You’re probably familiar with Ethernet — the networking protocol that allows computers (typically in office, school, or commercial environments) to share files, browse the internet, and access printers and other hardware connected to the network. Ethernet was developed for high-speed data transmission and is efficient, simple, and flexible. And, it’s arguably the most widely-adopted networking protocol in the world. These factors, along with a low cost of implementation, made Ethernet an attractive networking technology for industrial environments.

A fundamental problem, however, with using standard Ethernet in industrial settings was the fact that the TCP/IP protocol for routing and delivery of data does not inherently provide the real-time, deterministic (guaranteed) performance required in many automation and processing applications. But the physical hardware used in Ethernet networks could.

Industrial applications needed a new, real-time protocol designed to use the physical layers of Ethernet that could also provide deterministic communication between machine controllers, sensors, actuators, and other devices. On that premise, Industrial Ethernet was developed.

Ethernet is defined by the IEEE standard 802.3 and specifies the physical and data link layers of network functionality. TCP/IP is a suite of protocols used on top of the Ethernet data link layer that enable communication over Ethernet. TCP is the transport control protocol, which ensures data packets are delivered completely and error-free. IP is the internet protocol, which routes data packets based on their IP address.

Image credit: PCMag Digital Group

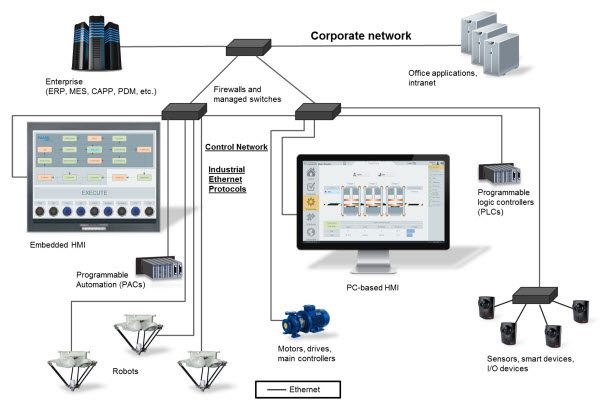

Industrial Ethernet refers to a set of Ethernet protocols that are based on the standard Ethernet hardware (the physical and data link layers) and internet protocols (networking and transport layers), together with a proprietary application layer. The application layer protocol ensures the correct data is transmitted and that it’s received when and where it’s needed for a specific operation.

In the same way that standard Ethernet allows file sharing and access to networked devices in an office, Industrial Ethernet protocols allow controllers to access data within drives, PLCs, workstations, and I/O devices on the factory floor.

Industrial Ethernet protocols take one of three approaches to provide determinism with an Ethernet-based structure. The first such architecture — known as Standard Software/Standard Ethernet — uses standard Ethernet with the TCP/IP protocol, but with mechanisms built into the top (application) layer to enable real-time communication. Ethernet/IP is based on this architecture.

Another architecture — known as Open Software/Standard Ethernet — uses standard Ethernet layers with new (standard) protocols that manage access to the network and synchronize the data being sent from each node (device) to ensure priority data is sent first. Ethernet POWERLINK uses this architecture.

The third architecture used by Industrial Ethernet protocols — known as Open Software/Modified Ethernet — is based on standard Ethernet hardware, but uses new protocols and additional, complementary hardware to ensure determinism. EtherCAT, SERCOS III, and PROFINET IRT all use this architecture, but do so with different hardware and transport mechanisms.

In addition to these architectural modifications, Industrial Ethernet often requires more robust hardware, such as cables and connectors, than are used in standard Ethernet, to withstand the harsh environmental conditions found in most industrial settings. Many Industrial Ethernet applications also require careful shielding, grounding, and filtering to handle electromagnetic interference (EMI, or noise) common in factory settings.

Leave a Reply

You must be logged in to post a comment.