HEIDENHAIN’s new absolute modular magnetic angle encoder is for applications needing contamination-resistant encoders with functional safety (FS) for machine feedback. This new ECM 2400 encoder supplements HEIDENHAIN’s portfolio of absolute angle encoders and is designed for machine tool applications that require a sturdy encoder with medium accuracy. The ECM 2400 is suitable for applications with high rotational speeds, angular accelerations, and limited space due to it low overall height of the complete system.

The ECM 2400 works particularly well on B-axis lathes with motorized milling spindles, or on the A and C axes of milling machines where a large hollow shaft encoder is necessary. In general, it is suitable on all rotary axes that require the following attributes:

- Safety-oriented application (mechanical fault exclusion)

- Sturdy angle encoder

- Large inside diameter

- Lower position accuracy than an optical measurement system

- Dynamic positioning accuracy (simultaneous multi-axis machining)

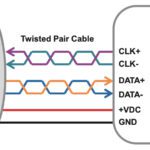

The ECM 2400 encoders are available with EnDat 2.2 interface. In conjunction with a safe control, they can be used as single-encoder systems in applications with control category SIL 2 (as per EN 61508) and with Performance Level “d” (as per EN ISO 13849). The fault exclusion that is implemented in its design has been tested and is ensured under the specified operating conditions.

Existing non-FS interfaces for ECM 2400 encoders includes Fanuc05 and Mit03-4. All of these encoders have an IP67 rating and can be ordered now.

For more information visit www.heidenhain.us/about-us.

Leave a Reply

You must be logged in to post a comment.