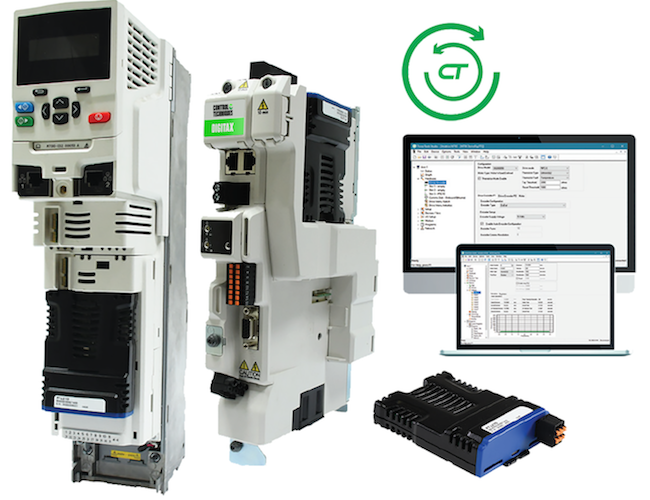

Control Techniques, part of the Nidec group, has launched the next generation of its Motion Made Easy servo control suite. The new PTi210 module, and accompanying software, are designed for use with Control Techniques’ Unidrive M and Digitax HD servo drive platforms. Integrating PTi210 enables designers to access the comprehensive, easy-to-use PowerTools Studio software interface.

Working together, the PTi210 PowerTools integration module and PowerTools Studio software provides a cost-effective way to access simple, fast and effective motion control solutions, including an unparalleled setup and commissioning experience suitable for all skills levels. Professional motion control software engineers, infrequent users, or even someone with no prior servo experience can easily program drives.

The PTi210 module offers five high-speed digital I/O points (three in, two out) that expand on the drive’s onboard I/O. It enables rapid integration for a wide range of applications, including conveyors, rotary knives, electronic gearing and slip compensation.

PowerTools Studio continues this drive for simplicity, by providing designers with tools to program a Digitax HD or Unidrive M drive using a Modbus RU serial port, or on-board Ethernet, depending on the model. The software interface is presented simply, using point-and-click, drop-down menus and drag-and-drop programming as standard. And the software is freely available to download.

For more information visit www.ControlTechniques.us.

Leave a Reply

You must be logged in to post a comment.