Christian Fell • POSITAL FRABA | Magnetic rotary-encoder technology is a staple for incremental and absolute motion tracking. Now some manufacturers are offering new encoder geometries based on the technology to give OEMs and machine builders flexibility in the way they incorporate measurement capabilities into products. The encoders don’t require the extreme cleanliness and assembly precision that built-in optical encoders demand, and that reduces manufacturing costs. What’s more, solid-state electronics in these magnetic encoders are more tolerant of shock and vibration than the transparent code discs and optical sensor arrays of optical devices.

More specifically, kit encoders based on the principle of magnetic technology offer price-performance ratios that lie between those of magnetic resolvers and optical kit encoders (built into the motor casing).

| Incremental motor feedback | Optical kit encoder | POSITAL kit encoder | Optical self-contained encoder |

| Size | Small | Small | Relatively large |

| Cost | $-$$ | $$ | $$$ |

| Multiturn range | No | Yes | Yes |

| Sensitivity to moisture and dust | High — Needs clean environment for assembly | Low | Medium. Sealed housing provides some protection |

| Ruggedness | High | High | Code disk and sensors can be damaged by shock and vibration |

| Equipment for assembly? | Yes — $$$ | Yes — $ | No |

| Skilled worker for assembly? | Yes | No | No |

Basics of encoder use for precision motion control

Servomotors (common in robots, lifts and cranes, material-handling equipment, and medical-diagnostic systems) are motors with built-in or closely-coupled rotary motion and position encoders. These sensors provide closed-loop feedback signals that ensure precise speed control and accurate positioning of mechanical components that the motors drive. For brushless dc servomotors, rotary position sensors also provide commutation signals to electronics controlling the flow of electric current to motor stator windings. Besides the servomotor applications mentioned, built-in rotation sensors can help control the motion of wheels in lifts, hoists, and automated guided vehicles (AGVs).

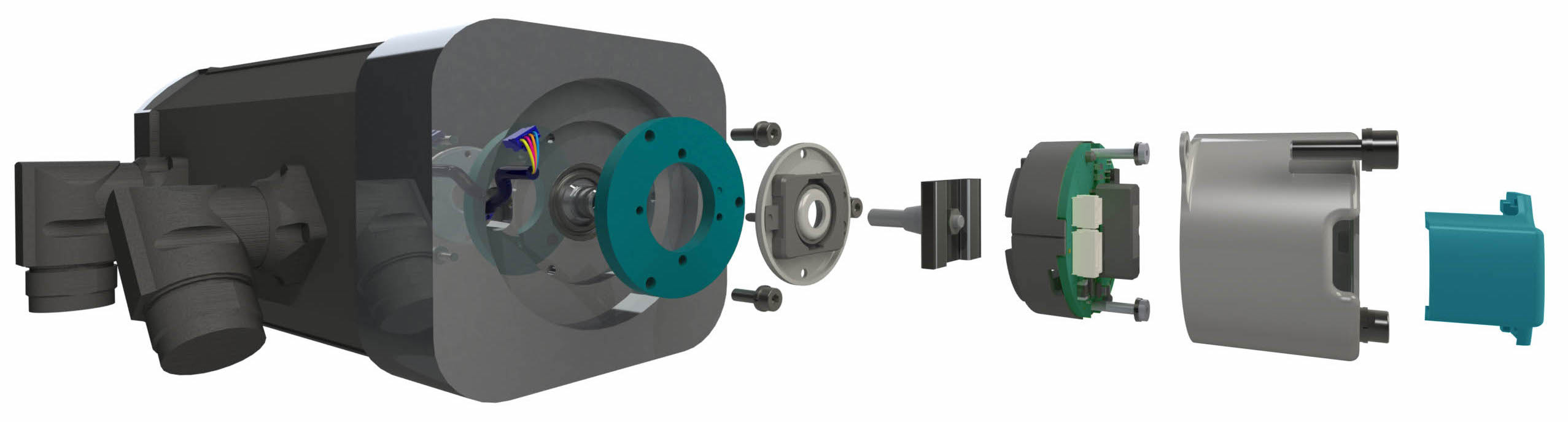

Now some motion-sensor manufacturers have begun to offer manufacturers of servomotors and rotating machinery a rugged and cost-effective option for direct encoder integration. These kit encoders leverage core encoder-maker technologies but in morphologies that allow tight integration into the rotating axes of machines. There are no extra moving parts and there’s no physical contact, either.

Here’s how installation works: The manufacturer mounts permanent magnets on the motor’s rotating shaft. Electronic pickup components (consisting of four Hall-effect sensor elements and a 32-bit microprocessor) are mounted on a single pre-engineered printed circuit board (PCB). The Hall-effect sensors respond to the rotating magnetic field created by the permanent magnets on the motor’s shaft … and output analog signals. Signal-processing software running on the microprocessor filters input data and computes the rotational position of the shaft. Absolute versions have electronic pickups that get energy through Wiegand wires (not backup batteries) that generate powerful voltage pulses in response to the magnet’s revolving field, so the encoder keeps count of complete rotations even without external power.

Optical encoders rely on cleanliness and alignment

Some kit encoders based on magnetic operation can deliver pulse rates to 16,384 pulses per rotation (PPR) at speeds of up to 12,000 rpm. In addition to incremental rotation monitoring, these devices can provide commutation signals (UVW) for 2, 4, 6 or 8-pole brushless dc motors. (Absolute versions deliver 17-bit resolution and multiturn position measurements with a range exceeding a million revolutions.)

For motor and equipment manufacturers, kit encoders based on magnetic operation are compact and straightforward to build into motors and other rotating equipment. Compared to optical encoder components paired with precision servomotors, the magnetic sensors are more tolerant of sensor-to-shaft alignment errors. Some designs also compensate for small positional offsets through a built-in self-calibration capability … so there’s less need for high-precision assembly techniques.

In fact, some servomotor manufacturers and OEMs already use self-contained optical encoders. These typically mount outside of the motor casing and require mounting brackets and coupler to connect to the motor’s shaft. Their self-contained, sealed housings provide protection from dust and moisture, while the use of a flexible coupler can accommodate small alignment errors. While this is an effective solution, kit encoders based on magnetic operation offer OEMs another option for compact built-in position feedback designs — without the need for an externally mounted component or any need to drastically upgrade manufacturing facilities. Plus built-in designs have no need for a separate bearing inside the encoder housing — which further reduces cost and boosts overall design reliability.

Key to magnetic encoder is high-performance signal processing

As mentioned, magnetic rotary-position measurement technologies used in kit encoders can tolerate high levels of shock and vibration. Compared to optical-encoder technologies, magnetic technologies are also much less vulnerable to the effects of oil vapor. Operating temperatures are from -40 to 105 C.

One caveat: Servomotor applications with magnetic brakes can interfere with magnetic-encoder operation. So kit encoders based on magnetic operation require a magnetic shield to isolate the measurement system’s magnetic pickups from the brake’s strong magnetic fields. With a magnetic shield in place, the accuracy of encoder pulse count is unaffected by application of the motor brake.

Onboard diagnostics help ensure reliable operation over the encoder life. Here, magnetic operation enables real programmable versatility. Software-centric microprocessor-based operation gives the kit encoders field-programmable operation. In other words, an OEM can modify the performance characteristics of any kit encoder through software updates — without changing its mechanical or electronic components.

Programmable characteristics in incremental versions include the pulse rate (adjustable from 1 to 16,384 PPR); UVW commutation signals; and rotational direction. Manufacturers can also record in the kit encoder’s memory information such as device serial numbers and date of manufacture for reuse or cloning a machine build.

Kit-encoder programmability lets motor and machine manufacturers configure encoders to perform in myriad ways, so they can standardize on a limited number of standard mechanical designs — even while meeting an array of differing operational requirements with software changes to a given standard encoder.

Encoder suppliers that sell kit encoders offer programming software that runs on PCs or even mobile devices to support encoder self-calibration routines and parameter-setting functions. Some kit-encoder suppliers also offer pre-configuration services for large-volume production orders.

POSITAL FRABA | www.posital.com

Leave a Reply

You must be logged in to post a comment.