flexCoder technology

New developments in robotics, automation and many other rotative applications are aiming for ever more compact designs and often cannot be implemented using the standard components available on the market. To prevent restricting the scope of design for the customer, SIKO offers a new flexCoder technology – an encoder system comprising a sensor and rule that can be adapted to the position and shape of the application.

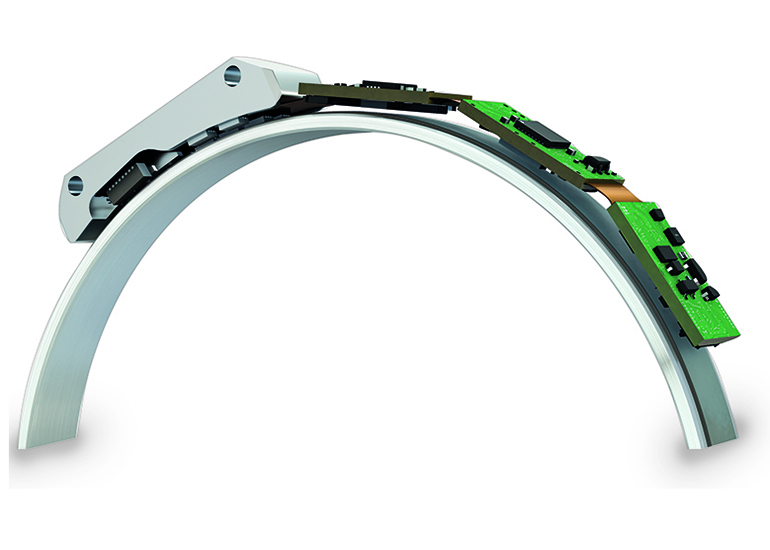

The key factor is that both the sensor and the rule are adaptable. The available SIKO standard can also be applied to a magnet ring or encoder. This allows, for example, the compact sensor mount to be adopted, and modification is only required for attaching the rule on the customer’s shaft. With other applications, a standard SIKO magnet ring is used on the mounting of the flexible sensor array and the evaluation and interface electronics are adapted to the customer’s specific fixing options in the housing. Since the electronics can be both bent and stacked, integration can be very compact. Thanks to these adaptations to the encoder and rule, with regard to the shaft diameter and the fixing options available, the application can be designed more compactly and more uncompromisingly.

Custom solutions – flexible and quickly realized

SIKO has the in-house technology advantage that can be drawn on for both the rule technology and the electronics. The realization time in which the system is customized is skillfully planned to customer specifications. From the initial concept through to the series solution, the project is implemented directly and in short time intervals.

High-resolution, absolute – technical performance

The MSAC200 issues absolute position feedback as soon as it is switched on. For this the SSI interface and the established motor feedback interface, BiSS-C are used. Optionally, the analog real-time signal output can be provided with sin/cos signals 1 Vss.

With ring diameters from 44 mm, an absolute resolution of up to 21 bits is achieved. The high repeat accuracy of 0.01° allows precision positioning at all times.

A further special feature of the MSAC200 is its high installation tolerances. The distance between the sensor and the rule is ≤0.6 mm, and the axial tolerances are of the order of ±0.2 mm. This makes the construction of the complete system easier and allows use in dynamic applications.

Target applications

The MSAC200 is ideally suited for use in applications in which both high resolution and precision are accompanied by the need for flexible adaptation to the customer’s design. These requirements apply to motor feedback, handling and assembly automation, and to robotic systems.

MSAC200 profile:

- Customer-specific ring diameter and type.

- Integration into small installation space

- Absolute resolution of up to 21 bits

- Repeatability 0.01°

- Sensor/ring distance ≤0.6 mm

- BiSS-C and SSI interfaces

- Optional analogue real-time signal output sin/cos 1 Vss for industrial and medical applications, e.g. for motor feedback, handling automation and robotics

For more information, visit: siko-global.com/p/msac200

Author: Mr. Lutz Kettenhofen, MagLine Sales Engineer

Leave a Reply

You must be logged in to post a comment.