Regent Controls, a Carlyle Johnson Company, now sells a SmartSense24 Sensorless Brake or Clutch Status Monitor.

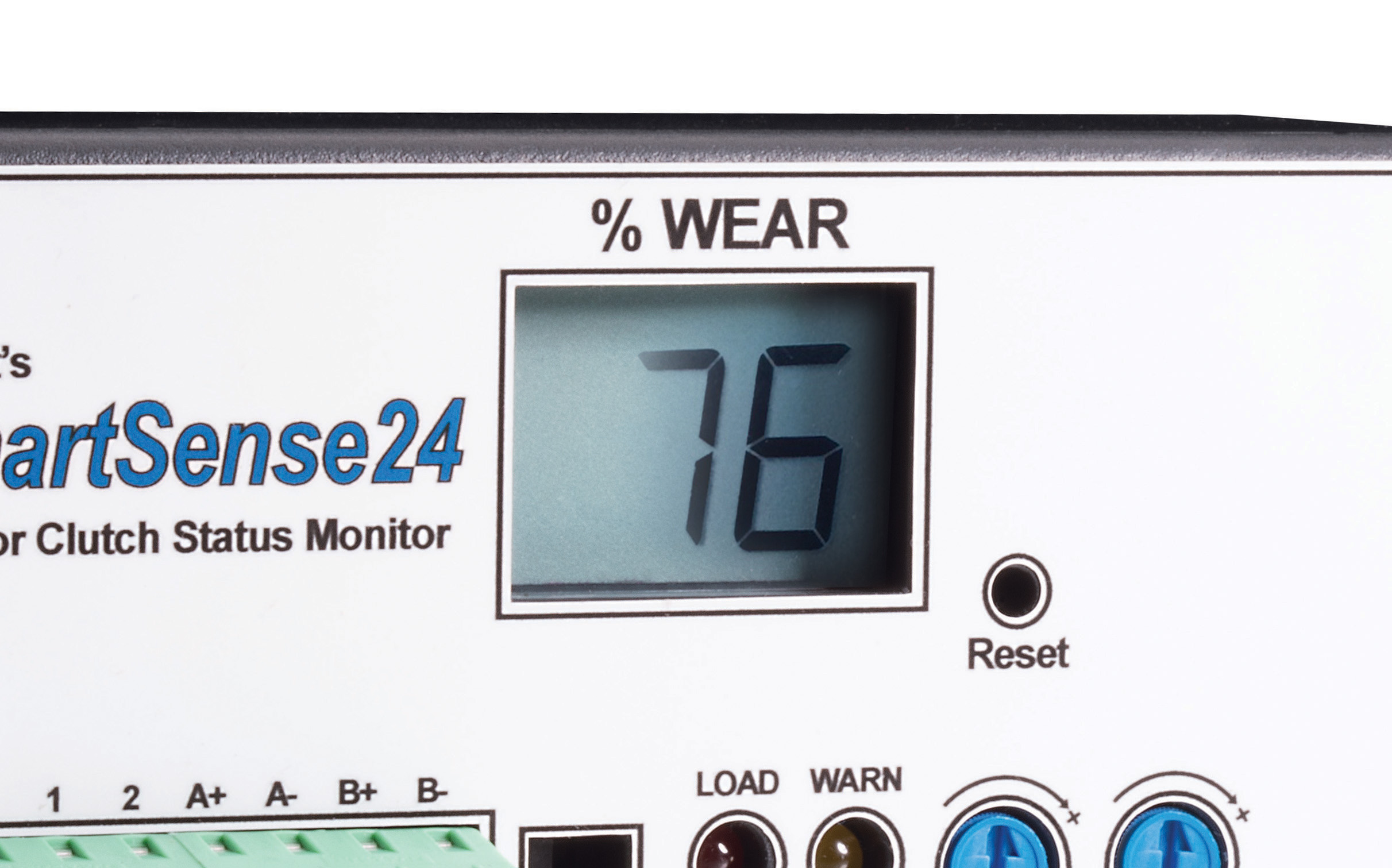

The first product of its kind, SmartSense24 controls and monitors spring-applied electrically-released brakes and clutches — increasing the life of these motion components. The controller provides real-time status and wear condition on an LED display by electronically sensing armature movement after power is applied

The amount of wear as a result of cycle rate usage is then translated to the display. In addition, SmartSense24 automatically controls the amount of voltage the brake or clutch is receiving, and can reduce the holding voltage up to 70% … which reduces coil heating when the brake is disengaged.

SmartSense24 also emits a 24-V output signal when brake/clutch movement has begun, verifying disengagement and enabling remote monitoring of the armature, allowing precise timing between brake/clutch disengagement and motor starting or stopping.

A visual warning display appears when the brake or clutch has fewer than 1,000 cycles remaining, enabling proper timing for clutch or brake replacement and cost-containment. It is all-solid-state (with no relays or contacts to fail) and can reliably operate 24 hours a day, 365 days a year.

With SmartSense24, engineers and system managers can replace brakes and clutches after maximizing the lifecycle of the part, and before catastrophic failure occurs.

“The percentage-of-wear display saves maintenance and downtime costs that typically occur when brake or clutch replacement is guesswork,” said Brian Bylo of Regent Controls. “Now it’s possible to monitor, track, and predict when brakes or clutches should be replaced.”

With SmartSense24, brake and clutch monitoring for the entirety of the wear cycle is now trackable and scheduling maintenance before a safety threshold is breached is now a simple matter of checking the display. For more information on the SmartSense24 from Regent Controls, visit www.regentcontrols.com.

Regent Controls, a Carlyle Johnson Company, was founded in 1947 by Wendell E. Carroll, an electrical engineer known for his design of one of the first all-solid-state industrial machine timers. Regent’s professional teams now design and manufacture a full line of clutch and brake controls, timers, and relays, expanding Carlyle Johnson’s product offerings to include complete, integrated, power transmission and drive solutions. Additional company information is available at www.regentcontrols.com.

Headquartered in Bolton, Connecticut, the Carlyle Johnson Machine Company, LLC. designs, manufactures and services custom brakes, clutches, and complete power transmission systems. The company combines the latest technology with more than a century of manufacturing experience and focuses on advanced engineering and customer service. The company also performs engineering research and prototype development for unique applications, including parts that will operate in deep space, on the ocean floor, and all points in between. Carlyle Johnson remains dedicated to the technological challenges of the future, and to meeting the needs of those to come. Carlyle Johnson is AS9100D/ISO 9001:2015 certified. Additional company information is available at www.cjmco.com.

Leave a Reply

You must be logged in to post a comment.