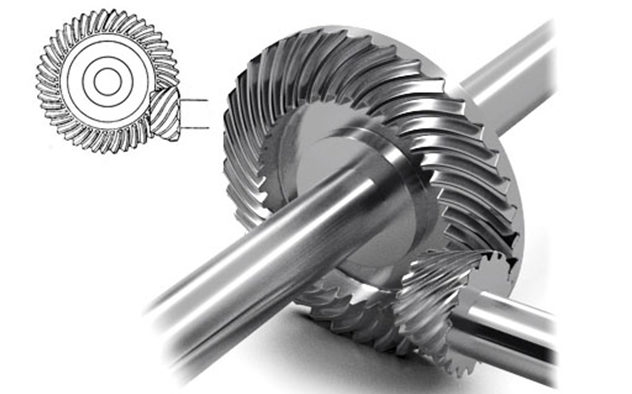

Hypoid gearboxes are a type of spiral bevel gearbox, with the difference that hypoid gears have axes that are non-intersecting and not parallel. In other words, the axes of hypoid gears are offset from one another. The basic geometry of the hypoid gear is hyperbolic, rather than having the conical geometry of a spiral bevel gear.

In a hypoid gearbox, the spiral angle of the pinion is larger than the spiral angle of the gear, so the pinion diameter can be larger than that of a bevel gear pinion. This provides more contact area and better tooth strength, which allows more torque to be transmitted and high gear ratios (up to 200:1) to be used. Since the shafts of hypoid gears don’t intersect, bearings can be used on both sides of the gear to provide extra rigidity.

Image credit: odesie

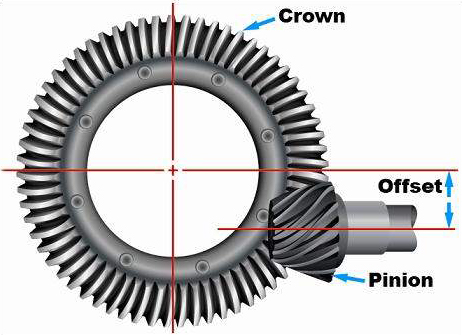

The difference in spiral angles between the pinion and the crown (larger gear) causes some sliding along the teeth, but the sliding is uniform, both in the direction of the tooth profile and longitudinally. This gives hypoid gearboxes very smooth running properties and quiet operation. But it also requires special EP (extreme pressure) gear oil in order to maintain effective lubrication, due to the pressure between the teeth.

This video from Neugart GmbH shows the construction and operation of a hypoid gearbox.

Hypoid gearboxes are generally used where speeds exceed 1000 rpm (although above 8000 rpm, ground gears are recommended). They are also useful, however, for lower speed applications that require extreme smoothness of motion or quiet operation. In multi-stage gearboxes, hypoid gears are often used for the output stage, where lower speeds and high torques are required.

The most common application for hypoid gearboxes is in the automotive industry, where they are used in rear axles, especially for large trucks. With a left-hand spiral angle on the pinion and a right-hand spiral angle on the crown, these applications have what is known as a “below-center” offset, which allows the driveshaft to be located lower in the vehicle. This lowers the vehicle’s center of gravity, and in some cases, reduces interference with the interior space of the vehicle.

This video from MAN Truck & Bus shows how hypoid gears are used in heavy trucks for maximum efficiency and lower fuel consumption.

Leave a Reply

You must be logged in to post a comment.