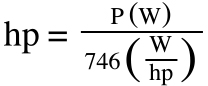

Although the SI unit of power is the watt, in discussions of motor power, the Imperial unit of horsepower is often used.

In the 1780s, James Watt and Matthew Boulton defined 1 horsepower (hp) as 33,000 ft-lb/min, which, is 44,742 Nm/min.

Converting this from Nm/min to Nm/s gives us 746 Nm/s, or 746 Watts. Therefore, to convert power from watts to horsepower, divide the power in watts by 746.

Power equations for electric motors: Imperial units

In gearmotor applications, torque and speed are still often given in Imperial units. In these cases, horsepower can be calculated directly, with the use of a conversion factor:

When torque is given in lb-ft and speed in rpm:

![]()

P = mechanical power (hp)

T = torque (lb-ft)

ω = angular velocity (rpm)

5252 = 33,0000 ft-lb/min ÷ 2π rad/rot

When torque is given in lb-in and speed in rpm:

![]()

P = mechanical power (hp)

T = torque (lb-in)

ω = angular velocity (rpm)

63,025 = 33,000 ft-lb/min * 12 in/ft ÷ 2π rad/rot

Input power for gearmotors

Each equation for mechanical power given above can apply when sizing a gearmotor, depending on what units of torque and speed are being used.

However, when determining the input power required for the motor, the efficiency of the gearmotor assembly at transmitting that power to the load must be taken into account. Therefore, regardless of which equation above is used to calculate the required output power, the required input power at the motor is calculated as:

![]()

η = gearmotor efficiency

Note that efficiency can vary greatly, depending on the motor, type of gearing used, and the gear ratio. For example, gearmotors that use hypoid gearing can have efficiencies of greater than 90 percent, while those that use worm gears can have efficiencies ranging from less than 40 percent up to about 80 percent.

Leave a Reply

You must be logged in to post a comment.