Manufacturing plants often contain dozen, if not hundreds, of motors — driving everything from packaging and processing equipment to fans and pumps. Motor control centers allow facilities such as these to centralize control of some or all of their motors into one location.

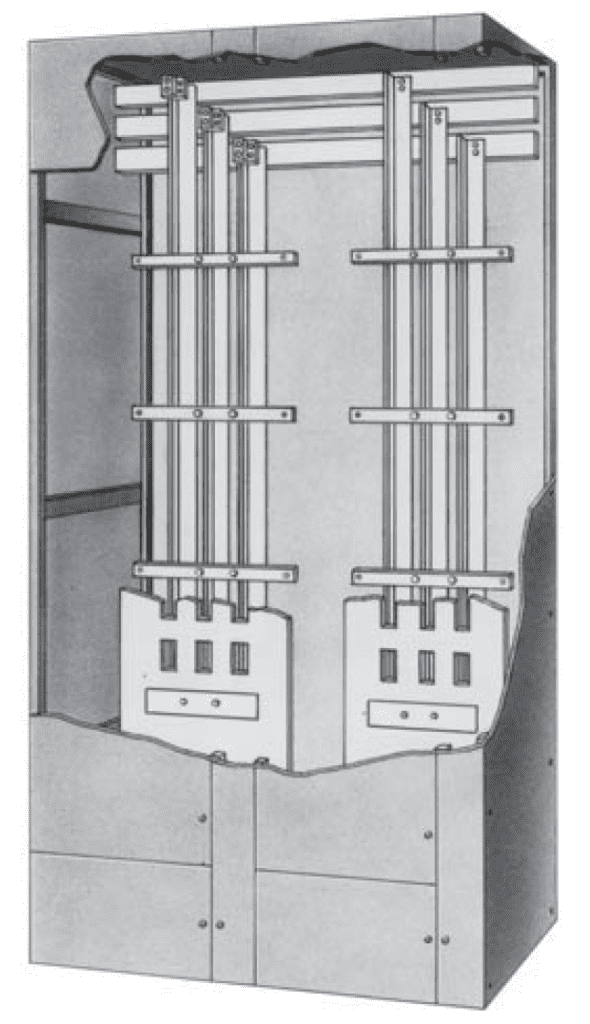

The basic structure of a motor control center (MCC) is a metal cabinet divided into multiple vertical sections that are isolated from one another. The MCC enclosure is typically NEMA or IP rated for protection against ingress of solid and liquid contamination, and if the working environment is harsh — dusty or hot, for example — the motor control center can be located remotely, away from machinery or equipment, or even in a separate, climate-controlled room.

Motor control centers are classified as either low-voltage, for controlling motors from 230V to 1000V, or high-voltage, for controlling motors from 1000V to 15kV.

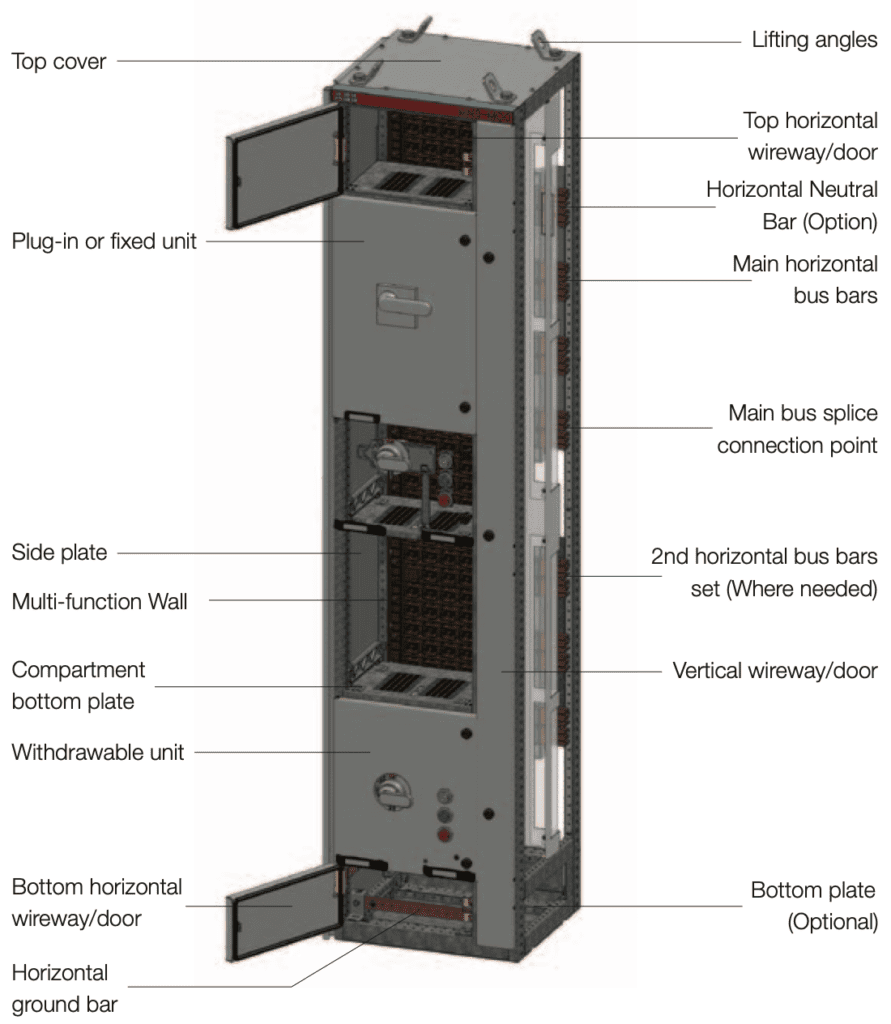

One of the basic functions of a motor control center is to distribute power, which is done via a horizontal main bus — which provides three-phase power from the incoming line — and a vertical bus to each compartment. Common ratings for the horizontal bus are from 600A up to 4000A, while vertical bus ratings typically range from 600A to 1500A. Busses for neutral and for ground are also included as standard on most MCCs.

Image credit: Eaton Corporation

Each section in the motor control center contains sub-sections (often referred to as compartments) for the bus, wireway, and equipment.

Image credit: ABB

The equipment compartment is composed of one or more cubicles that contain the installed hardware for starting and controlling a motor (such as a contactor or motor starter), overload protection equipment, fuses or circuit breakers for short-circuit protection, and a device for disconnecting power.

Motor control centers typically house variable frequency drives (VFDs), although programmable logic controllers (PLCs) and programmable automation controllers (PACs) can also be housed in the equipment compartment. The equipment compartment can also contain hardware to facilitate power factor correction, harmonic correction, and surge protection.

Because they contain high-voltage equipment, motor control centers pose significant safety hazards, but isolating designs and features such as safety interlocks help to minimize risks to personnel and equipment. Most MCC units — both low- and medium-voltage — are also available with measures to prevent arc flash events or reduce the severity and mitigate the impact if an arc flash does occur. Eaton Corporation has published an excellent article explaining arc-resistant and arc-preventative MCC designs.

Motor control centers are now available in “smart” or “intelligent” versions, which use an industrial bus or an Industrial Ethernet network for communication. In addition to significantly reducing wiring — and, in turn, commissioning and startup time — these smart MCCs can also provide data and diagnostic information for remote monitoring, analysis, and control.

Leave a Reply

You must be logged in to post a comment.