Each year, Design World publishes a Motion Trends issue — a standalone issue that’s the second in its regular four-part Motion Series. Following are links to the expanded versions of some of that issue’s articles.

Connectivity and IoT expand control design functionality (a Motion Trends report)

Connectivity in manufacturing is not a new idea — it’s been around for decades — but what is new in IIoT is the volume and type of equipment (and devices) on the market that now offer connectivity. For an extreme example, there are now smart toilet-paper roll holders that let one know (from a mobile device) that one needs to change the roll. Products like this didn’t exist a decade ago …

Think B2C ecommerce growth is big? Check out B2B (and design-engineering) habits

Forrester Research projects that by 2021, ecommerce will represent about 13% of all U.S. B2B sales. Other research from Statista Inc. confirms this estimate and goes a step further — projecting that B2B ecommerce represented $7.7 trillion in sales globally last year — which is slightly more than triple that of B2C sales …

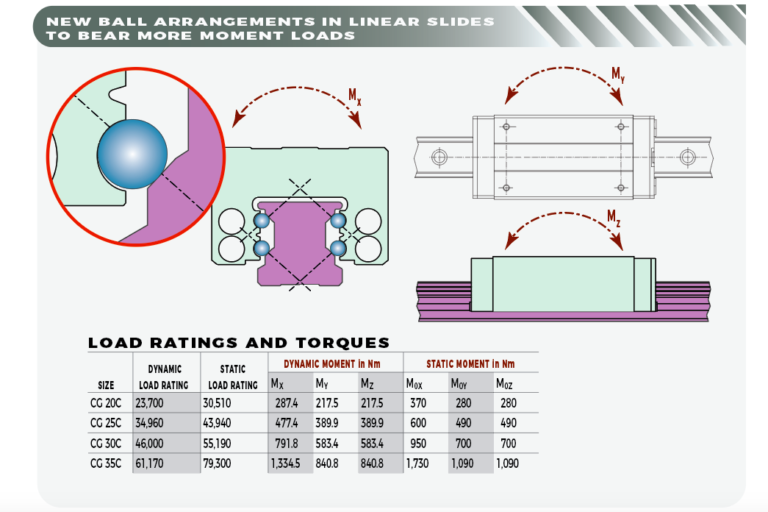

Motion trends: Linear actuators leverage modularity and connectivity

Pre-integration is increasingly common, and actuators lead this trend. Some of the fastest growth is in motion designs destined for compact applications, many of which are being automated for the first time. Some have seen the most rapid growth in applications using NEMA 34 and 60-mm and smaller motors — including those in hybrid stepper, step servo, servo, and BLDC variations …

Linear Motion Trends: Consumer health-monitoring devices and more driving innovation

More mechanical-component manufacturers are selling linear actuators complete with motors — as well as robotic joints complete with motors. Another trend is sensor systems that design engineers can order with mechanical products …

Long-stroke robotic RTU applications pose new challenges for cable carriers

New applications for mechanical devices present unique requirements. Consider the exceptionally challenging application for cable management in robot-transfer units (RTUs) and linear tool-tray transfer systems. RTUs are long tracks to carry robots between workstations. As an inverse solution, linear tool-tray transfer systems move workpieces past a stationary robot for various material handling or fabricating tasks. Both are seeing upticks in use with the general migration to flexible manufacturing …

Engineered materials and upfront design work (are leading trends for mechanical components)

Seals, chains, cable carriers, springs, retaining rings, and general power-transmission (PT) components continue to see new materials at critical surfaces; proliferation of application-specific versions (especially for compression and wave springs); and increasingly practical online purchasing for both off-the-shelf components and customized orders. Here we explore some of these trends …

Distributor insight: Conversation with Warren Osak on motion-control trends

In a recent phone interview, we got to chat with Warren Osak, CEO of Toronto-based Electromate Inc. — a distributor founded in 1986 that focuses on electromechanical motion control. More specifically, Osak’s company sells primarily servo systems and stepper systems — often for demanding or challenging applications requiring high precision, accuracy, and bi-directional repeatability. Electromate also specializes applications destined for harsh environments and high duty cycles. Here’s what Osak had to say about current trends in the motion industry …

Electric motors: Trends in stepper, battery-powered, and integrated motion designs

From induction motors in electric vehicles to tiny coreless dc motors in drug-delivery equipment, electric motors continue to proliferate. Last year we saw consumer products, implantable medical devices, and automation of previously manual tasks spur the most innovation in motor design and use. This year those trends continue — and now we see increased use of servo and stepper motors in robotics …

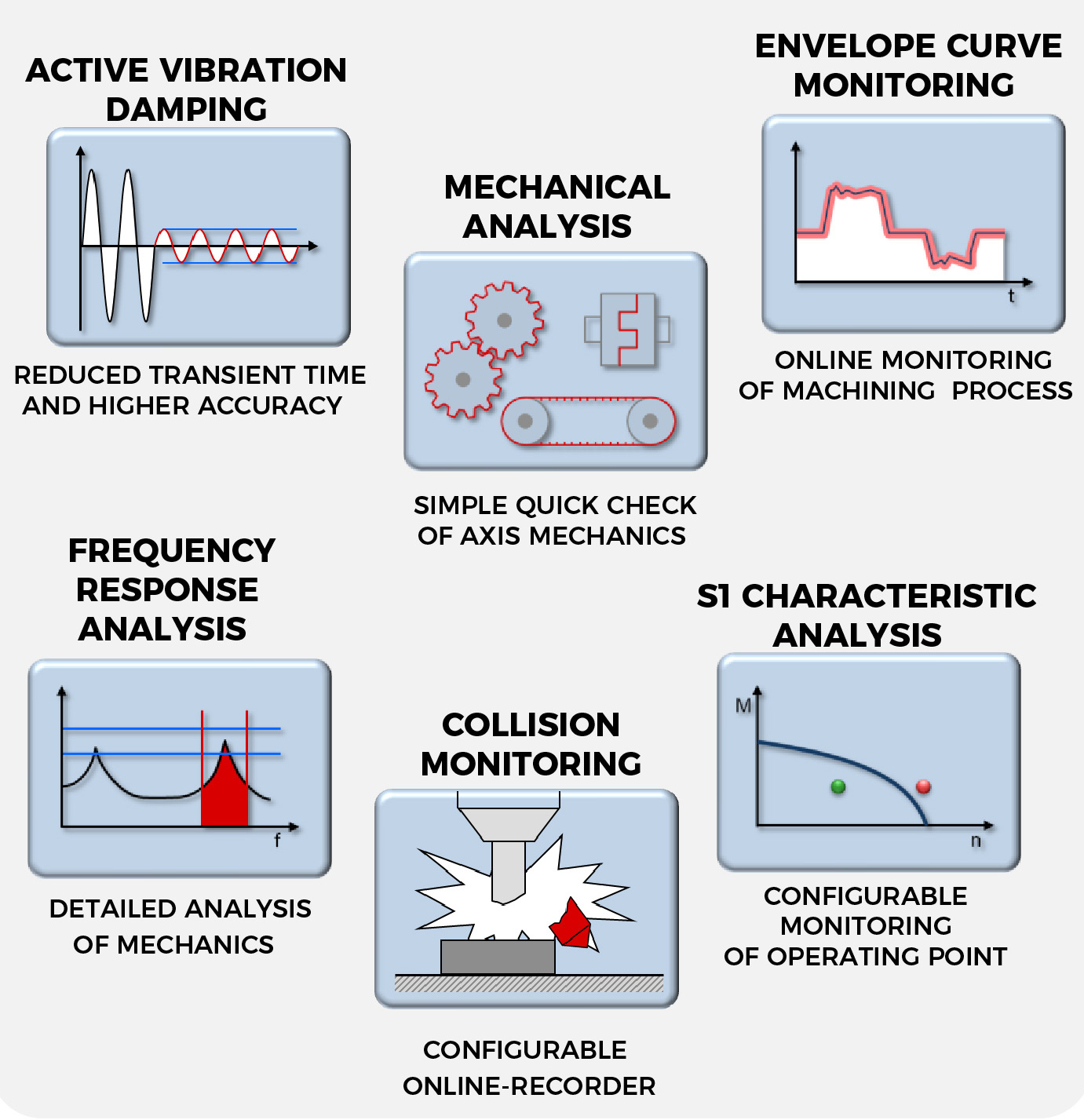

Multi-axis stages and tables: Manufacturer involvement and software yield turnkey motion systems

There’s increasing demand for stages, tables, gantries, and indexing tables with simplicity or turnkey operation — largely because of industry moves toward focused expertise and abstraction. No wonder that motion-system manufacturers are now doing more integration for plant engineers and OEMs …

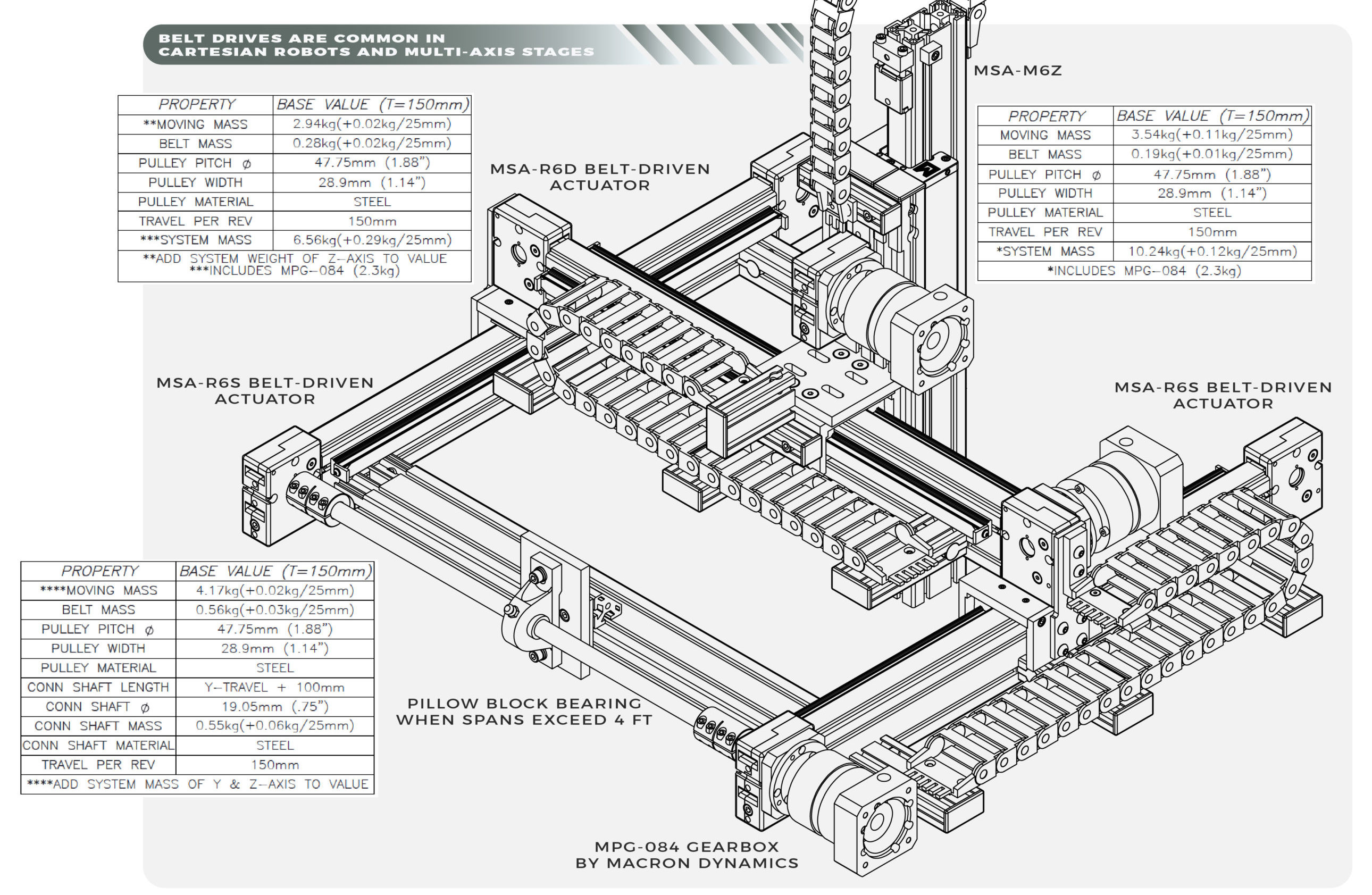

Belt drives offer practical option for performance designs: Motion Trends report

Belt drives include belts and pulleys (as well as clutches and mechanisms for ratio variation) for power transmission between shafts. In cases where these drives function as a conveyor, the load rides on the belt. Elsewhere (as in actuators or machine-axis coupling) belt drives function as the device to convert rotary motion of an electric motor to linear strokes. Key benefits include vibration and shock damping. Global Industry Analysts Inc. USA (GIA) projects that the global market for belt drives will reach $6.9 billion by 2022 — due in large part to demand for heavy industrial, conveyor, and construction equipment …

Gears of new materials and in custom variations (with emerging helical, planetary, and other gearing uses)

Power transmission through gearsets is a mainstay of motion control, as gears allow full use of electric-motor capabilities. Recent years have brought gear innovations with new materials; custom gear variations; and all-new applications for helical, planetary, and strain-wave gearing. We asked several industry experts to share their thoughts these trends and the proliferation of OEM and end-user designs; here’s what they said …

Brakes and clutches: Top trends in IoT — and uses on ac-motor conveyors and servodesigns

Clutches and brakes work in motion systems to stop or hold or index axes — but must do so to application specifications. No wonder then that the trend in this technology is away strictly stock parts. According to Lesli Riehemann, president at Mach III Clutch Inc., customized brakes and clutches are now 75 to 80% of her company’s annual production. What’s more, an increasing number of clutch and brake manufacturers are now looking to supply non-catalog products — and so customization has become normalized …

Leave a Reply

You must be logged in to post a comment.