Applied Motion Products increases the acceptance of MDX Integrated Servo Motors into industrial motion control applications with UL Recognition on all models. This certification assures users in the United States and Canada that these motors meet high quality standards for electrical safety.

The integrated motors were evaluated according to ANSI/UL standards 1004-1 Rotating Electrical Machines, 1004-6 Servo and Stepper Motors, and 61800-5-1 Adjustable Speed Drives. The certifications are noted under UL file number E472271.

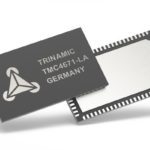

MDX Integrated Servo Motors combine a high torque density, low inertia servo motor with an on-board drive and con

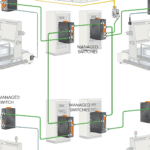

troller. This all-in-one design saves on space, wiring and cost over conventional servo systems with separate motor and drive components. With MDX there are no cables required to connect the servo drive to the motor because the servo drive is integrated into the motor housing. These factors contribute to the reduction in size of control cabinets and easier installation of servo axes in machinery and equipment.

There are currently ten models available that provide 200 or 400 W continuous rated output power and up to 26.6 in.-lb (3.0 N-m) peak torque. Multiple communication options include Ethernet, RS-485 and CANopen.

- Ethernet models support EtherNet/IP and Modbus industrial networking protocols, as well as Applied Motion’s Serial Command Language (SCL) for easy streaming of motion commands from any device.

- RS-485 models support Modbus and SCL.

- CANopen models adhere to the motion profiles defined in the CiA 402 standard.

- All models feature dual-port communications for daisy-chain network connections.

All MDX motors feature stored program execution. Stored programs are created using Applied Motion’s Q Programming language, a simple yet powerful language for generating various kinds of motion, I/O control and machine sequencing, as well as math functions that enable users to create complex motion profiles and control algorithms. Two environmental ratings are available on the MDX motors, including IP65 and IP20. The most popular IP65-rated motors include M12 connectors for all connection points. IP20 rated motors feature pluggable connectors that save cost in high volume, price-sensitive applications.

For more Information, visit applied-motion.com/products/integrated-servo-motors

Leave a Reply

You must be logged in to post a comment.