Among the changes to small motor design over the years has been the use of powerful rare-earth magnets to increase power density, making for smaller and more powerful motors. These motors are finding their way into medical devices, robotics, as well as the intersection of these two. Case in point; a robotic glove.

Ironhand from the Swedish company BIOSERVO TECHNOLOGIES is a soft robotic glove that strengthens the human grip. The gripping force support of the individual fingers is made possible with FAULHABER drives.

Musculoskeletal disorders are a common occupational disease in the EU and North America and are one of the most common causes for long- term absence from work. Work-related upper-limb disorders annually cost 2.1 billion euros across the EU and are responsible for 45% of all occupational diseases. Wearables, clothing enhanced through technology such as the Ironhand, offer an approach for reducing these injuries.

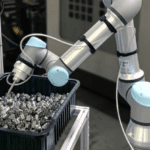

Improved ergonomics at the workplace are increasingly important – both for healthy people as well as for those who are already physically disabled. In addition to solutions that make the actual workplace, meaning the workbench, the desk or the assembly line, more ergonomic, companies increasingly rely on solutions that can be used to augment people. Exoskeletons that are worn on the body like clothing, are one solution.

More power in the hand

This is where the Ironhand, the soft, active exoskeleton for the hands and fingers, comes in. Normally, a gripping action is made possible by the muscles in the lower arm and hand. These muscles pull on tendons, thereby moving the fingers. Ironhand functions in a similar way; pressure-sensitive sensors in the fingertips of the glove detect the gripping action that the user performs with their hand. A computer integrated in the system calculates the additional gripping force necessary and small servomotors pull thin cables in the fingers. The higher the pressure on the sensors, the more power delivered by Ironhand. The settings of the glove can be adapted according to personal preferences as well as the type of work being performed. Data functions enable a digital risk assessment of the hand and the integration of the user in an Industry 4.0 / factory-of-the-future concept. Grip-intensive applications with high ergonomic risk can be identified by analyzing the data during practical work and users can take appropriate countermeasures.

To control the individual fingers, BIOSERVO uses dc micromotors with graphite commutation of the 1741 … CXR series in their Ironhand. The series combines power, robustness and control in a compact form. This is ensured by graphite commutation, high-quality neodymium magnets and the tried-and- tested winding of the FAULHABER rotor. The powerful neodymium magnet gives the motors a high power density with a continuous torque ranging from 3.6 to 40 mNm. The impressive performance data and the compact size open up a wide spectrum of possible applications at an optimized price/ performance ratio.

The glove is available in four different sizes and can be worn by left- and right-handed users. The battery pack, which is worn like a backpack, contains both a computer unit as well as the motors that control the individual fingers. Users can preset various profiles that contain different combinations of sensor sensitivity, force, finger symmetry and locking tendency. Users can change the profile by pressing a button on the remote control, is located in the chest area.

a diameter of just 17 mm and length of 41.2 mm, making them especially suitable for applications with space limitations.

The profile allows the glove to flexibly respond to different requirements encountered during the course of a typical workday. For example, if a person performs slightly stressful tasks during the morning followed by activities in the afternoon that place heavy strain on the muscles, the profile accommodates both conditions. This also allows both male and female users to work with one system. Within milliseconds, the system can provide up to 80 N of gripping force.

The system is also designed not to impede the wearing of personal protective equipment (PPE), such as gloves, fall-protection devices, helmets or warning clothing. For breaks, it can be put on and taken off without external help. The capacity of the batteries in the power supply is designed for a typical working day.

Leave a Reply

You must be logged in to post a comment.